Carbon nanotube-carbon fiber multi-scale reinforcement as well as preparation method and application thereof

A technology of carbon nanotubes and carbon fibers, which is applied in the field of preparation of carbon nanotubes-carbon fiber multi-scale reinforcements, can solve problems such as uneven distribution, irregular structure, and many impurities, and achieve improved bonding effect, strong practicability, and high technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

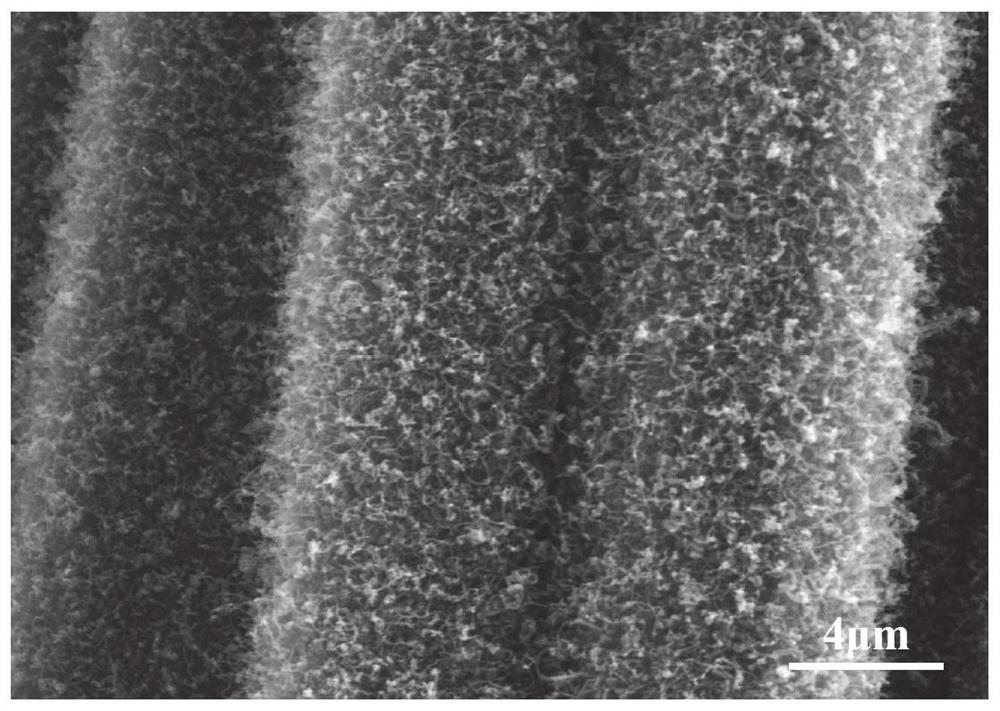

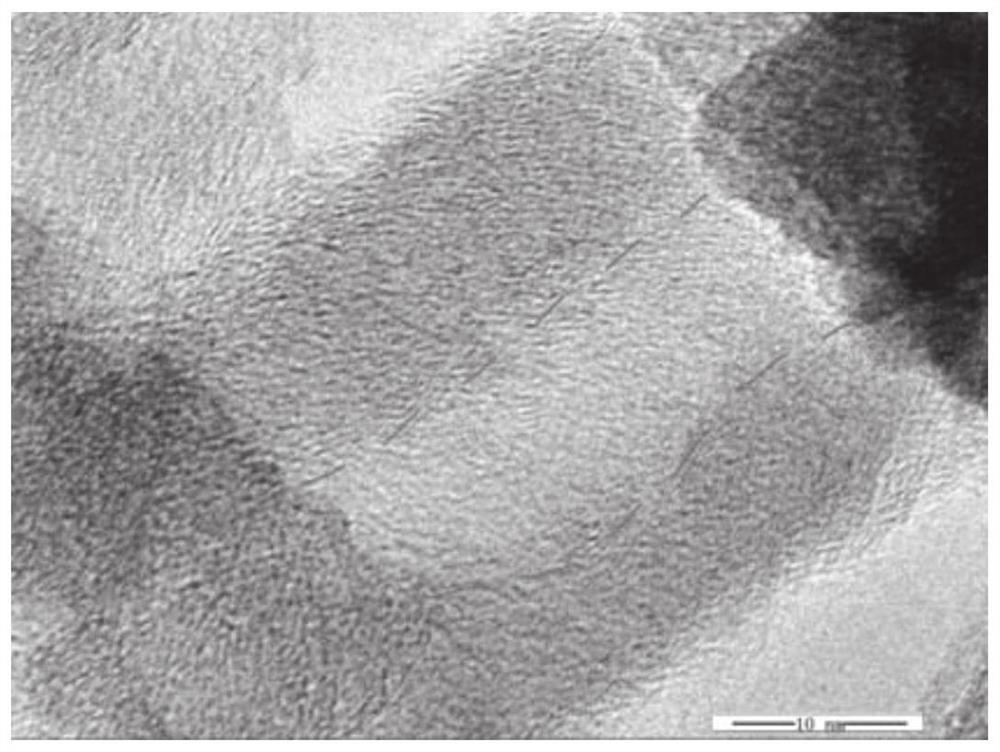

[0038] As introduced in the background technology, in view of the problems of uneven distribution of carbon nanotube network, irregular structure, and formation of amorphous carbon impurities in the process of catalyzing the growth of carbon nanotubes on the surface of continuous carbon fibers with various commonly used catalysts in the prior art, this paper One embodiment of the invention proposes a method for preparing a carbon nanotube-carbon fiber multiscale reinforcement, comprising the following steps:

[0039] soaking the surface-activated carbon fiber tow in the catalyst precursor solution, and drying to obtain the carbon fiber tow with the catalyst precursor attached to the surface;

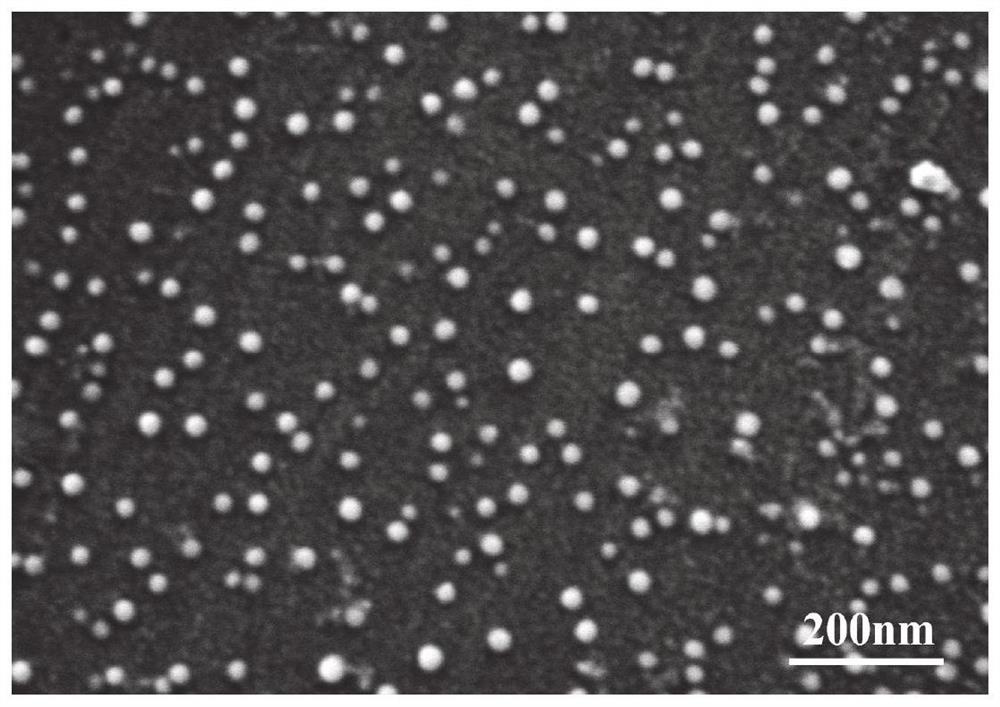

[0040] Reducing catalyst precursors to nano-metal particles, namely catalysts;

[0041] Using the CCVD process, the metal particles catalyze the decomposition of acetylene in the tube furnace and form a carbon nanotube network structure on the surface of the carbon fiber to obtain a carb...

Embodiment 1

[0077] Step 1: The purchased Toray T700 carbon fiber tow is drawn into the tube furnace by a motor, and under the protection of nitrogen, it passes through the furnace chamber with a temperature controlled at 700°C at a wire speed of 15cm / min to remove the surface of the fiber The sizing agent is then collected by a wire collecting machine;

[0078] Step 2: Put the desizing carbon fiber obtained in step 1 into the ammonium dihydrogen phosphate solution with a concentration of 5wt%, and perform electrochemical oxidation with graphite as the cathode and carbon fiber as the anode. The oxidation time is 80s and the current intensity is 0.4A. The oxidized fiber bundles are oven-dried at 70°C;

[0079] Step 3: Weigh an appropriate amount of copper nitrate and ferric nitrate hydrated crystals, and prepare a solution with absolute ethanol as a solvent. The concentration of Cu ions in the solution is 0.0375 mol / L, and the concentration of Fe ions is 0.0125 mol / L. Then put the carbon f...

Embodiment 2

[0086] Step 1: The purchased Toray T700 carbon fiber tow is drawn into the tube furnace by a motor, and under the protection of nitrogen, it passes through the furnace chamber with a temperature controlled at 700°C at a wire speed of 15cm / min to remove the surface of the fiber The sizing agent is then collected by a wire collecting machine;

[0087] Step 2: Put the desizing carbon fiber obtained in step 1 into the ammonium dihydrogen phosphate solution with a concentration of 5wt%, and perform electrochemical oxidation with graphite as the cathode and carbon fiber as the anode. The oxidation time is 80s and the current intensity is 0.4A. The oxidized fiber bundles are oven-dried at 70°C;

[0088] Step 3: Weigh an appropriate amount of copper nitrate and ferric nitrate hydrated crystals, and prepare a solution with absolute ethanol as a solvent. The concentration of Cu ions in the solution is 0.025 mol / L, and the concentration of Fe ions is 0.025 mol / L. Then put the carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com