Process for manufacturing a bearing

a manufacturing process and bearing technology, applied in the direction of shaft assembly, rotary machine parts, mechanical equipment, etc., can solve the problems of micro cracks forming in the hard facing material, and achieve the effects of more radial space, more loading capacity, and strong and ruggedness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

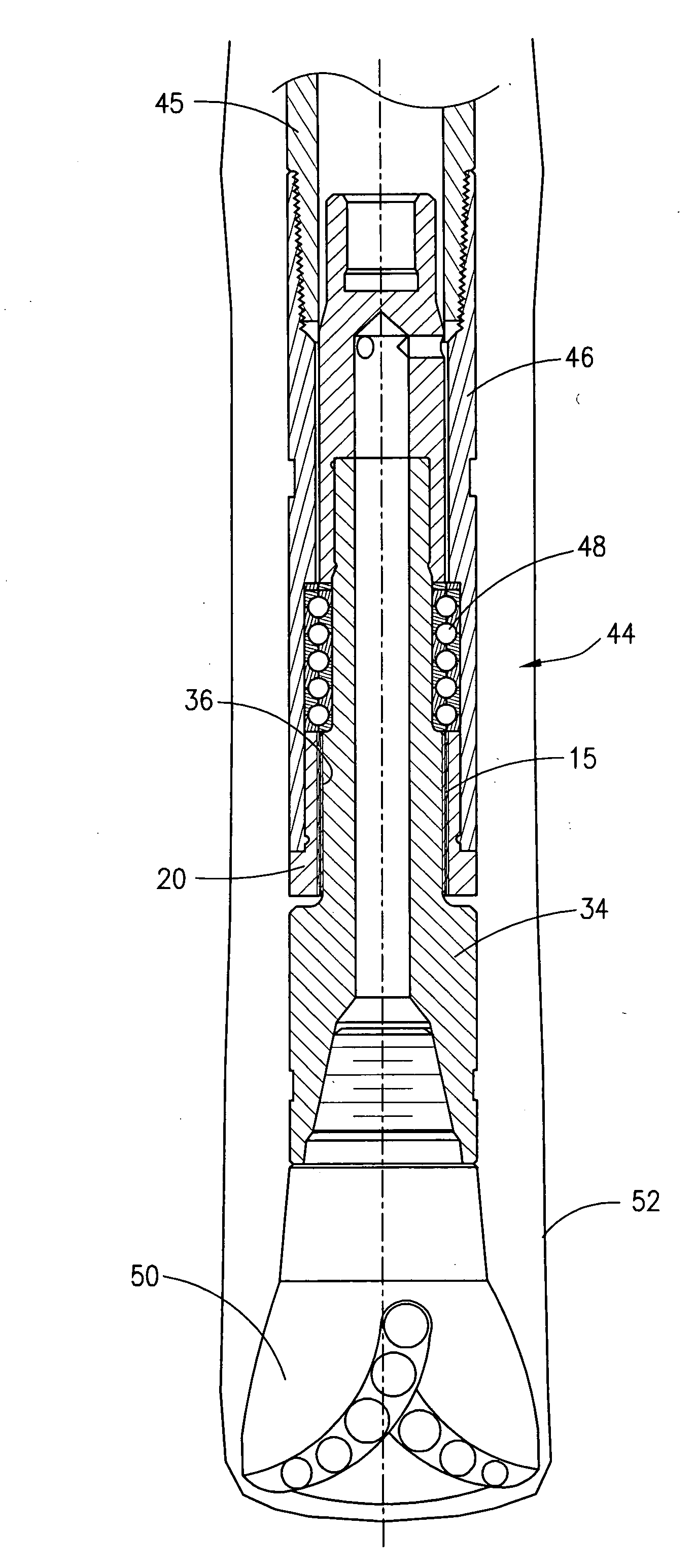

[0038]Referring now to FIG. 1, a cross-sectional view of a core sleeve 2 of the present invention is shown. The core sleeve 2 is made up from easy weldable and machinable material such as carbon steel in the preferred embodiment. The core sleeve 2 can also be constructed of a hard plastic. The core sleeve 2 has an outer diameter surface 4 and an inner diameter surface 6. As will be more fully set out, it is important to retain an accurate measurement of the outer diameter surface 4.

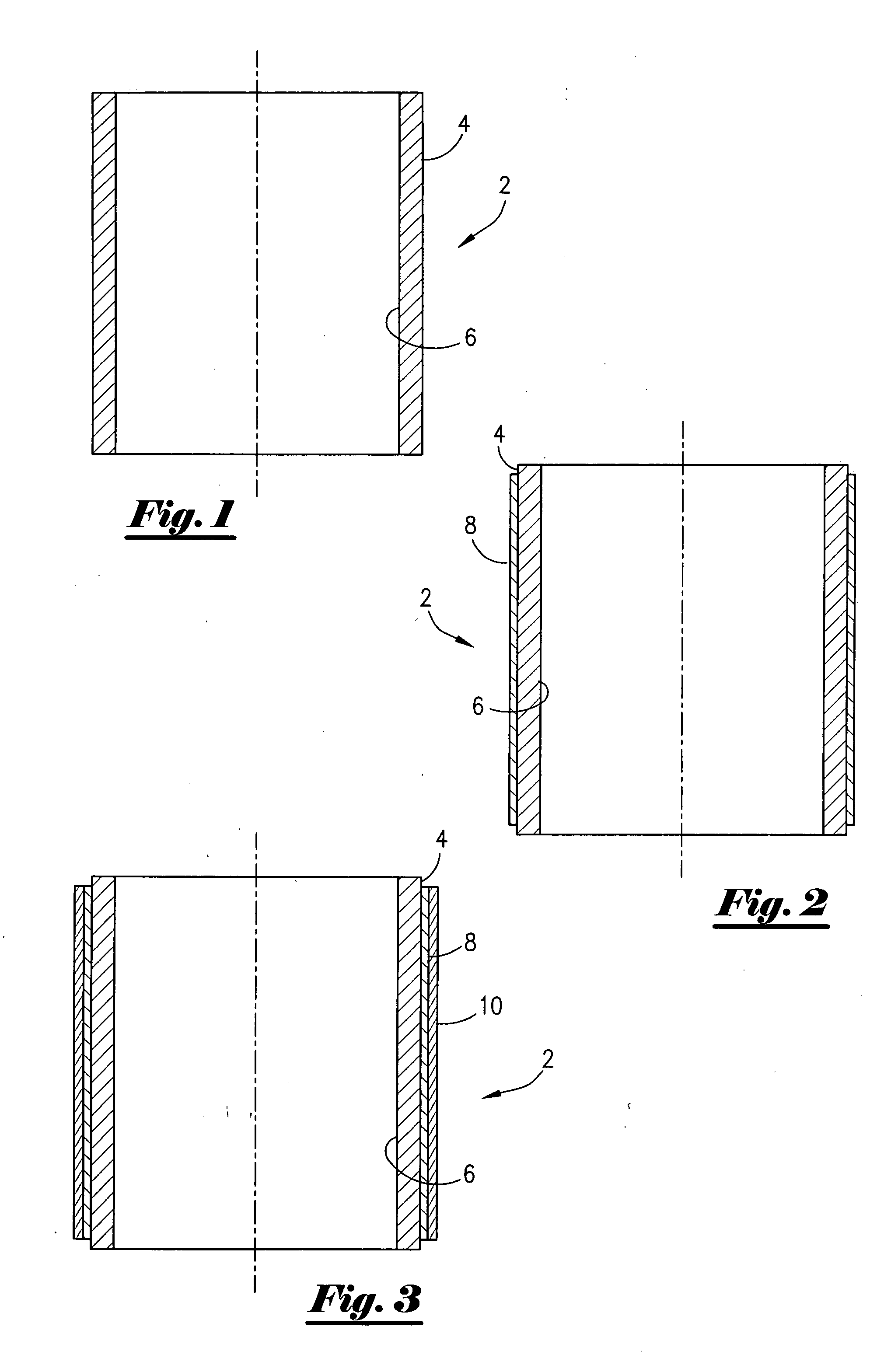

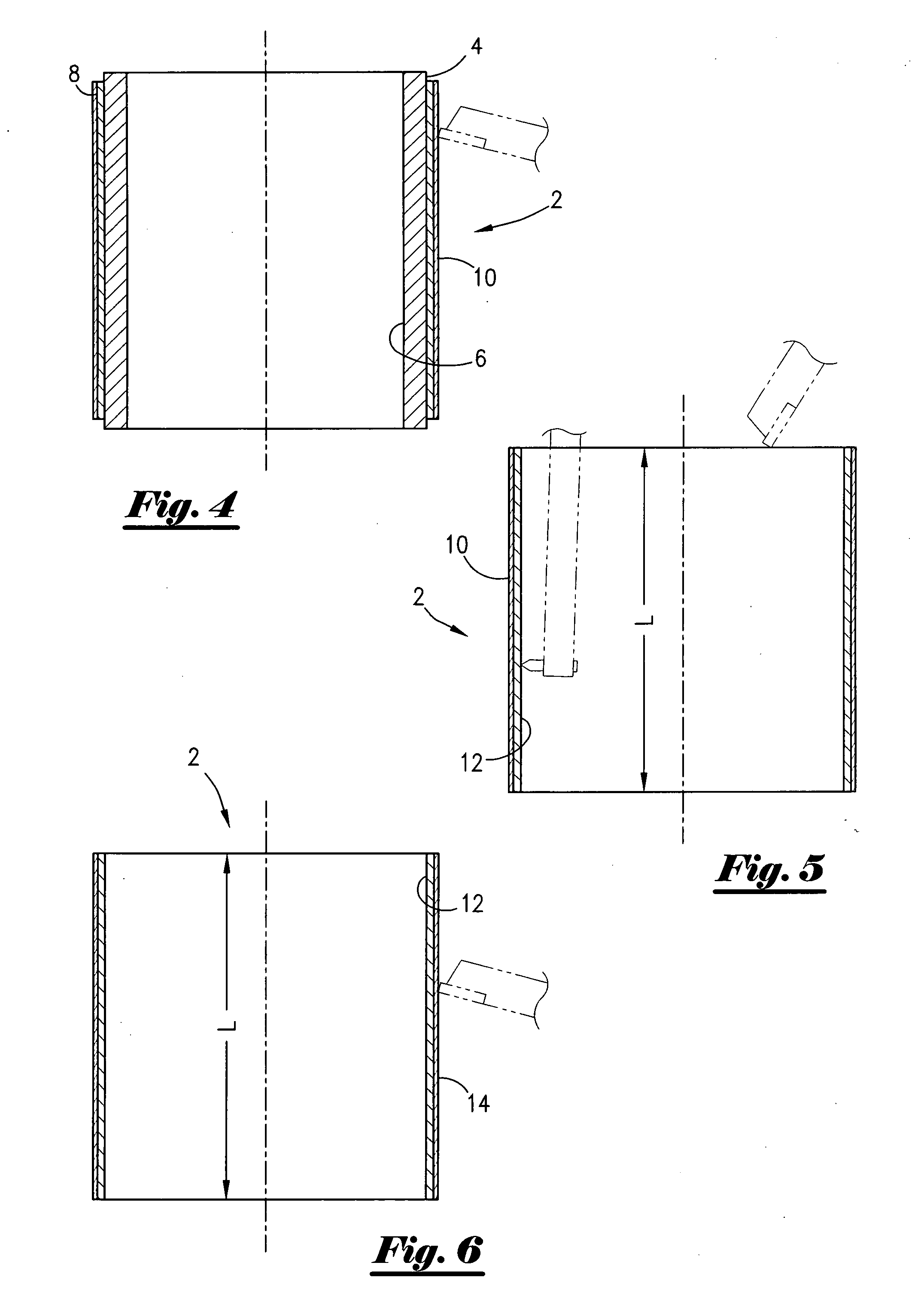

[0039]FIG. 2 is a cross-sectional view of the core sleeve 2 of FIG. 1 with a first coating applied thereto. More specifically, the operator will apply a layer of hard facing to the outer diameter surface 4. In the most preferred embodiment, the fusion process is utilized. An oxygen settling process or a laser process, both of which are commercially available, can be utilized in this hard facing step. In the most preferred embodiment, the laser process is utilized as set out below. Also in the most preferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com