Method of manufacturing double-distortion arc box body structure

A technology of box structure and manufacturing method, which is applied in the direction of arched structure, dome structure, arched beam, etc., can solve the problems of low production efficiency, large space occupation, inaccurate manual segmental sampling, etc., and achieve the external dimension precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is an example of the production of the entrance gate of Caofeidian in Tangshan.

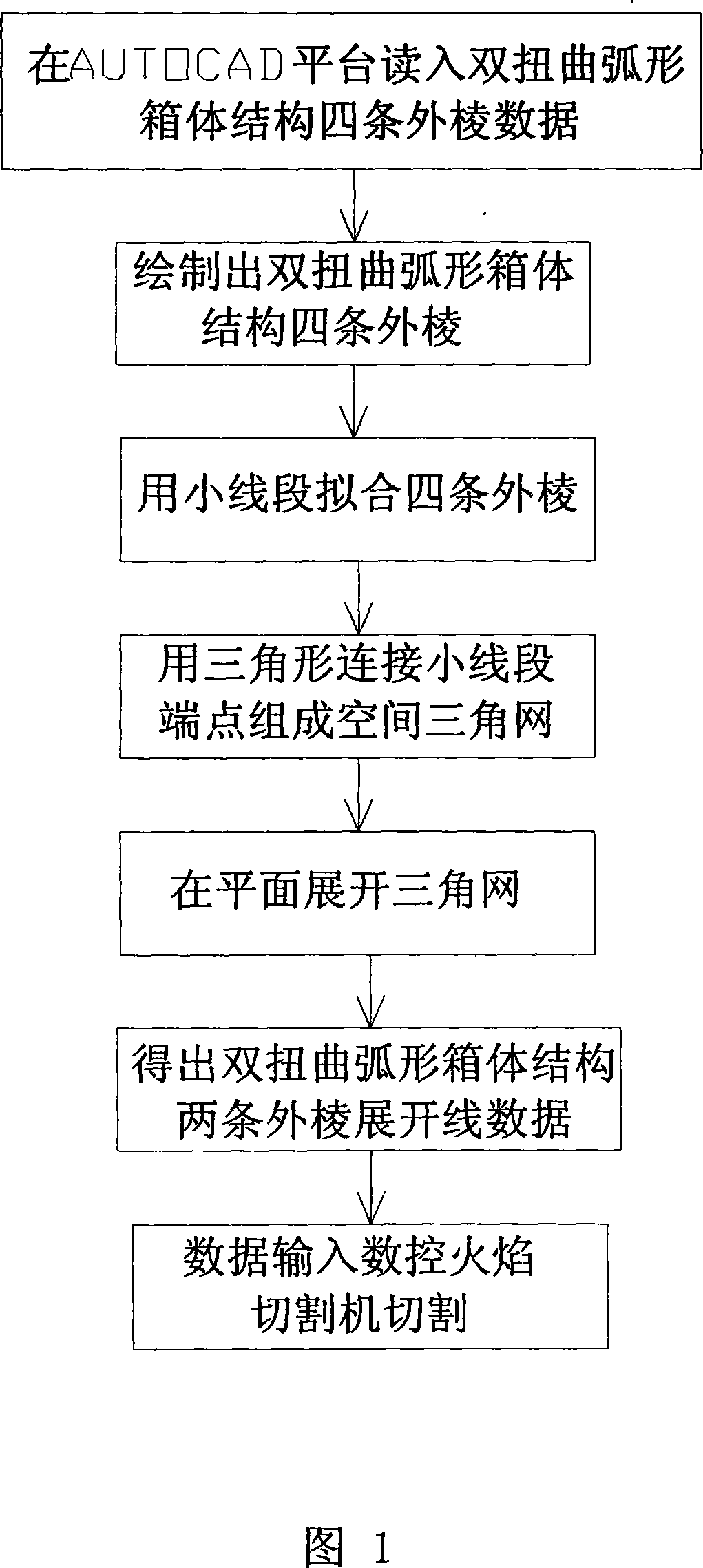

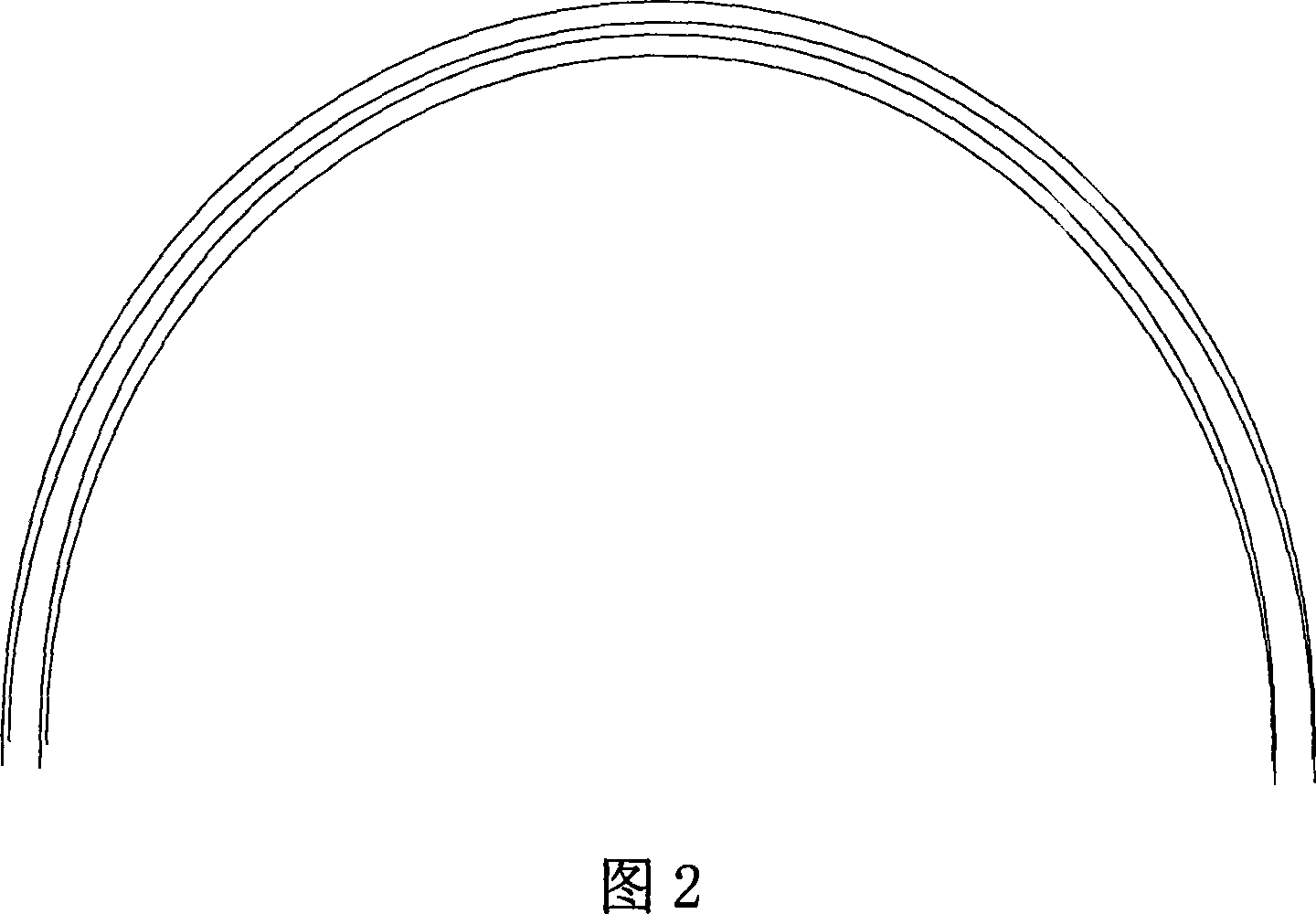

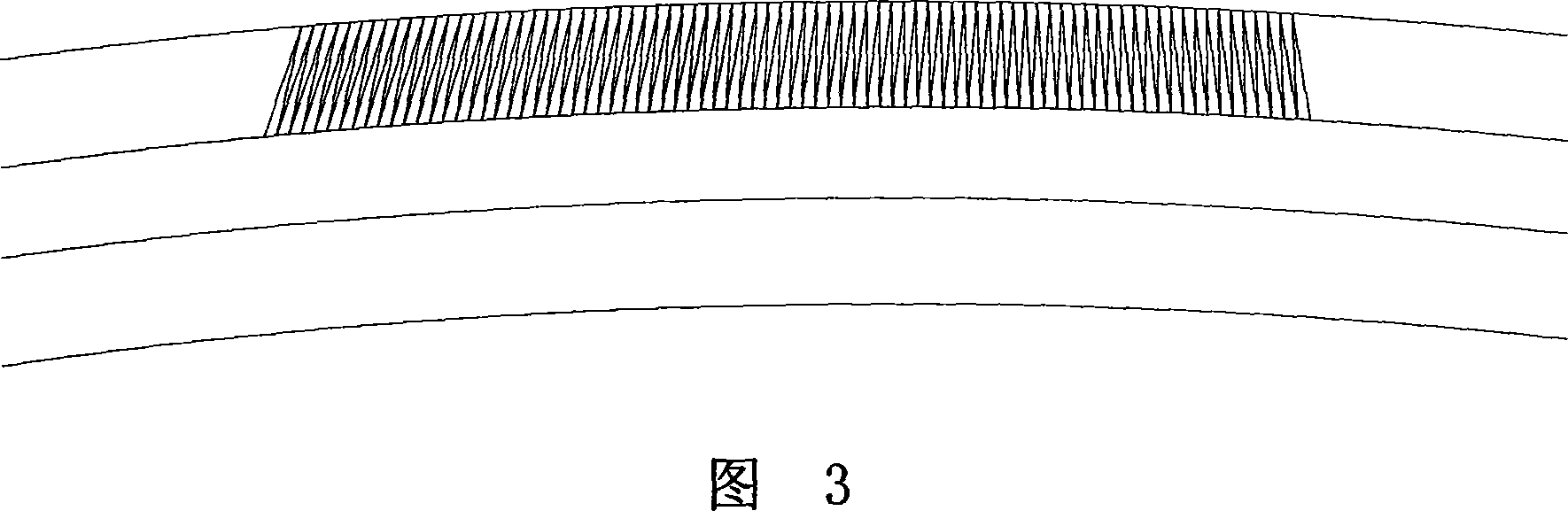

[0032] 1. Blanking and cutting. Referring to attached drawing 2, first draw the four outer edges of the double-twisted arc-shaped box structure on the AUTOCAD platform according to the design requirements. As shown in Figure 3, according to the differential principle, any curve can be regarded as a small straight line segment with different slopes, and any straight line segment and a point outside the straight line determine a surface, so the spiral surface can be regarded as composed of a large number of triangles. See accompanying drawing 4, read out the vertices of each spatial triangle, merge each small triangle into a plane figure in the plane, read the triangle data in the plane into the plane CNC flame cutting machine, and the plane CNC flame cutting machine The data draws the cutting trajectory for cutting.

[0033] Please refer to Figure 1 for the specific process:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com