A simple household winder and its production method

A winding machine, a simple technology, applied in the field of household textiles, can solve the problems of difficult production of winding, and achieve the effect of convenient operation and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

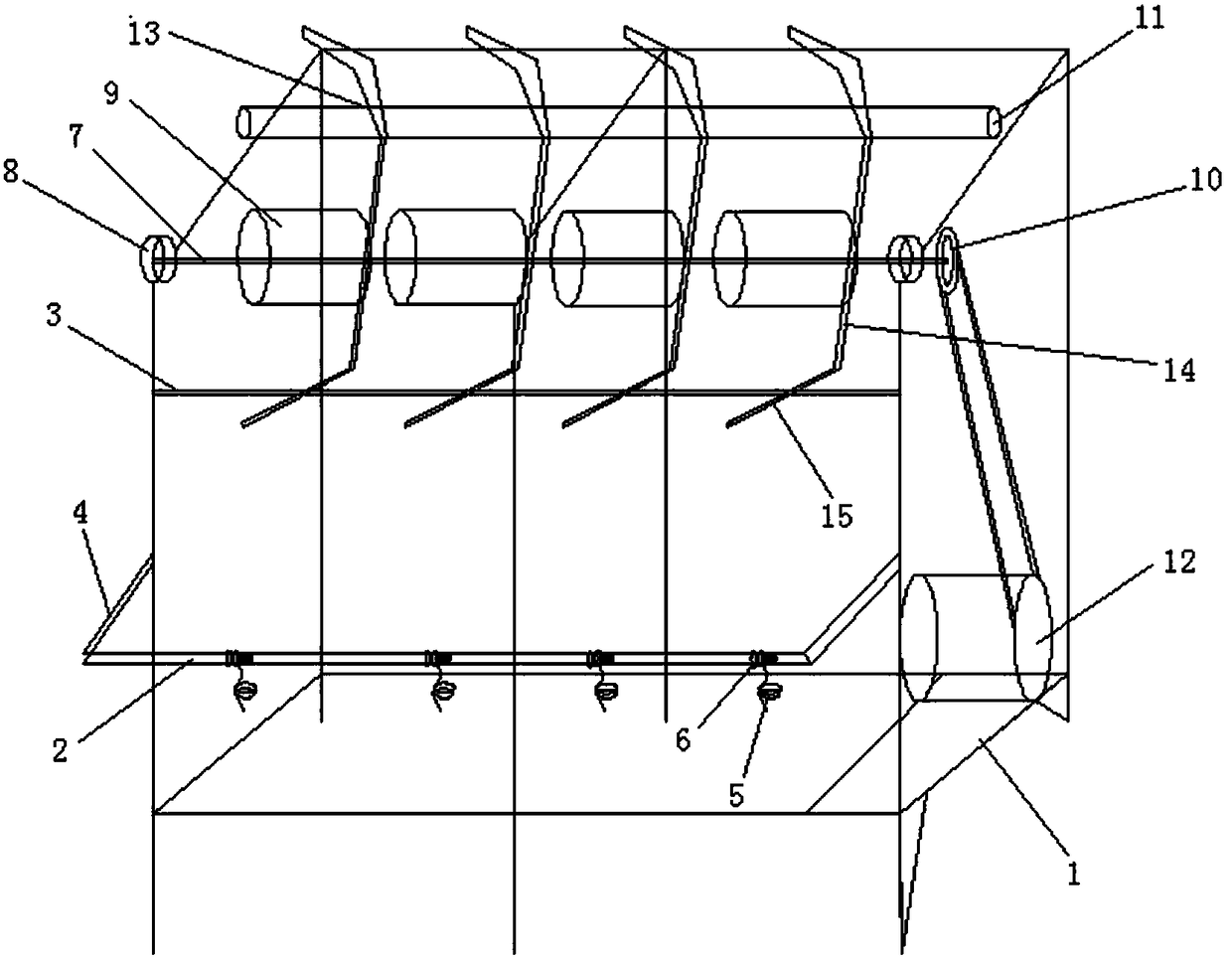

[0024] Such as figure 1 As shown, a household simple winder includes a frame part, a yarn guide part, a pressurized winding part, a broken end stop part and a transmission part.

[0025] 1. Rack part

[0026] The frame part is composed of 35*35 angle irons, the frame width is 38-40cm, the frame height is 88-95cm, every 80-85cm is a section, and each winding machine has 2-3 sections. The structure diagram of the rack part is as follows: figure 1 shown.

[0027] The frame part includes a motor seat 1, a yarn guide frame 2, a stop bar 3 and a fixed rod 4, and the yarn guide frame 2 is fixedly installed at a height of 45-50 cm from the ground, and the motor is fixedly installed at a distance of 68 cm from the top of the frame. Seat 1 is fixedly installed with stop bar 3 at 20-22cm from the top of the frame.

[0028] Rack length: 3 tanks can be installed in one section of the rack, and the number of sections can be configured according to the needs. Generally, 2-3 sections are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com