Skid-mounted small and medium-sized light hydrocarbon extraction system by using secondary refrigeration of vortex tube

The technology of extraction system and vortex tube is applied in the system field of vortex tube refrigeration and extraction of light hydrocarbons, which can solve the problems of equipment investment and operation cost increase, and achieve the effects of low manufacturing cost, convenient maintenance, and reduction of investment and operation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

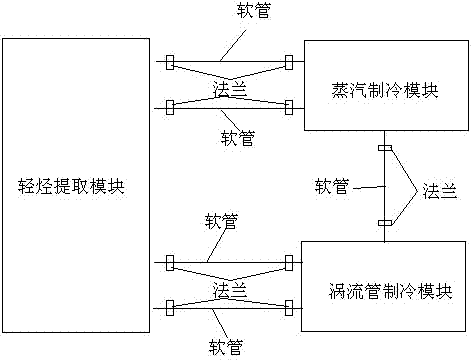

[0064] Considering the limited and scattered reserves of gas wells and oil wells, the devices configured in this system (between the light hydrocarbon extraction module, the steam refrigeration cycle module and the vortex tube refrigeration module) are connected by hoses and flanges, (see figure 2 shown) for easy installation and removal.

[0065] All adopt skid-mounted design.

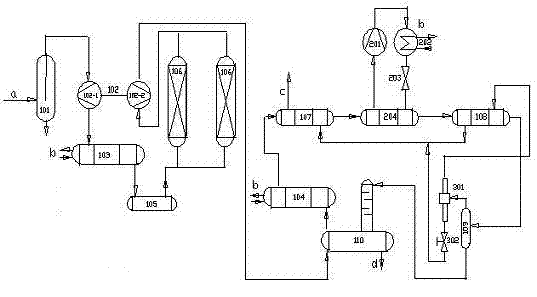

[0066] see figure 1 As shown, the raw material gas enters the light hydrocarbon extraction device at normal temperature and low pressure, and first enters the imported centrifugal separator 101 to separate oil, water and mechanical impurities. The purified raw gas enters the primary compression section 102- of the raw gas compressor 102 1. One-stage compression is carried out, and the boosted raw material gas is cooled to below 40°C by the first cooler 103, and then the liquid phase is removed by the liquid separation tank 105, and then enters the drying tower 106 for deep dehydration to below 10PPm...

Embodiment 2

[0069] The difference from Example 1 is that when the feed gas contains sulfur components, the feed gas first enters the dry desulfurizer for desulfurization and then enters the inlet centrifugal separator, and the dry gas at the hot end of the vortex tube is used as the regeneration gas source for the dry desulfurizer.

Embodiment 3

[0071] The difference from Example 1 is: when the raw gas source is unstable, a raw gas stabilized pressure storage tank is added before the inlet centrifugal separator.

[0072] According to the present invention, according to the natural conditions of the device implementation occasion, the coolant used for some cooling devices of the system can be selected from air, water and natural gas with considerable cooling capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com