Full-automatic multifunctional carding machine and tea processing method

A multi-functional and fully automatic technology, applied in the direction of tea processing before extraction, can solve the problems of high equipment input cost, large production site, lack of input production site, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

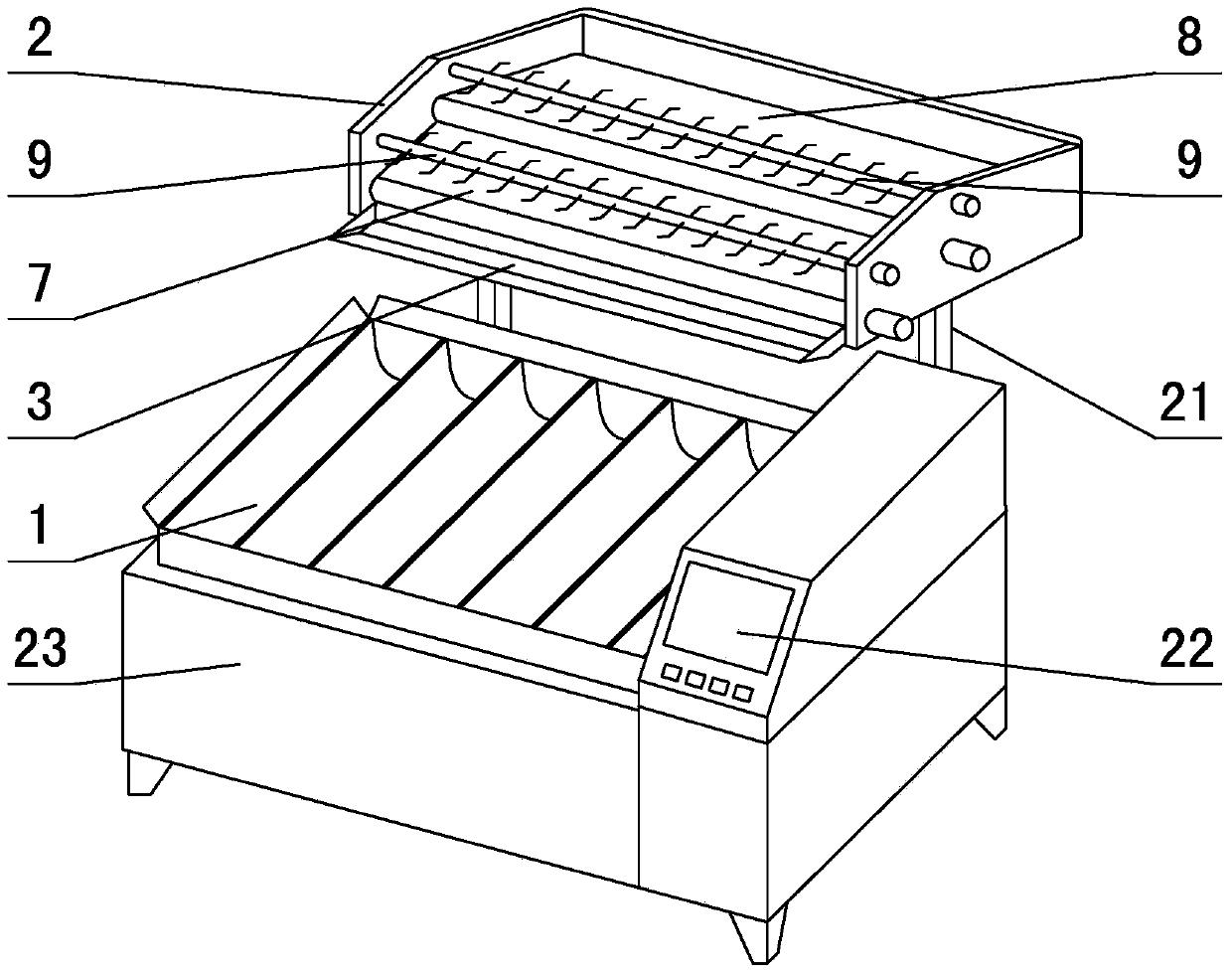

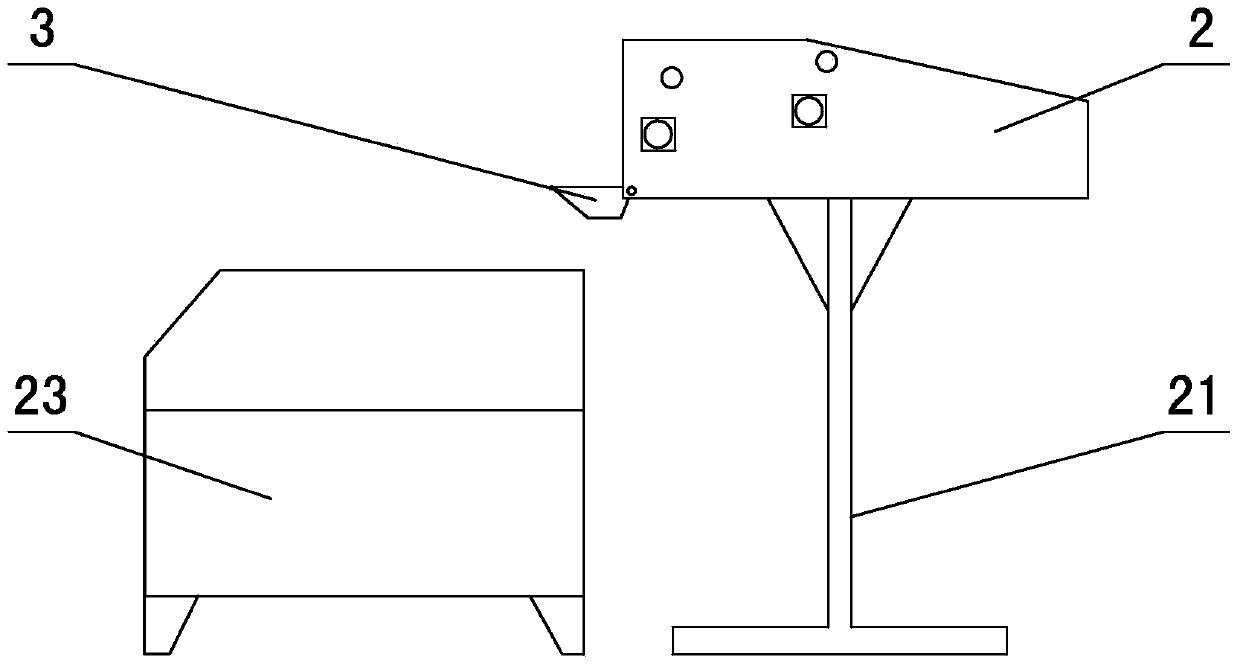

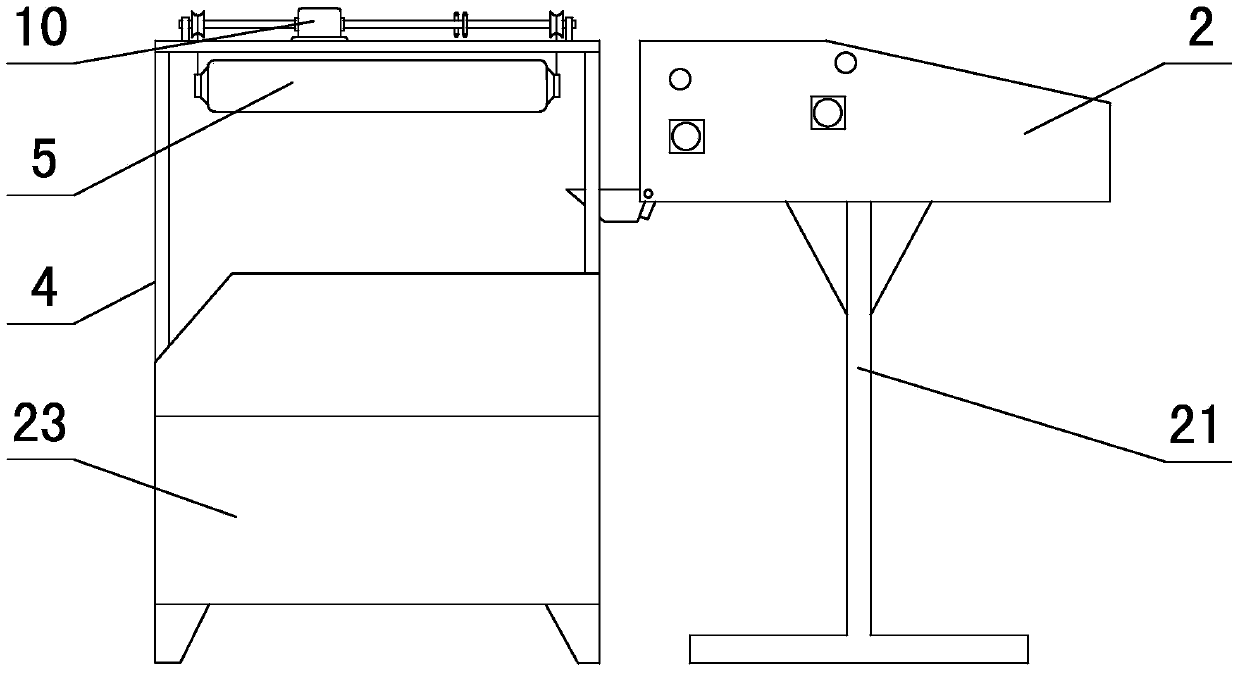

[0036] in such as figure 1 figure 2 In the shown embodiment 1, a kind of fully automatic multi-functional slitting machine comprises a main body and a swing-type pot arranged on the main body and a pot jacking device arranged under the pot (not shown in the figure). ), a controllable heating device (not shown in the figure) is also provided under the pot, the cross section of the groove of the pot 1 is U-shaped, and the opening width of the U-shaped groove is 120 to 180 mm. The present embodiment is 150 millimeters, and the U-shaped groove depth is 1.2 to 1.5 times of the opening width groove, and the present embodiment is 1.35 times. One side of the main body 23 is provided with a tea feeding table 2, the tea feeding table is arranged on the rear side of the main body through a bracket 21, the tea feeding table is provided with a tea delivery mechanism, and the tea delivery mechanism includes a The two tea conveyor belts on the top, the front tea conveyor belt 7 close to t...

Embodiment 2

[0046] An electrode plate 15 is respectively provided on the lower side of both ends of the crosspiece in embodiment 2 (see Figure 5 ), the lower end surface of the electrode plate is arc-shaped, and several conductive contacts 20 protruding from the arc-shaped surface are provided on the arc-shaped surface. The pressure roller includes a cylindrical cotton cloth jacket and steel balls 16 filled in the cotton cloth jacket (See Figure 9 ), the axial center of the pressure roller is equipped with an electric heating rod 17, and the two ends of the electric heating rod extend out of the cotton cloth jacket to form an extension shaft. The extension shaft is provided with a power supply ring 18, and the outer end of the extension shaft is provided with a movable collar 19 , the movable collar is fixed with the flexible connecting rope, when the pressure roller is raised, the power supply rings at both ends of the pressure roller abut against the electrode plates at both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com