System and method for indirectly thermo-chemically converting biomass slurry by using solar energy

A technology of thermochemical conversion and solar heat collector, applied in biochemical equipment and methods, biomass post-treatment, microbial dissolution, etc., can solve problems such as blocked pipelines, uneven heating, easy coking, etc., and achieve energy saving , low cost, and the effect of reducing energy input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

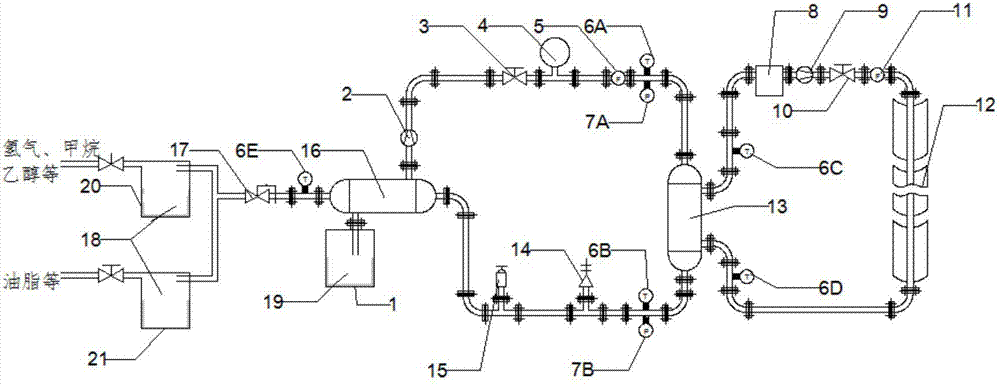

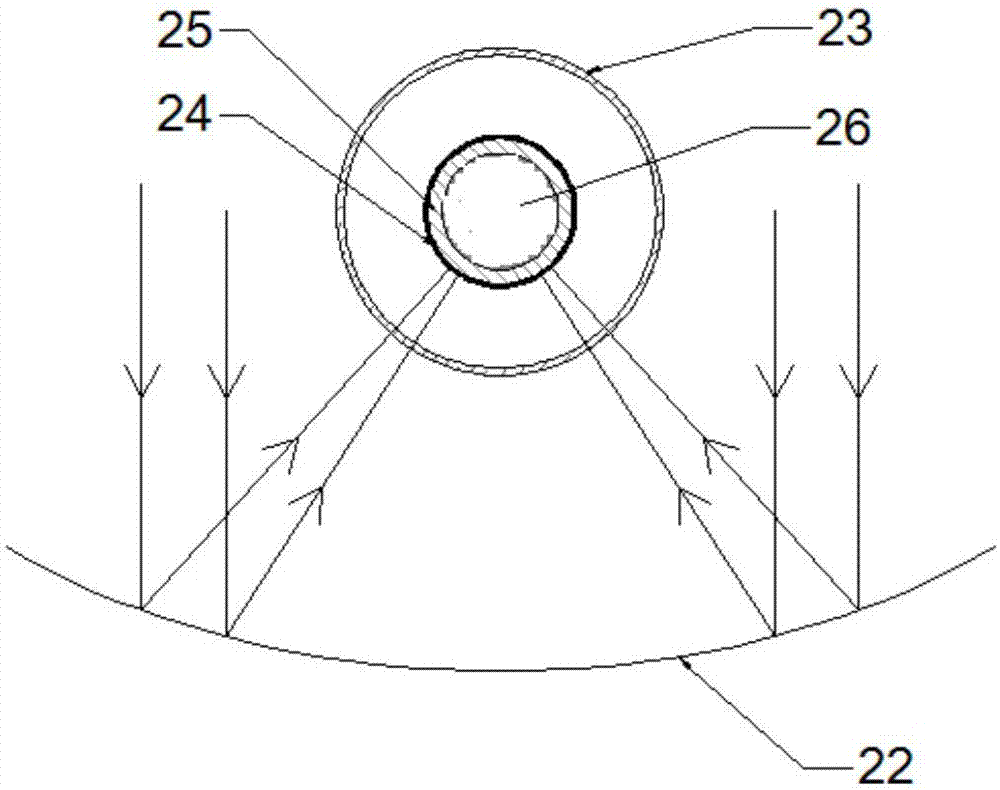

[0033] See Figure 1 to Figure 2 , A system for indirect thermal chemical conversion of biomass slurry using solar energy, including storage tank 1, plunger pump 2, regulating valve 3, damper 4, flow meter 5, temperature sensor, pressure sensor, heat conduction oil tank 8, heat conduction Oil pump 9, heat transfer oil regulating valve 10, heat transfer oil flow meter 11, solar collector 12, heat exchanger 13, safety valve 14, exhaust valve 15, waste heat recovery heat exchanger 16, back pressure valve 17, and fermentation device 20 And / or grease extraction device 21; where:

[0034] The algae cell suspension 19 is installed in the storage tank 1; the storage tank 1 is connected to the first inlet of the waste heat recovery heat exchanger 16 through a pipeline, and the first outlet of the waste heat recovery heat exchanger 16 passes through the plunger pump 2 and the pipe Road two is connected to the first inlet of the heat exchanger 13, the first outlet of the heat exchanger 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com