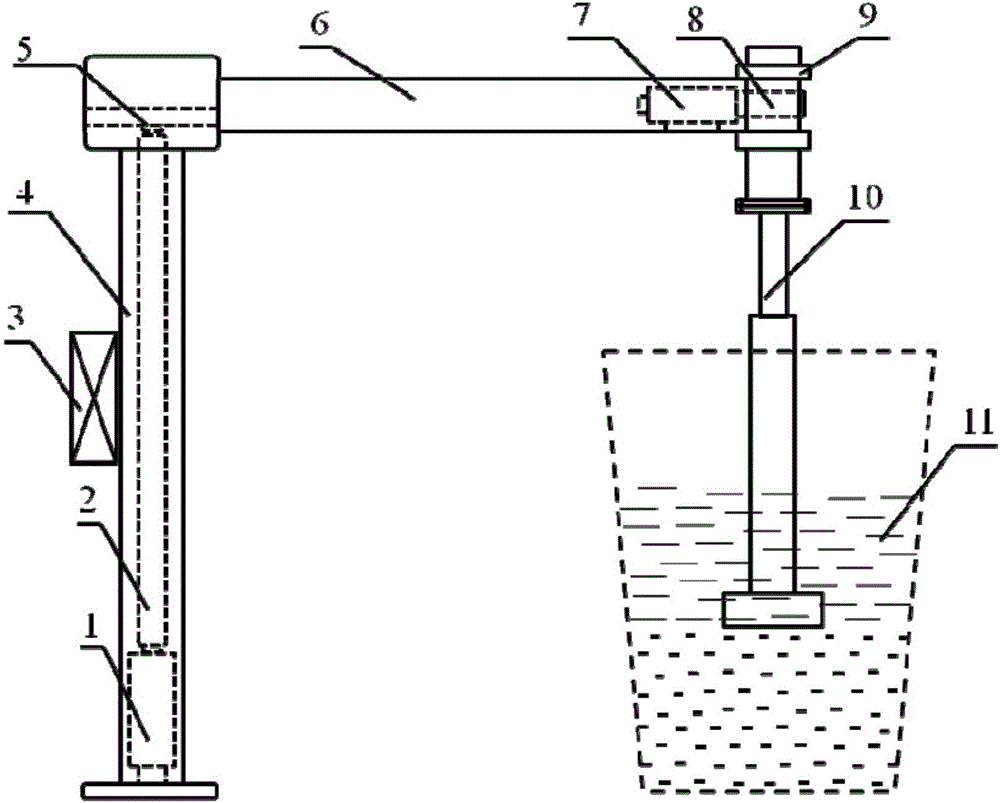

Mechanical stirring device for production of manganese-iron alloy

A technology of mechanical stirring and ferromanganese alloy, which is applied in mixers with rotating stirring devices, mixers, transportation and packaging, etc., can solve the problems of large power consumption, long pure processing time, large equipment volume, etc., and achieve operating costs Problem solving, compact and simple equipment, and simple equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this example, low-carbon ferromanganese is produced by double-connected electrosilicothermal method and mechanical stirring method. The process route implemented by the mechanical stirring method is as follows: Manganese slag discharge from the electric furnace → driving and lifting the shaker to the transport vehicle → driving to the stirring station → adding ferrosilicon material → determining the liquid level → taking slag samples → lowering the paddle to stir the manganese liquid and Slag liquid reaction→taking slag samples→extracting from the mixing station→lifting to the slag dumping station for dumping→lifting to the ingot pouring platform→manganese liquid ingot casting.

[0023] The inner height of the ferromanganese treatment tank is 1700mm, and the mouth diameter is 1600mm. After the manganese liquid is discharged from the medium manganese electric furnace, slowly and uniformly pour 4.5t of liquid medium manganese slag into the manganese slag treatment tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com