Method and device for co-production of coal, fuel gas and tar

A technology of coal and gas, which is applied in the field of co-production of coal, gas and tar and its devices, can solve the problems of environmental pollution, relying on natural formation, long-term human beings, etc., to solve the problem of low biogas gas, keep the environment clean, solve Invest in big effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments.

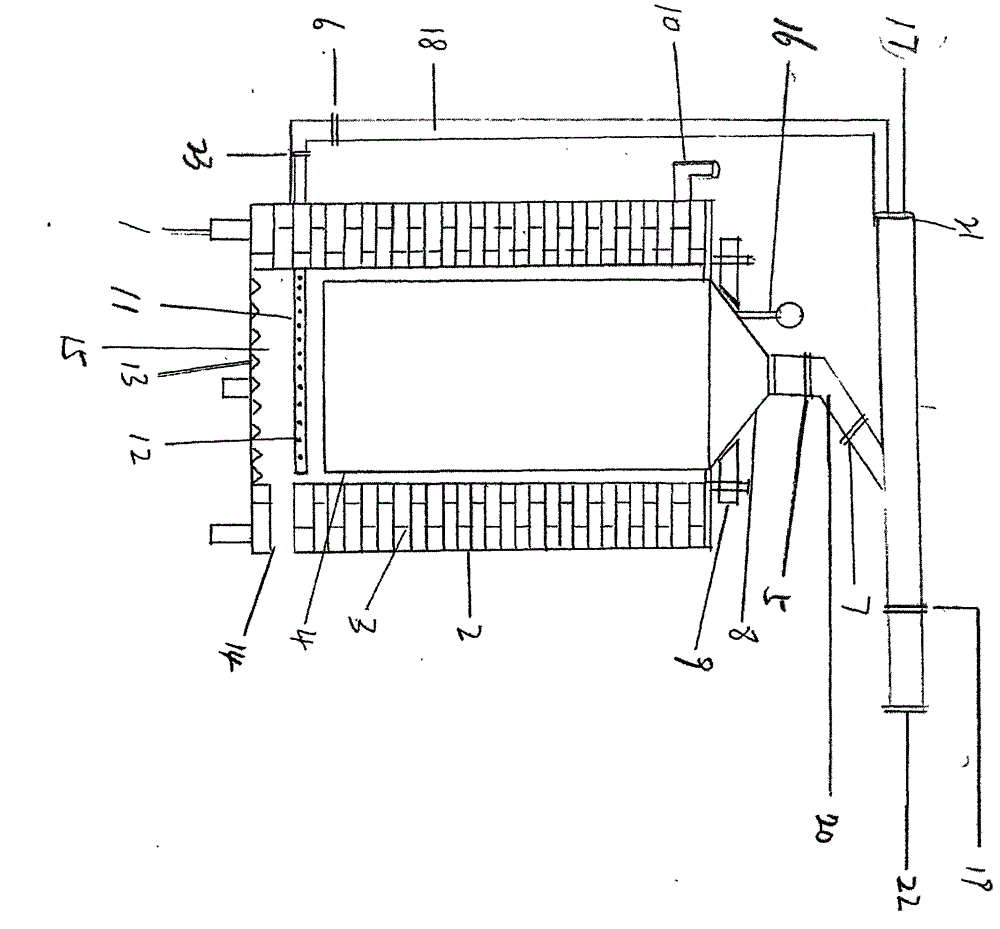

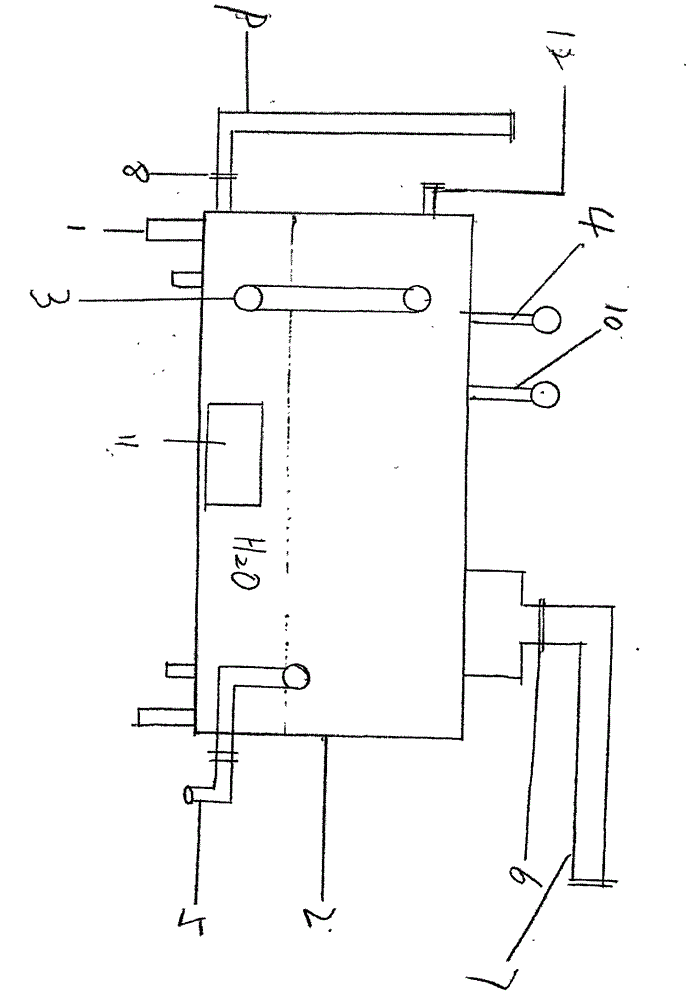

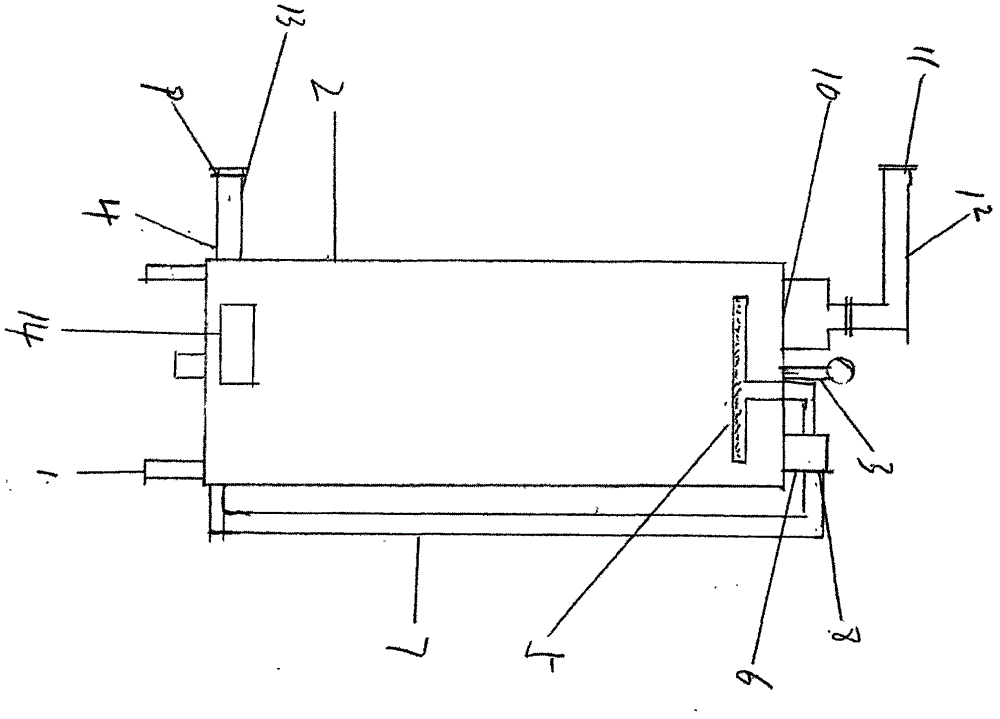

[0018] in figure 1 Among them, the support column (three pillars as triangular support) 1 supports the outer tank 2, and the outer tank 2 is surrounded by refractory bricks 3, and the outer tank and refractory bricks are made into a furnace for heating the inner tank 4. After adding combustibles to the inner tank 4, put it into the outer tank 2, cover the inner tank cover 8, and fix it with lock blocks 9 (three in total). By starting a fire in the furnace and closing the fire door 14, the inner bladder 4 is directly burned to increase the temperature in the inner bladder 4. As the temperature and pressure increase, the combustibles will fission and form gas. The principle of the law naturally enters the pipe 20 and is transported to the main pipe 17, the gas is divided to the left and right, enters the combustion pipe 11 through the return pipe 18, and enters the combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com