Heat treatment method for regulating and controlling microstructure and microhardness of near-beta titanium alloy

A heat treatment method and microstructure technology, applied in the field of titanium alloy processing, to achieve the effects of improving mechanical properties and functional properties, improving stability, and improving alloy performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] After the Ti-7333 alloy after billet forging was subjected to solid solution treatment at 900°C / 30min (the temperature of the heat treatment furnace was 900°C, and the holding time was 30min), a sample was formed. The microstructure of the sample was as follows: figure 1 , where the tissue feature is full-β tissue with isometric tissue features.

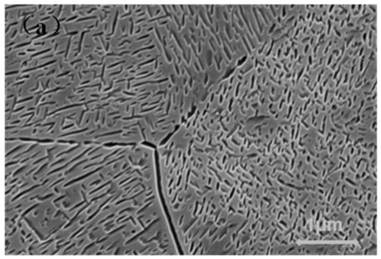

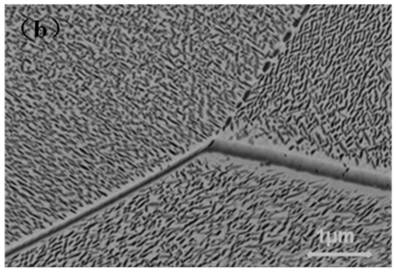

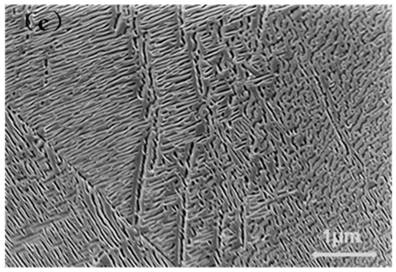

[0047] Then the sample is raised from room temperature to 700°C at a heating rate of 5°C / min, and different elastic tensile stresses are applied to the sample. At this time, the microstructure of the sample is as follows: Figure 2-4 shown, where figure 2 is the microstructure characteristics of the sample (Ti-7333 alloy) in the unstressed state, image 3 is the microstructure characteristics of the sample (Ti-7333 alloy) under the state of 20MPa tensile stress, Figure 4 It is the microstructure characteristics of the sample (Ti-7333 alloy) under the state of 20MPa compressive stress.

[0048] No elastic stress is applied...

Embodiment 2

[0050] After the Ti-7333 alloy that has been forged by blanking is subjected to solution treatment at 900°C / 30min (the temperature of the heat treatment furnace is 900°C, and the holding time is 30min), the sample is formed, and then the sample is heated at a heating rate of 10°C / min. Raise to 700°C, and apply different elastic tensile stresses to the sample; among them, such as Figure 5 Shown is the microstructure characteristics of the sample (Ti-7333 alloy) under no stress; as Image 6 Shown is the microstructure characteristics of the sample (Ti-7333 alloy) under the action of 20MPa compressive stress; as Figure 7 Shown is the microstructure characteristics of the sample (Ti-7333 alloy) under the action of 50MPa compressive stress.

[0051] like Figure 5 The grain size of the short rod-shaped α phase precipitated in the stress-free state is about 218-425 μm; Image 6 As shown, under the action of 20MPa compressive stress, in the direction parallel to the applied stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com