Bending equipment

A technology of equipment and bending arms, applied in heat exchange equipment, metal processing equipment, feeding devices, etc., can solve the problems of reducing product yield, easy damage of flat tubes, and straining the surface of heat exchangers, and reduce constraints. , The effect of improving the yield rate and reducing the probability of strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

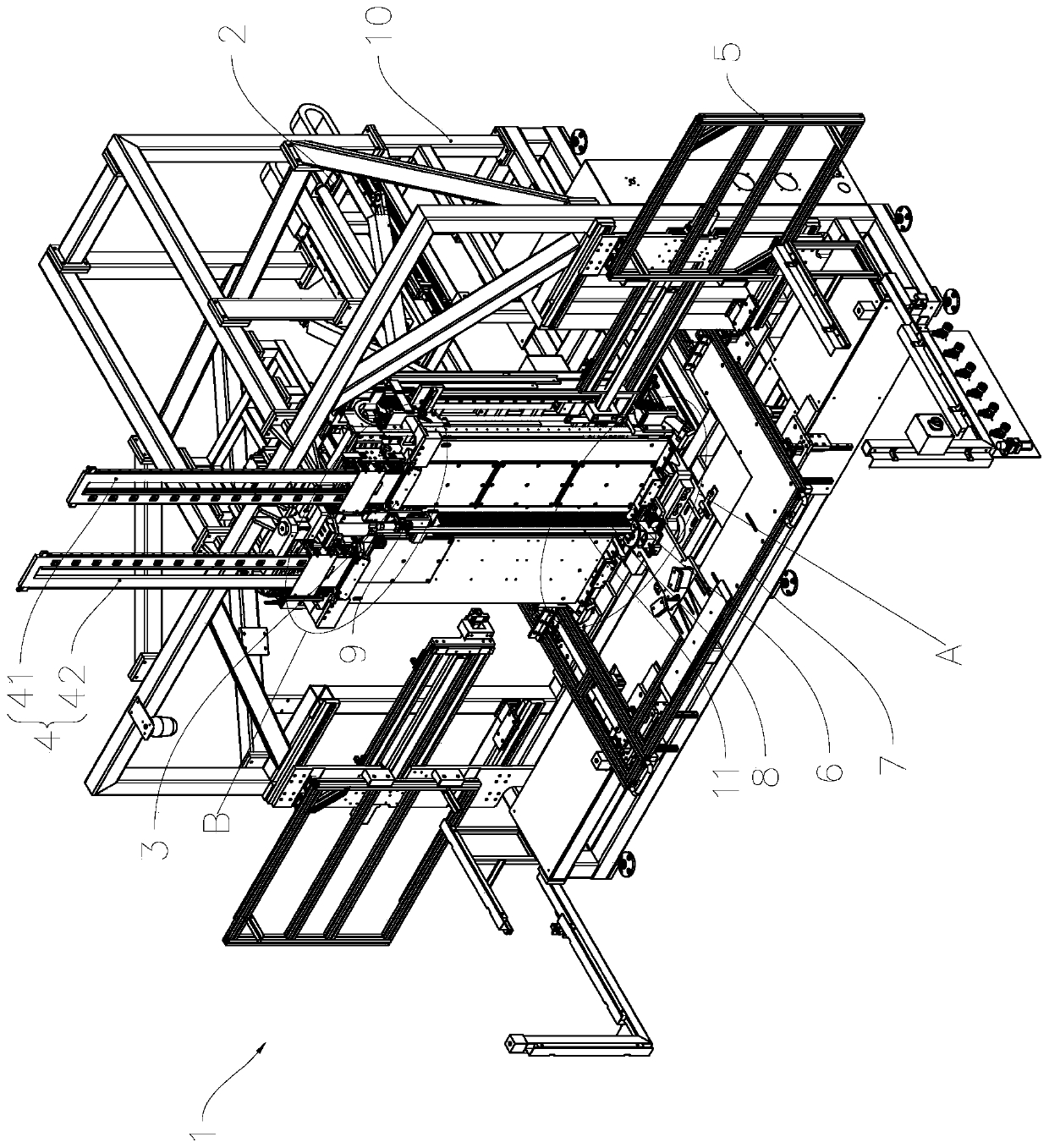

[0043] see figure 1 , the bending equipment 1 of the present invention includes a frame 10, a control unit and a bending unit 2 installed on the frame 10, a clamping unit 3, a centering unit 5, a mandrel unit 11, a pick unit 6, and a feeding unit 7. Plug unit 8 and pressing protrusion unit 9 .

[0044] The control unit is not shown in the drawings, and it includes a processor, a memory, and a control touch screen installed on the foundation or frame. The processor receives instructions input by the operator through the control touch screen, and executes the corresponding computer program in the memory according to the instructions. Each unit in the control bending equipment 1 cooperates to perform operations such as centering, inserting, picking, pulling out, and bending the workpiece.

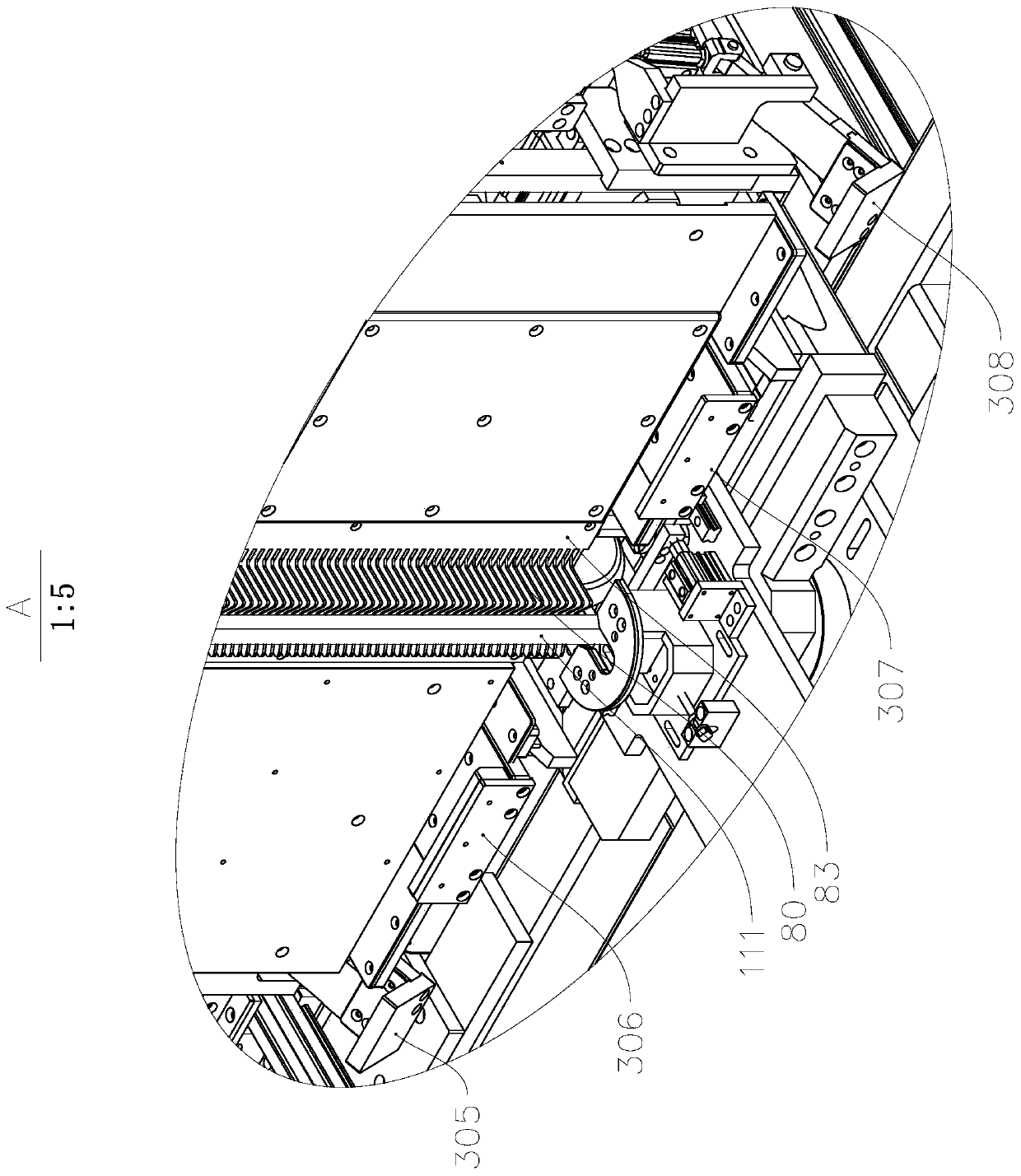

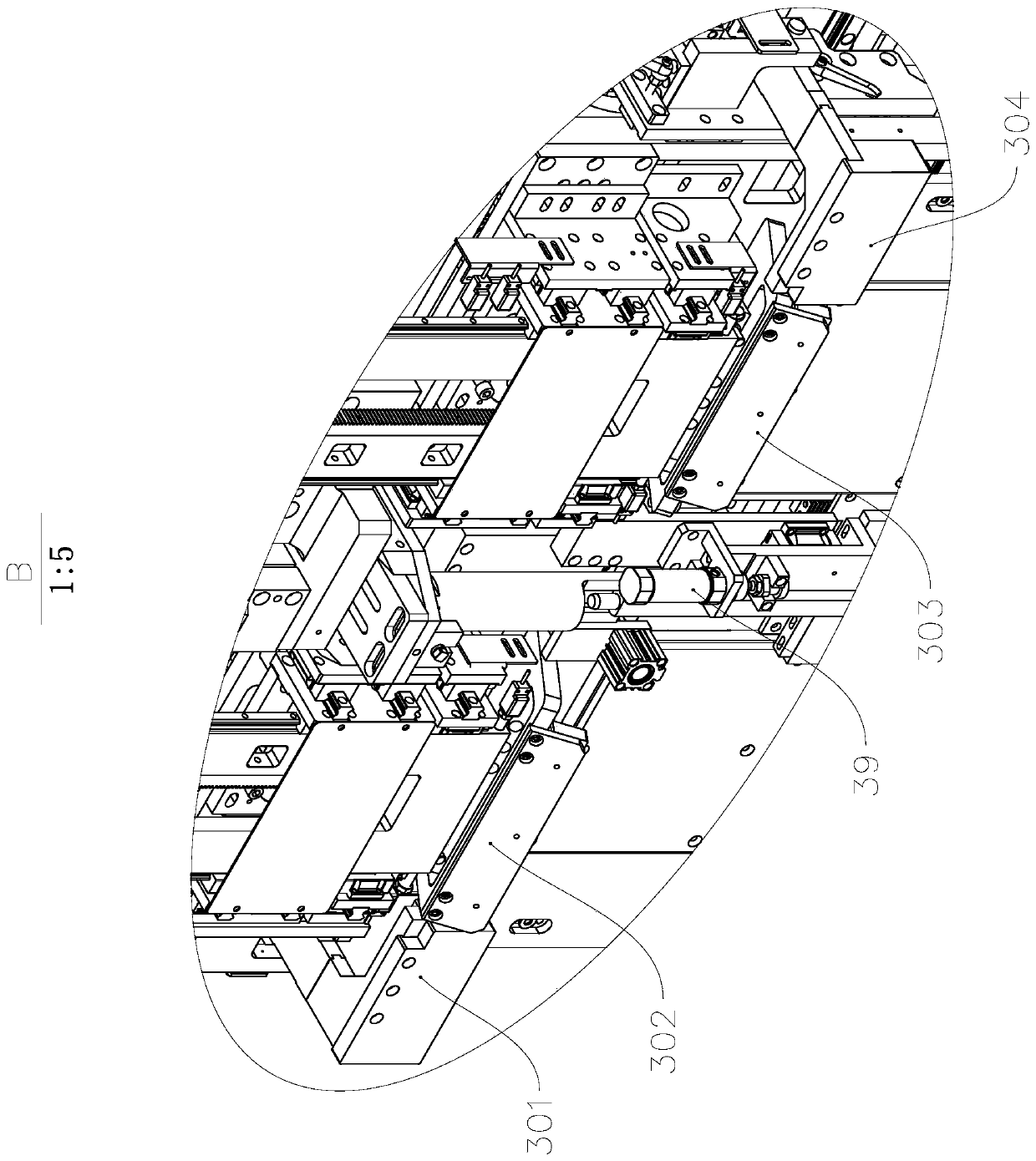

[0045] see Figure 1 to Figure 4 , the bending unit 2 includes a bending servo motor 20, a bending screw 21, a driven nut, a bending slide 22, a left bending linear guide 231, a right bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com