Electric pulse aftertreatment method and device for improving performance of metal component

A post-processing device and metal component technology, which is applied in the field of metal post-heat treatment, can solve the problems of long time consumption, large equipment footprint, cumbersome process and process, etc., and achieve the effects of increasing the size range, uniform heating, and wide quenching surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

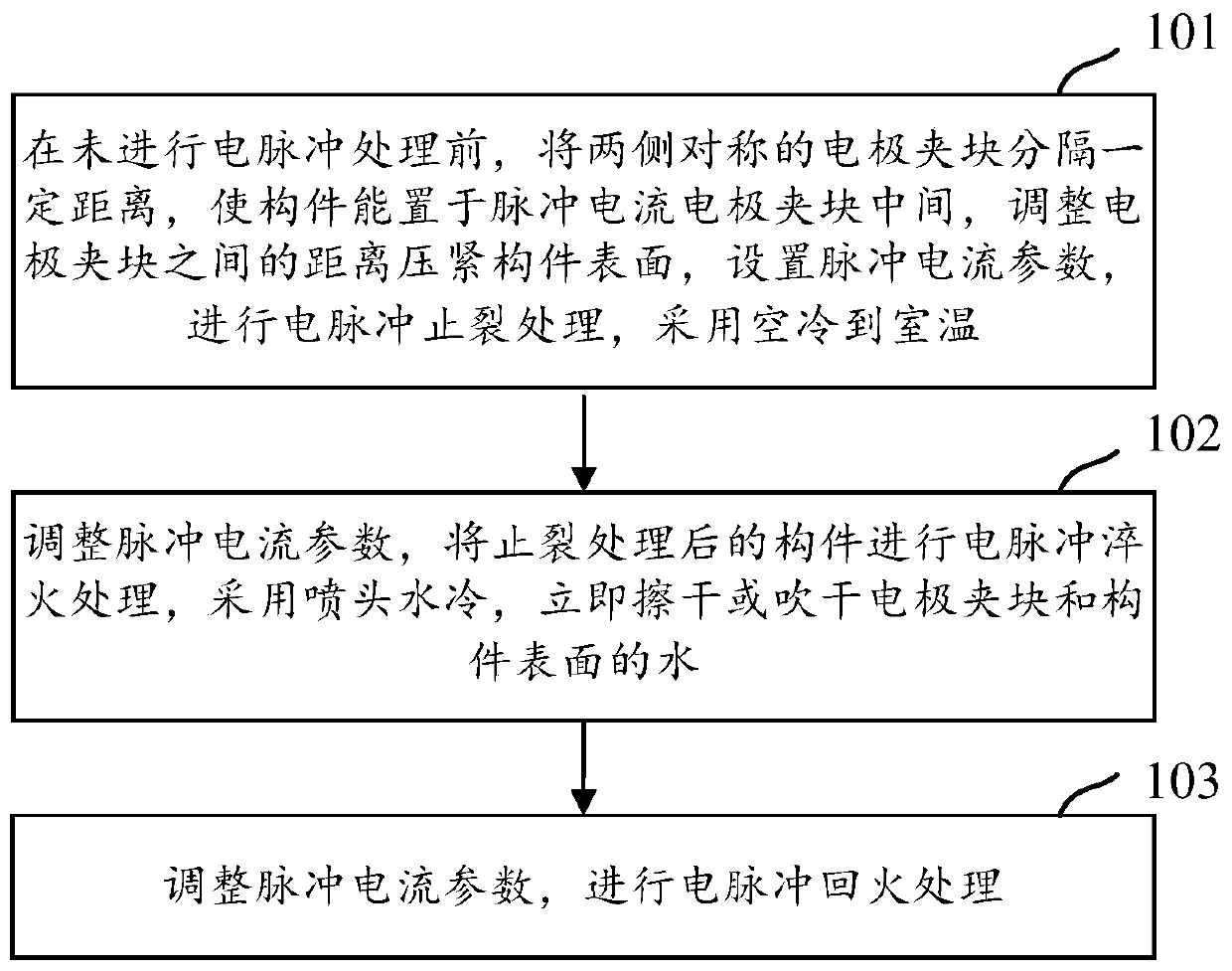

Method used

Image

Examples

Embodiment 1

[0053] The laser additive manufacturing component used in this example is a high-speed rail brake disc with a diameter of 640 mm and a height of 80 mm. Its composition is 24CrNiMo alloy steel. The main chemical composition is shown in Table 1. The forming method is that the disc surface is perpendicular to the substrate.

[0054] Table 1 Analysis of chemical composition of 24CrNiMo alloy steel

[0055]

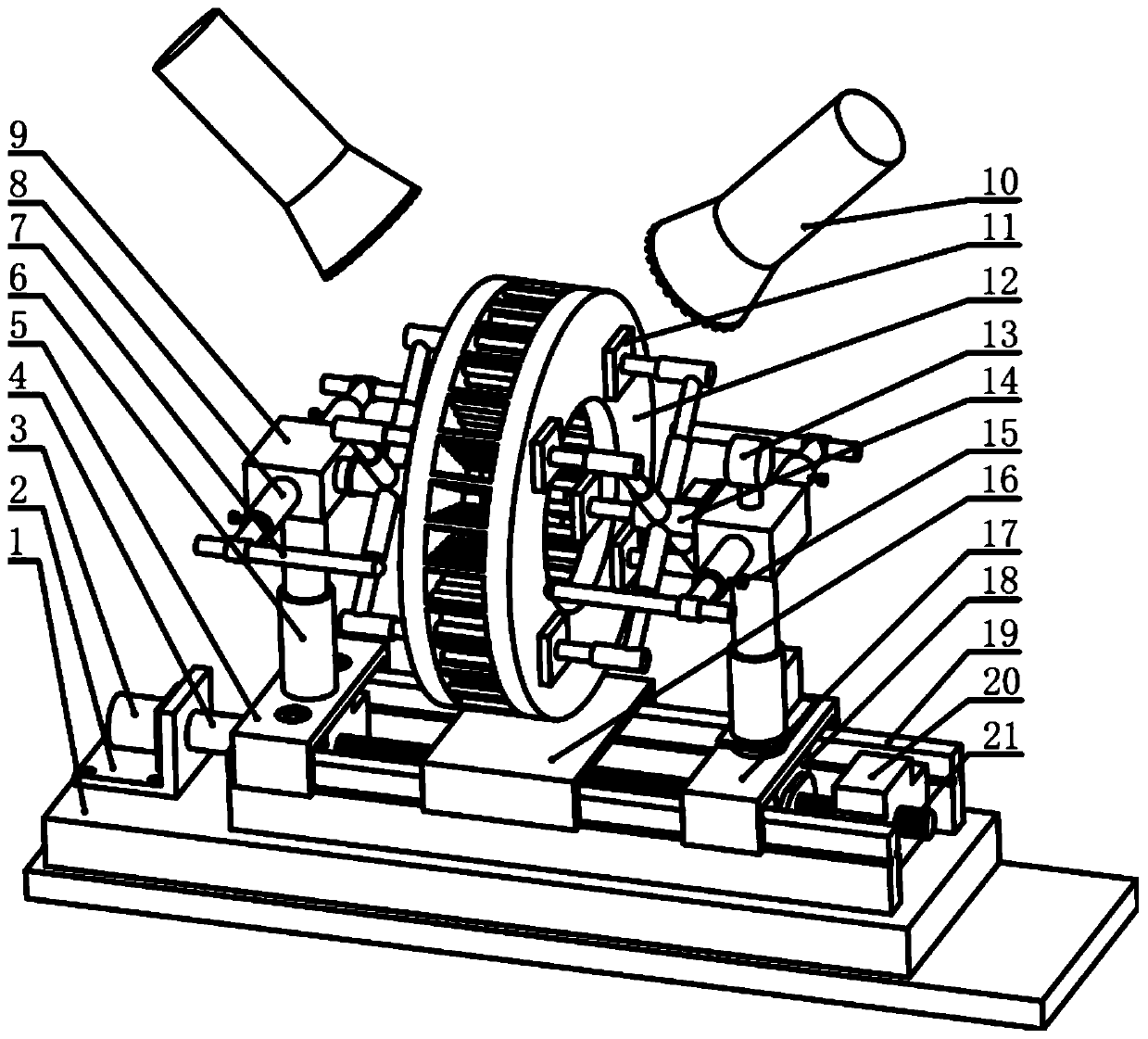

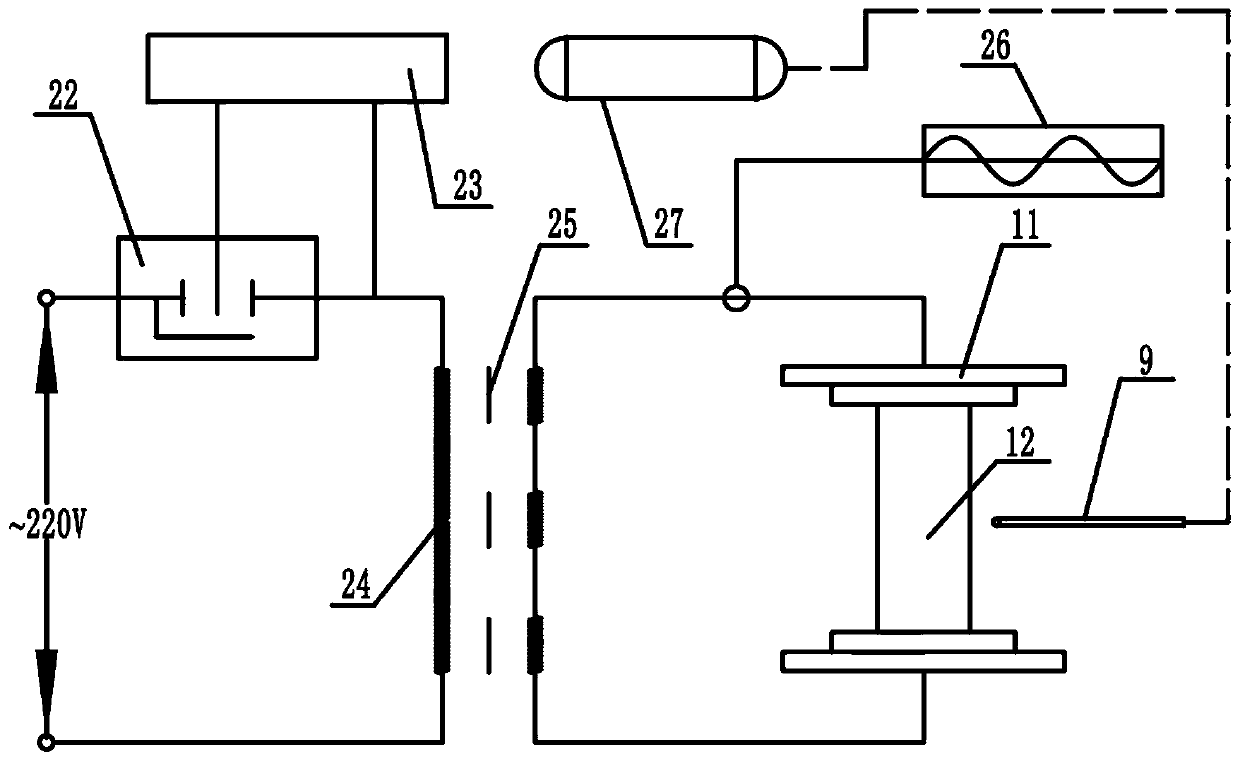

[0056] Grind the surface of the high-speed rail brake disc 12 with the above composition to be smooth, start the electric pulse device, adjust the distance between the electrode clamping blocks 11 of the pulse current device through the overall PLC automatic control system to be greater than 80mm, and place the brake disc 12 with a manipulator. On the support slider 16, adjust the diagonal distance of the electrode clamping blocks 11 in a square distribution to 550mm, adjust the horizontal distance of the electrode clamping blocks 11 so that the disk surfaces on both sides o...

Embodiment 2

[0058] The laser additive manufacturing component used in this example is a high-strength stud with a length of 85.88 mm and a diameter of 6.00 mm. Its composition is 35CrMo alloy steel. The main chemical composition is shown in Table 2. The forming method is that the stud is parallel to the substrate.

[0059] Table 2 Analysis of chemical composition of 35CrMo alloy steel

[0060]

[0061] Use 150#, 360# and 600# sandpaper to polish the end faces of the double-ended studs 12 of the above-mentioned composition successively, and use the same process steps as in Example 1 for post-treatment with electric pulses, wherein the double-ended studs 12 are two The side end face is placed in the middle of any electrode clamp 11, the distance between the electrode clamps 11 is adjusted to 6.00mm, the pressure is 0.001Mpa, the working voltage is 5V, the frequency is 50Hz, and the current density of the electric pulse crack arrest treatment is 30MA / m 2 , the electric pulse time is 360ms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com