Automatic insert manipulator for injection molding machine

A technology of injection molding machines and manipulators, applied in the direction of coating, etc., can solve problems such as high labor intensity, hidden dangers of physical safety, pinch injuries of injection molding machines, etc., and achieve the effect of ensuring personal safety and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

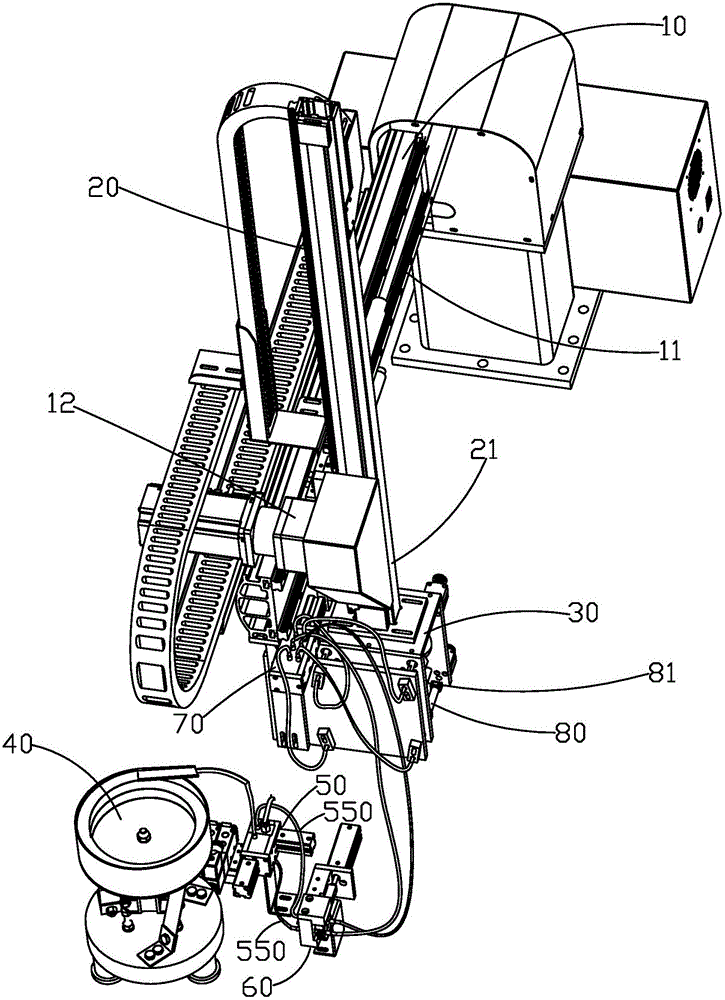

[0029] refer to figure 1 , an automatic insert manipulator for an injection molding machine, comprising a frame 10, a horizontal guide rail 11 is arranged on the frame 10, a horizontal moving platform 12 is movably arranged on the horizontal guiding rail 11, and the horizontal moving platform 12 is connected with Drive its horizontal drive mechanism to move back and forth along the horizontal guide rail 11. Here, the above-mentioned horizontal drive mechanism is an air cylinder or a hydraulic cylinder, and the air cylinder or hydraulic cylinder is fixedly arranged on the support 10, and the The piston rod is fixedly connected with the horizontal moving table 12. When the piston rod of the air cylinder or hydraulic cylinder stretches out or shrinks, it can drive the horizontal moving table 12 to move back and forth along the horizontal guide rail 11. Of course, the above-mentioned horizontal driving mechanism also Can adopt other structure to replace, comprise a motor and threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com