Fast injection molding system

An injection molding, fast technology, applied in the field of rapid injection molding system, can solve the problems of poor heating efficiency, prolonged cooling time, affecting cooling efficiency, etc., to achieve good cooling efficiency, improve efficiency, and shorten heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

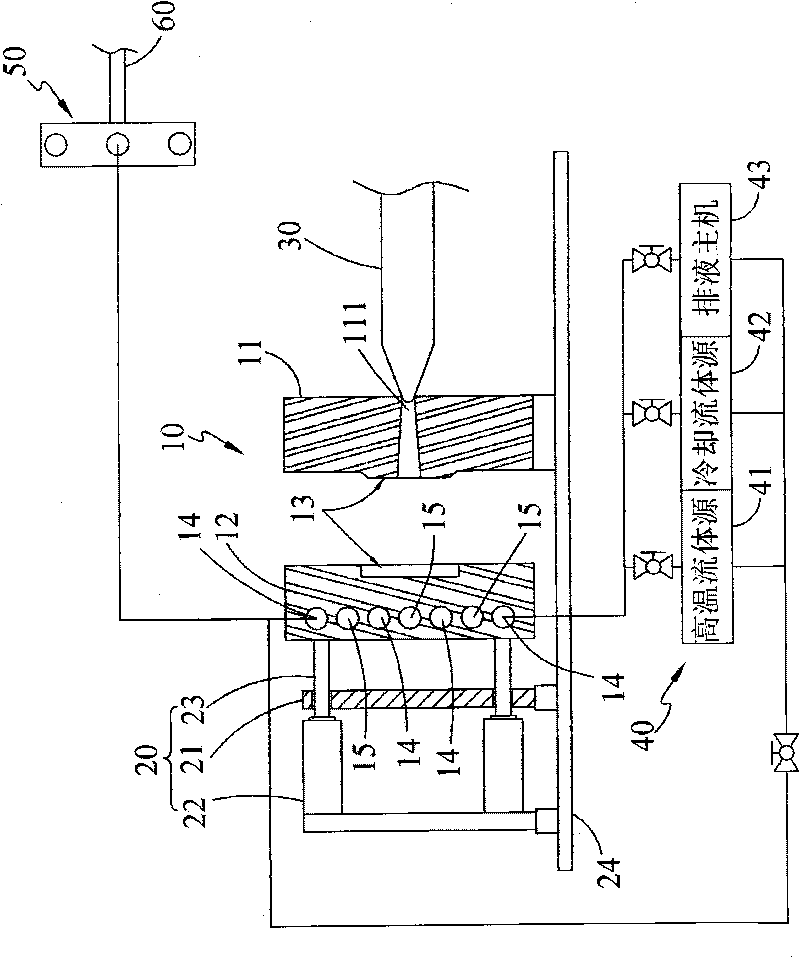

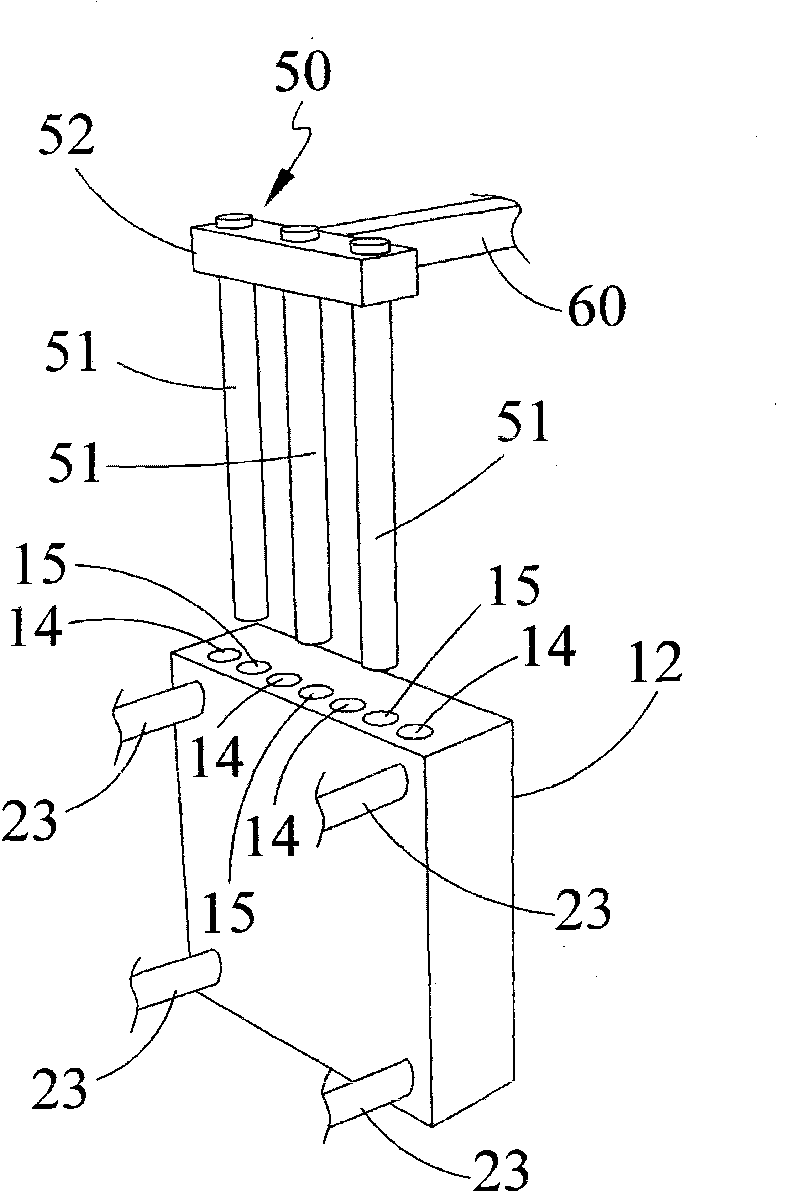

[0017] see figure 2 As shown, it is a rapid injection molding system disclosed in the first embodiment of the present invention, which is used to make an injection molded part, which includes a mold 10, a clamping device 20, an injection molding machine 30, and a temperature control device 40 , a heating element 50, and a moving device 60.

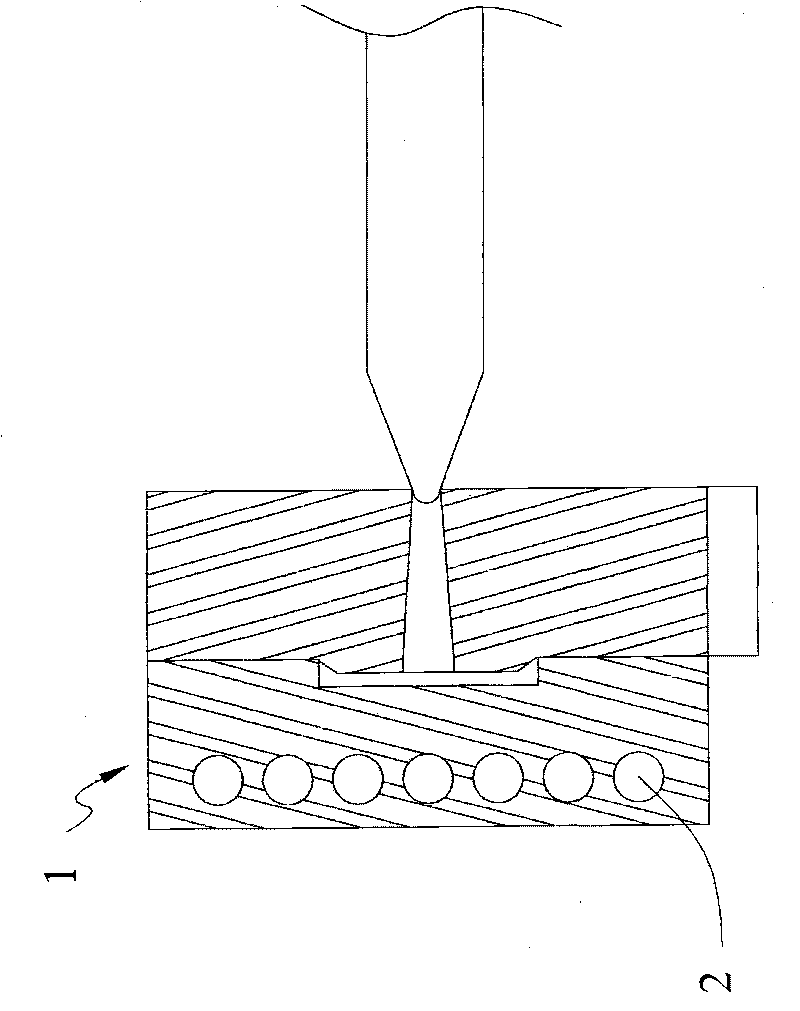

[0018] refer to figure 2 As shown, the mold 10 includes a male mold 11 and a female mold 12, the male mold 11 and the female mold 12 have corresponding protrusions or concave structures respectively, after the male mold 11 and the female mold 12 are combined with each other, the male mold 11 A hollow mold cavity 13 is formed between the female mold 12 and used for injecting molding liquid into it. After the injection molding liquid filling the mold cavity 13 is cooled and solidified, an injection molded part whose shape matches the mold cavity 13 is formed. The male mold 11 has a sprue 111 connected to the mold cavity 13 , and the inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com