Plastic pressure reducer and manufacturing method of plastic pressure reducer

A technology of pressure reducer and plastic, applied in the field of pressure reducer and its preparation, can solve the problems of troublesome processing technology, high production cost and heavy weight of the pressure reducer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

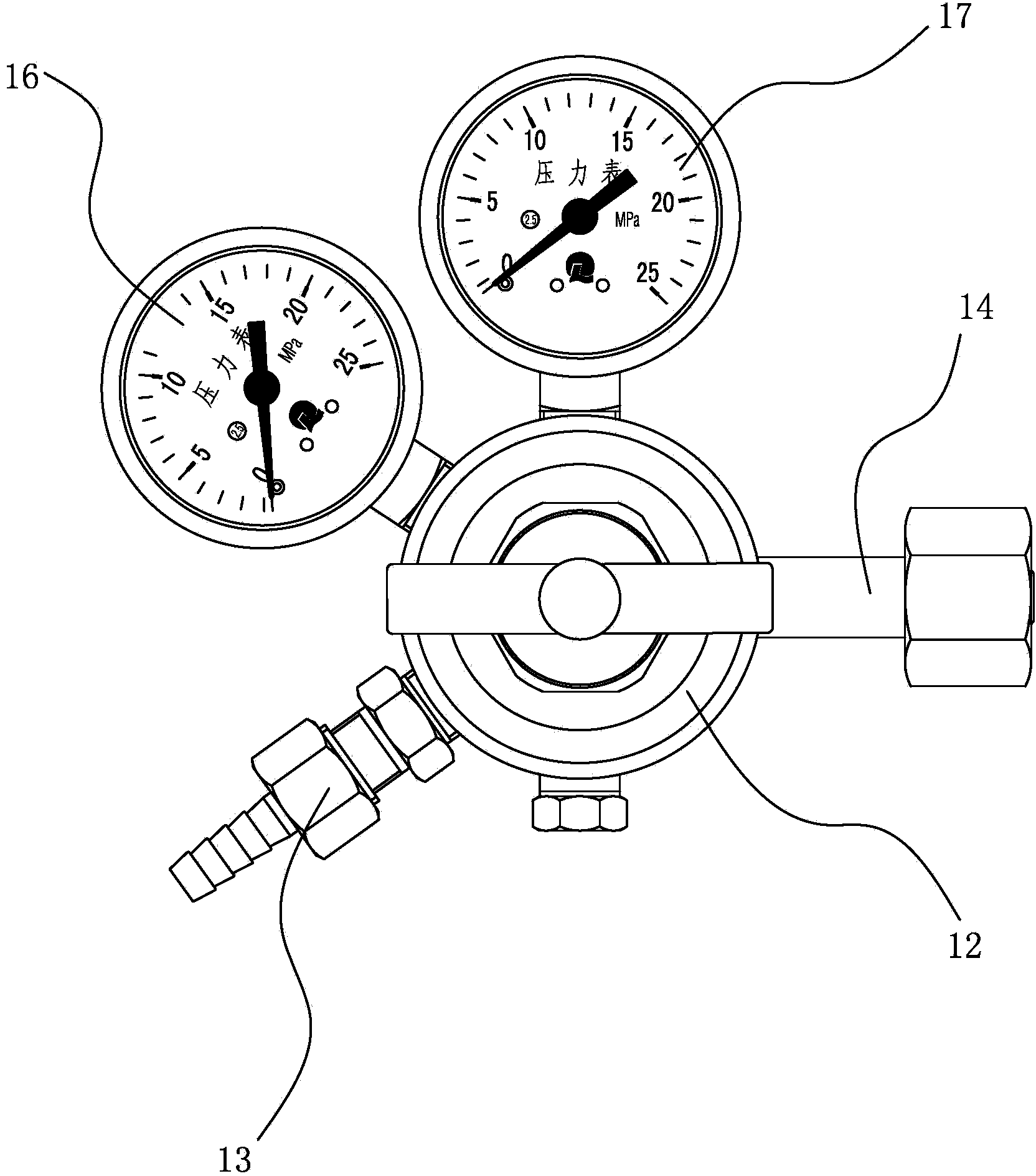

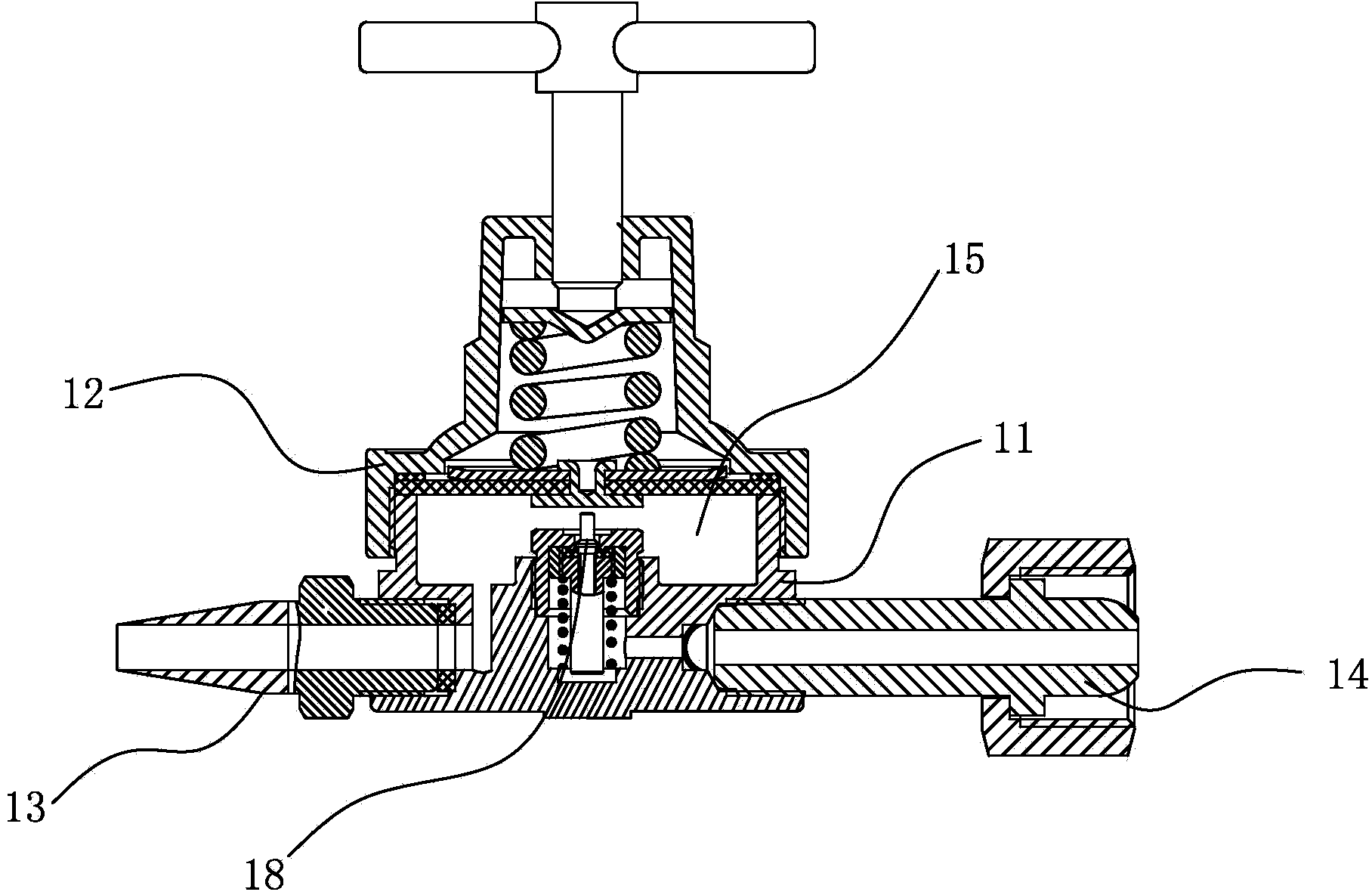

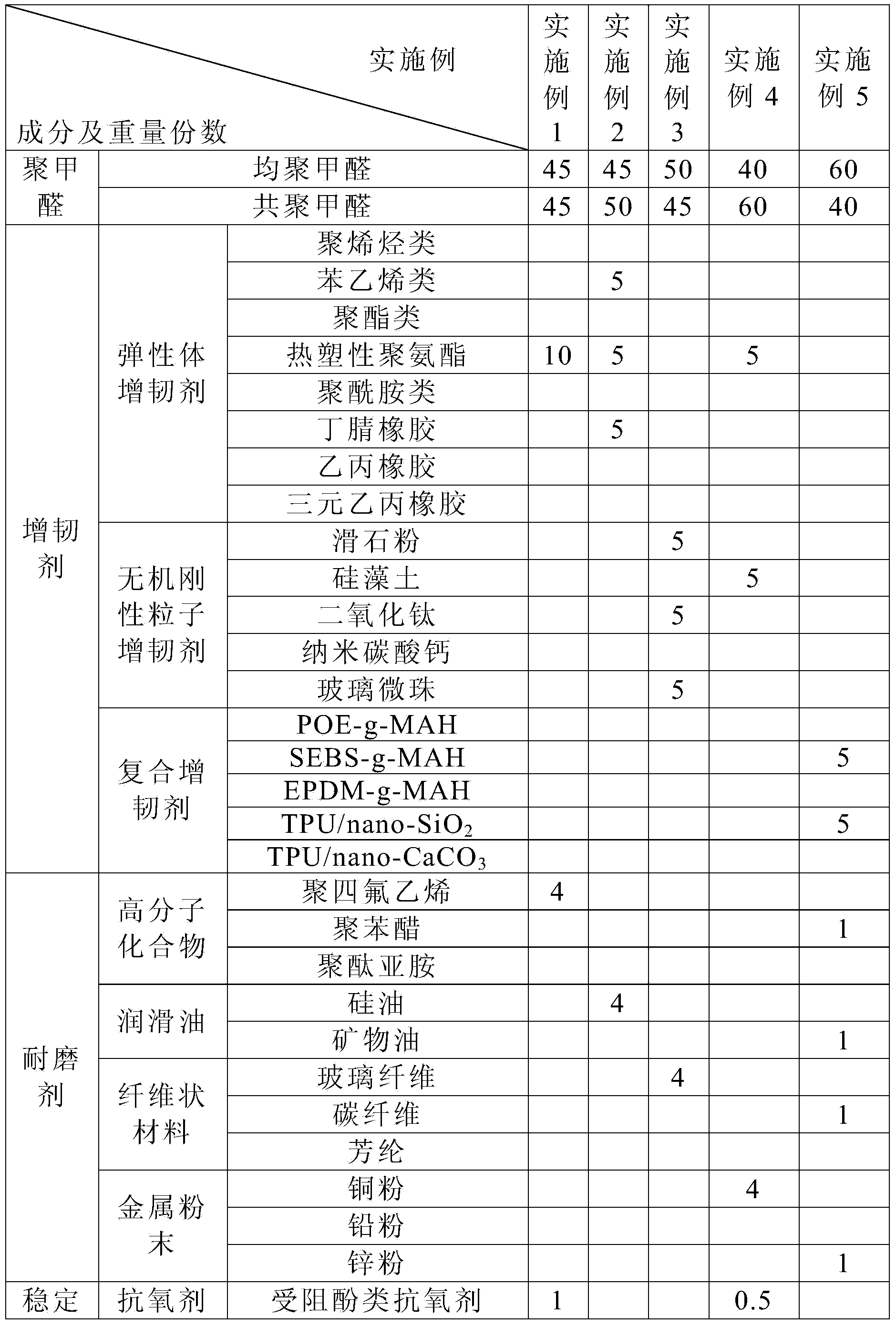

Embodiment 1

[0042] The raw materials were weighed according to the components and parts by weight of Example 1 in Table 1, and the polyoxymethylene was dried in an oven at a temperature of 70° C. for 2-4 hours. At the same time, heat the barrel in the high-speed injection molding machine to 185°C, and then weigh the toughening agent, wear-resistant agent, compatibilizer, flame retardant, antistatic agent, stabilizing modifier and polyoxymethylene after drying Mix well and add to the barrel, heat to molten state, and inject twice through the nozzle of the hot runner at 220°C into the shell and cover mold at 90°C, where the first injection pressure is 110MPa, The second injection pressure is 90 MPa. Then keep it under the pressure of 100MPa for 8S, then cool down for 35S, and open the mold to make the shell and cover. Finally, the prepared shell and cover are assembled with an air inlet pipe, an air outlet pipe, a throttle valve, a gas high pressure gauge, and a gas low pressure gauge to f...

Embodiment 2

[0044] The raw materials were weighed according to the components and parts by weight of Example 2 in Table 1, and the polyoxymethylene was dried in an oven at a temperature of 70° C. for 2-4 hours. At the same time, heat the barrel in the high-speed injection molding machine to 185°C, and then weigh the toughening agent, wear-resistant agent, compatibilizer, flame retardant, antistatic agent, stabilizing modifier and polyoxymethylene after drying Mix well and add to the barrel, heat to molten state, and inject twice through the nozzle of the hot runner at 220°C into the shell and cover mold at 90°C, where the first injection pressure is 110MPa, The second injection pressure is 90 MPa. Then keep it under the pressure of 100MPa for 8S, then cool down for 35S, and open the mold to make the shell and cover. Finally, the prepared shell and cover are assembled with an air inlet pipe, an air outlet pipe, a throttle valve, a gas high pressure gauge, and a gas low pressure gauge to f...

Embodiment 3

[0046] The raw materials were weighed according to the components and parts by weight of Example 3 in Table 1, and the polyoxymethylene was dried in an oven at a temperature of 70°C for 2-4 hours. At the same time, heat the barrel in the high-speed injection molding machine to 185°C, and then weigh the toughening agent, wear-resistant agent, compatibilizer, flame retardant, antistatic agent, stabilizing modifier and polyoxymethylene after drying Mix well and add to the barrel, heat to molten state, and inject twice through the nozzle of the hot runner at 220°C into the shell and cover mold at 90°C, where the first injection pressure is 110MPa, The second injection pressure is 90 MPa. Then keep it under the pressure of 100MPa for 8S, then cool down for 35S, and open the mold to make the shell and cover. Finally, the prepared shell and cover are assembled with an air inlet pipe, an air outlet pipe, a throttle valve, a gas high pressure gauge, and a gas low pressure gauge to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com