Double-color injection-molding die with active spacing block and preparation method thereof

A two-color injection molding and spacer technology, applied in the field of two-color injection molds, can solve the problems of complicated mold development, reduced injection efficiency, and large investment amount, so as to achieve the effect of uncomplicated mold structure, improved injection molding efficiency, and small investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments.

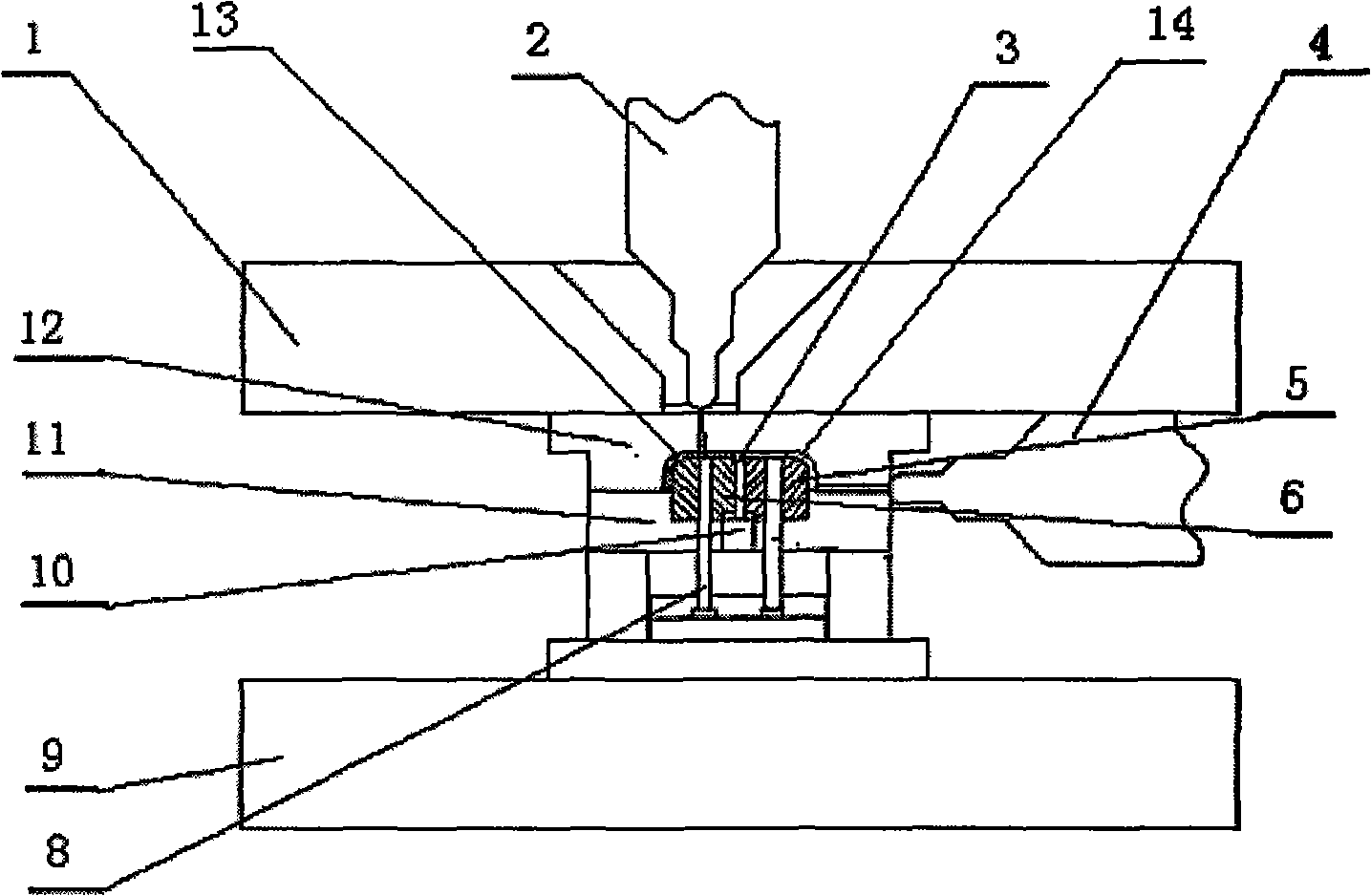

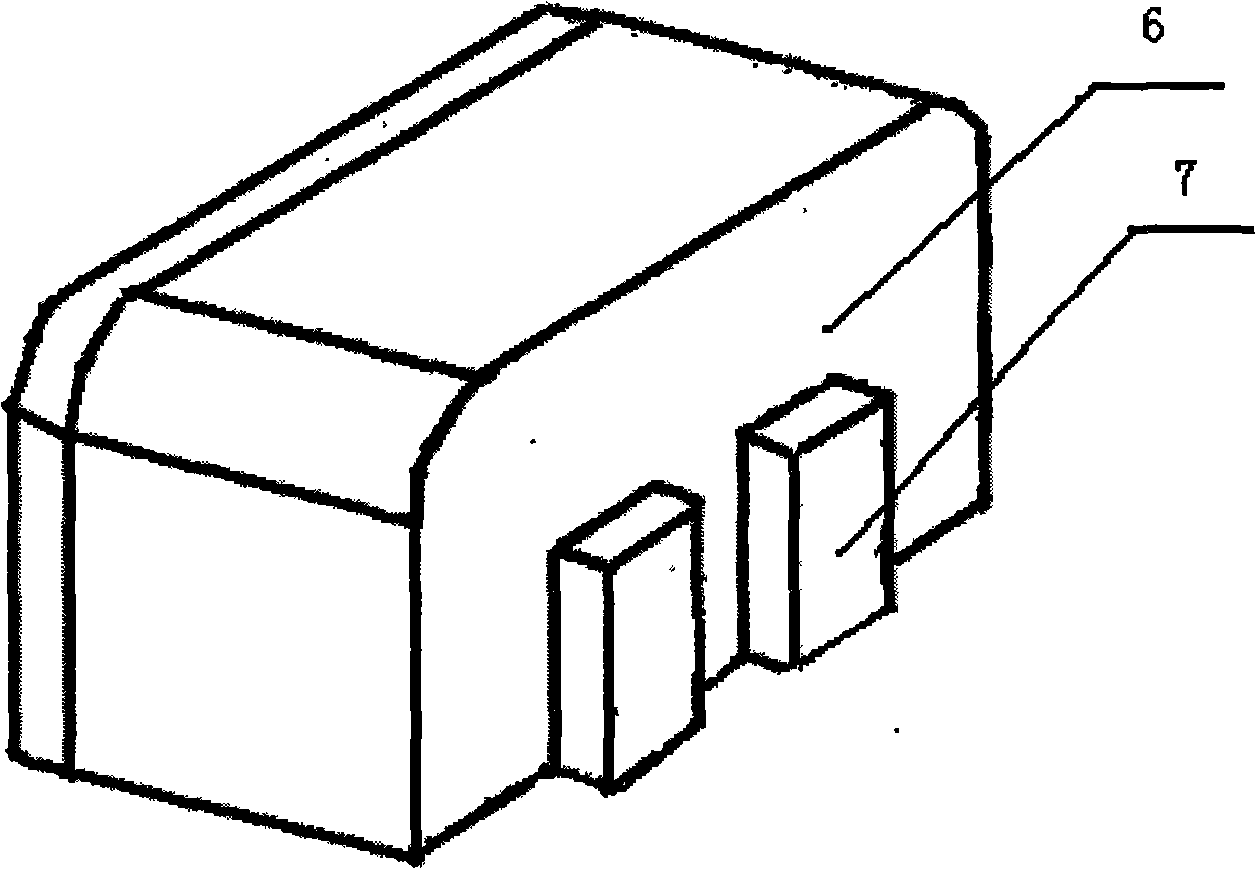

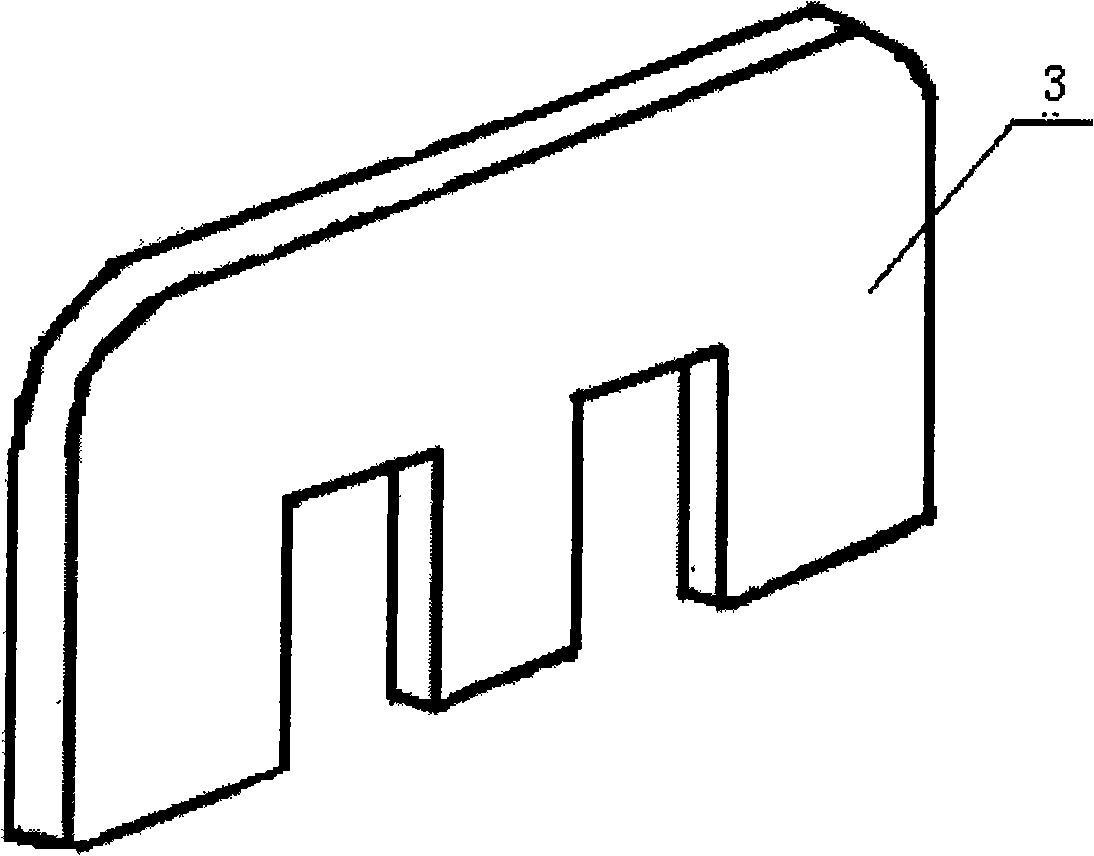

[0020] A two-color injection mold with a movable spacer and a preparation method of the present invention, wherein a two-color injection mold with a movable spacer comprises a convex mold, a concave mold 12, a fixed plate 1, a moving plate 9, an ejector rod 8, a concave mold The die base 11 and the feeding barrel, the punch includes a first punch 6 and a second punch 5, the first punch 6 and the second punch 5 are jointly embedded in the punch base 11, and the punch base is set in the injection molding On the motorized plate 9, the concave mold 12 is arranged on the fixed plate 1 of the injection molding machine. The profile surface of the concave die 12 and the profile surface of the convex mold form an injection cavity. The first injection cavity 13 and the second injection cavity 14 are respectively connected with the first barrel. 2. The second materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com