Wheel disc type injection mold containing vertical screw injection molding machine

An injection mold and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of long cooling time, affecting enterprise benefits, slow cooling speed, etc., and achieve the effect of improving enterprise benefits and increasing injection molding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

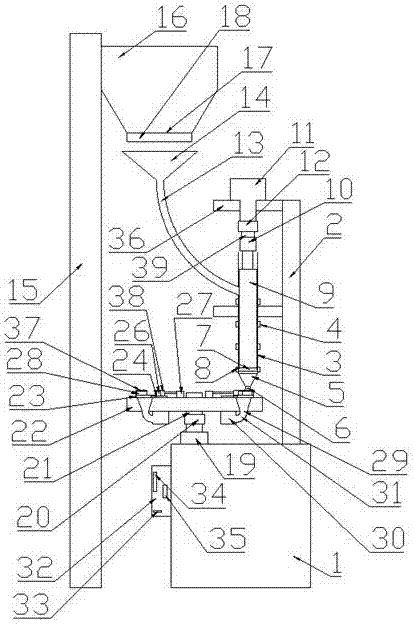

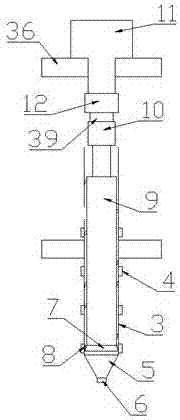

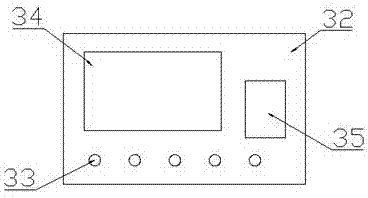

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a wheel-type vertical screw injection molding machine for holding injection molds, including an injection molding machine base 1, is characterized in that the injection molding machine base 1 is fixedly installed on the ground, and the injection molding machine base 1 is provided with Push material heating mechanism, said push material heating mechanism is fixedly installed on the support frame 2 on the upper surface of injection molding machine base 1, vertically placed and fixedly installed on the push material heating cylinder 3 on the support frame 2, fixedly installed on the push material The heater 4 on the outer surface of the heating cylinder 3, the nozzle 5 fixedly installed under the pusher heating cylinder 3, the pressure valve 6 fixedly installed on the nozzle 5, the piston 7 located inside the pusher heating cylinder 3, the piston 7 fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com