Making method of lightweight rubber shock absorption member for automobile

A production method and rubber shock absorption technology, which is applied in the field of auto parts manufacturing, can solve the problems of reducing the performance and service life of engineering plastics, the complex metal structure of plastic structural parts, and the high cost of rubber molds, so as to improve injection molding efficiency and shorten preheating Time, to ensure the effect of smooth bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

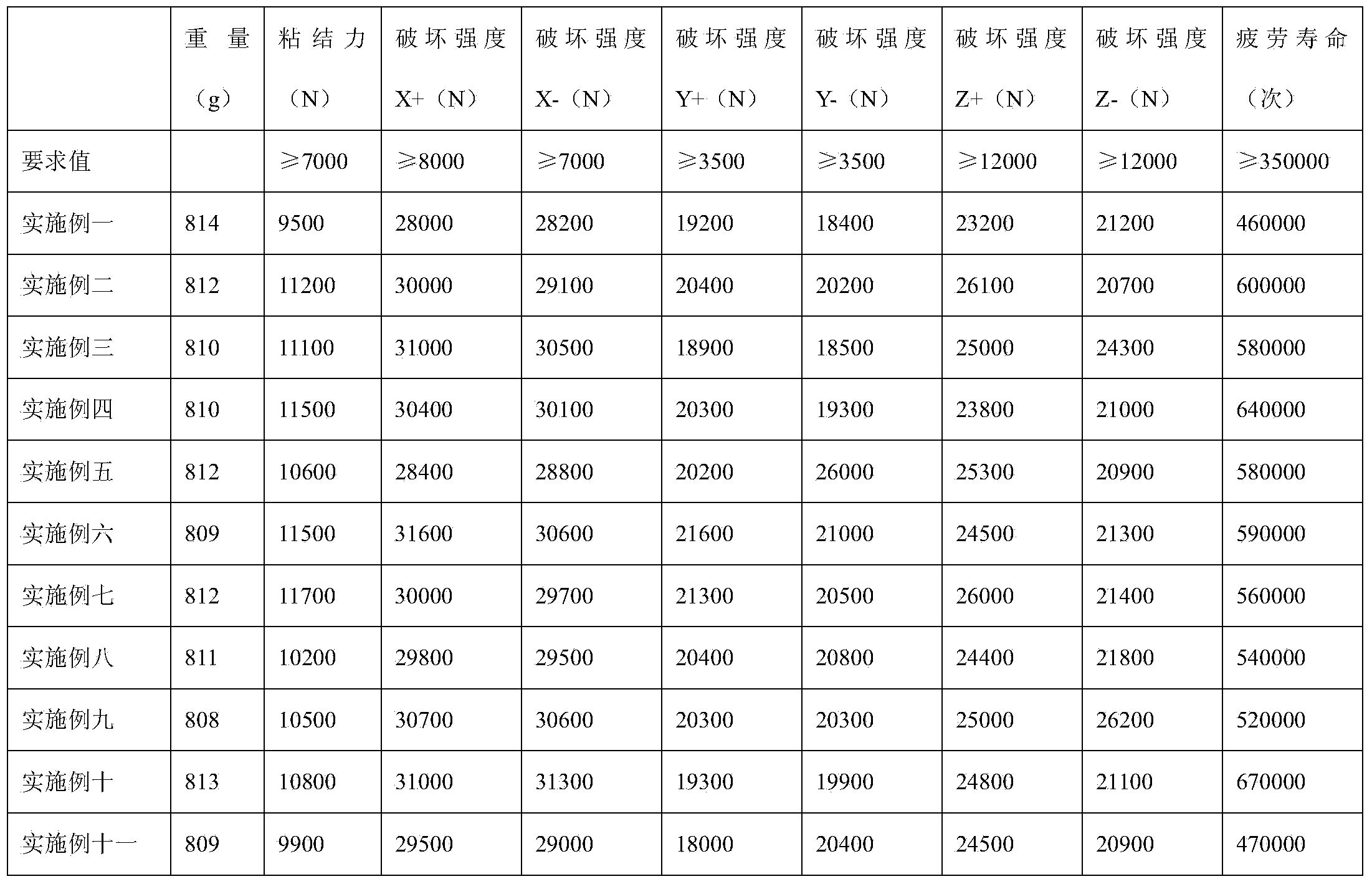

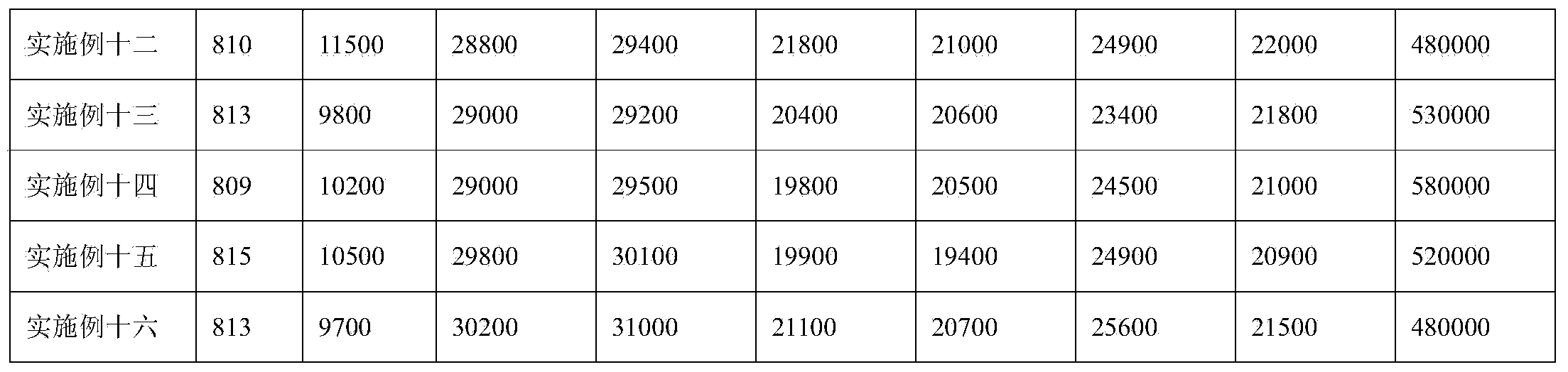

Embodiment 1

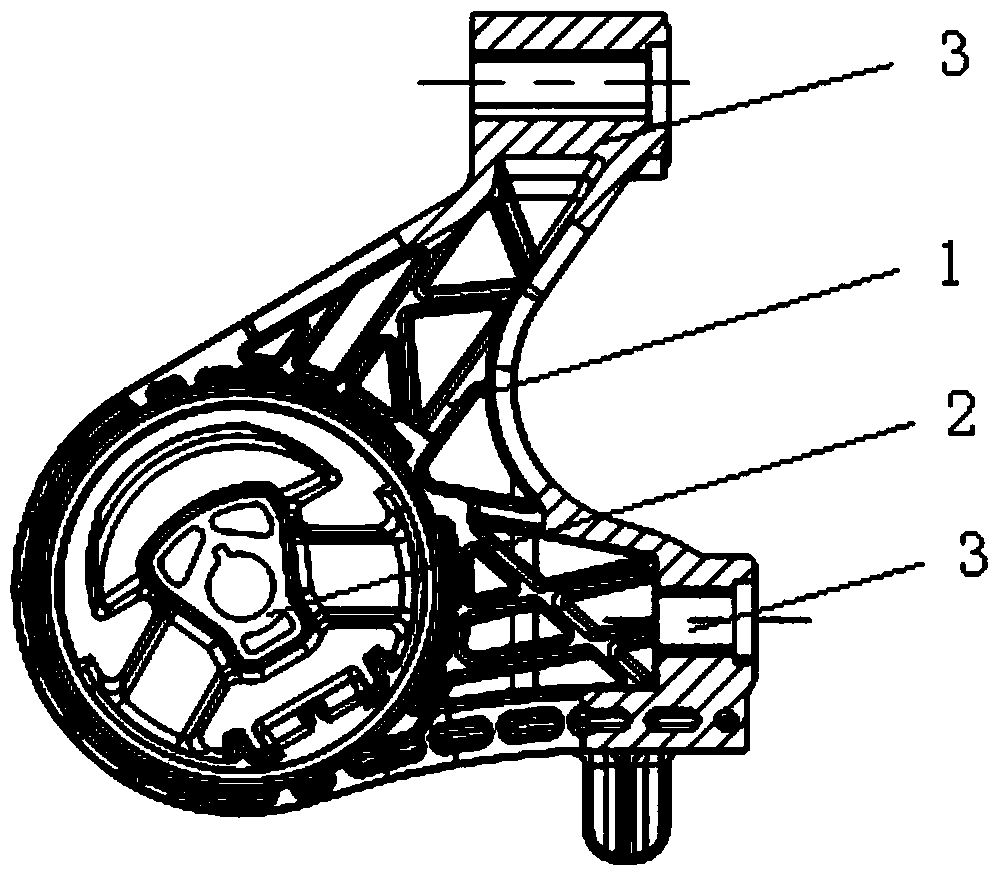

[0033] A method for manufacturing a lightweight rubber shock absorber for automobiles, wherein the rubber shock absorber is composed of a rubber main spring, a plastic bracket and a metal insert, and the manufacturing method includes the following steps:

[0034] (1) Vulcanization: Put the rubber main spring 2 into a vulcanization mold for vulcanization treatment, apply a vulcanization pressure of 10 MPa to the vulcanization mold, control the vulcanization treatment temperature to 140°C, and set the vulcanization treatment time to 20 minutes.

[0035] In this step, the material of the main rubber spring is selected from natural rubber, butadiene rubber, styrene-butadiene rubber or a mixture of several in any proportion.

[0036]In this step, the mixed rubber material used in the rubber main spring 2 is prepared by using the traditional mixing process, and the components of the mixed rubber are weighed: 100g natural rubber SVR3L, 5g zinc oxide ZnO, 1.5g stearic acid, 1g micro C...

Embodiment 2

[0046] Embodiment 2: Other parts are the same as Embodiment 1, the difference is that a vulcanization pressure of 20 MPa is applied to the vulcanization mold during vulcanization in step (1).

Embodiment 3

[0047] Embodiment 3: Other parts are the same as Embodiment 1, the difference is that a vulcanization pressure of 30 MPa is applied to the vulcanization mold during vulcanization in step (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com