Rotary disc type double-color injection mold forming process

A two-color injection molding and molding technology, applied in coating and other directions, can solve the problems of poor melt contact in the product, imperfect injection molding process, affecting production efficiency, etc., to improve injection molding efficiency, improve injection quality, and strong connectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

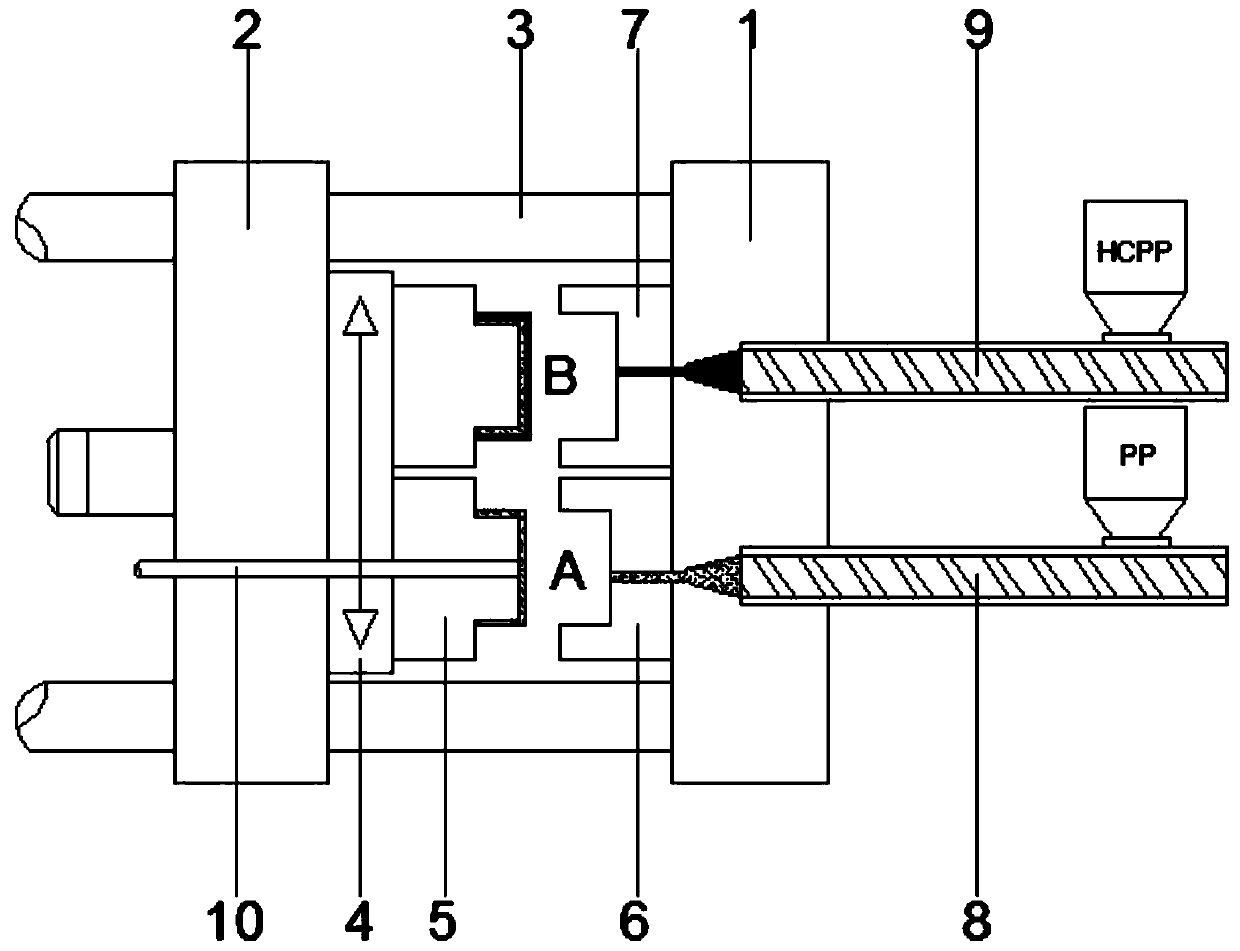

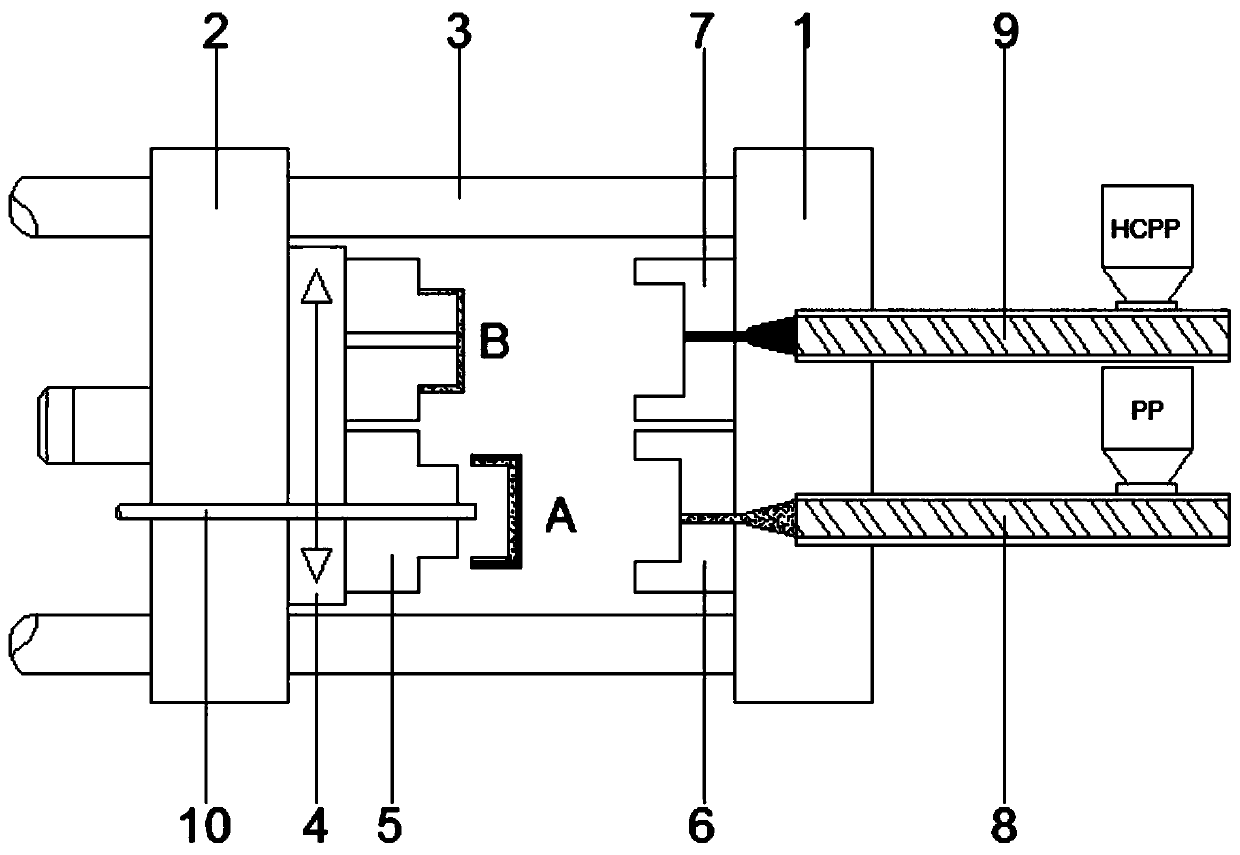

[0026] A turntable type two-color injection molding process, comprising: a fixed mold base 1, a movable mold base 2, a guide post 3, a turntable 4, a male mold core 5, a first female mold core 6, a second female mold core 7, a first Injection plastic tube 8, second injection plastic tube 9, thimble 10; the movable mold base 2 installed symmetrically along the central axis of the two-color injection molding machine moves forward through the guide post 3 to close the mold with the fixed mold base 1, and the first injection plastic tube 8 pairs Inject PP material into the first mold cavity A formed by the male mold core 5 and the first female mold core 6, the material temperature is controlled at 235°C, the injection time is 17.5-20s, and then the mold is opened, and the turntable 4 rotates 180°, and then Mold closing, the first plastic injection tube 8 is used to inject PP material into the cavity A of the first mold, the temperature of the material is controlled at 235°C, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com