Unloading control method and system for storage bins of concrete mixing station

A control method and technology for a control system, which are applied in the field of silo discharge control of a concrete mixing plant, can solve the problems of increasing the operating cost of the concrete mixing plant, affecting the production efficiency and quality of the concrete mixing plant, etc., so as to ensure the normal production efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

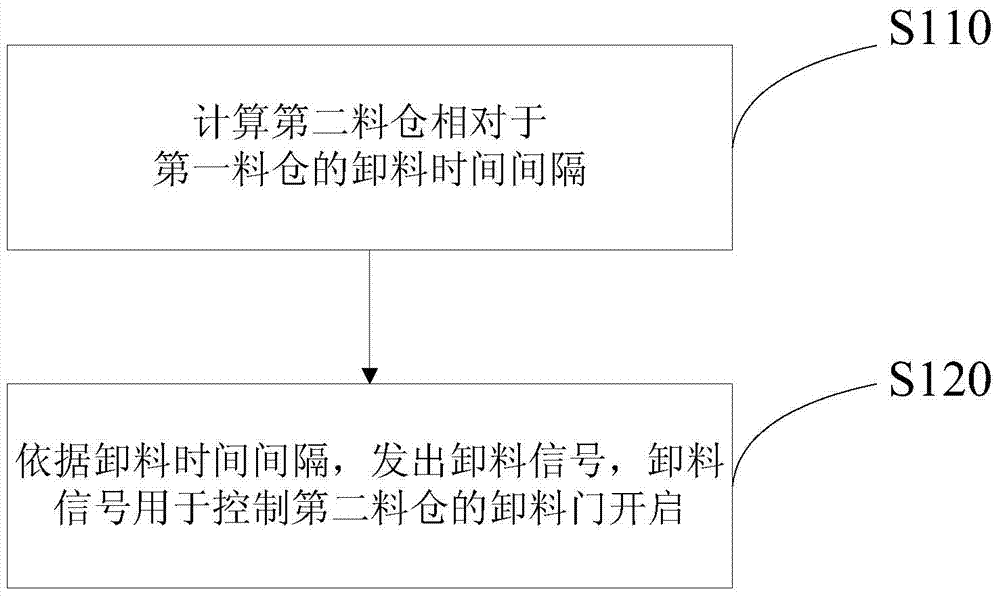

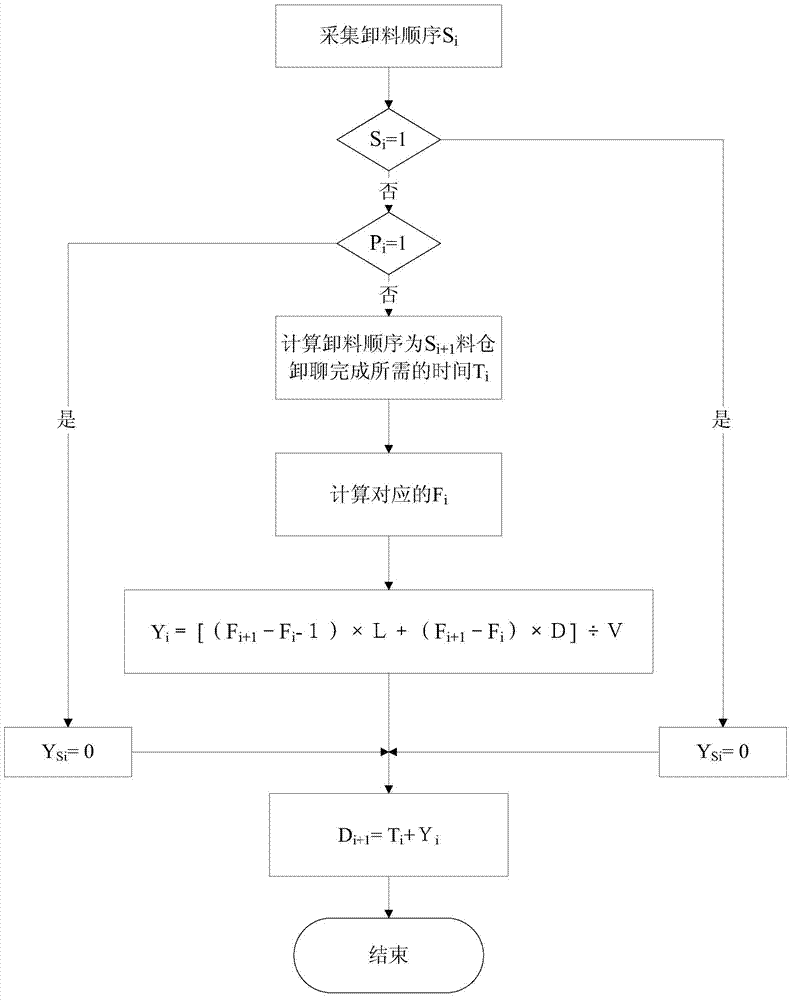

[0031] refer to figure 1 , figure 1 It is a flow chart of the steps of an embodiment of the method for controlling the unloading of the silo of the concrete mixing plant of the present invention. The embodiment of the control method for unloading the silo of the concrete mixing plant mainly includes two steps:

[0032] Calculation step S110, calculating the unloading time interval of the second silo relative to the first silo, the second silo is sequentially adjacent to the first silo;

[0033] The control signal sending step S120 is to send a discharge signal according to the discharge time interval, and the discharge signal is used to control the opening of the discharge door of the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com