Light-collecting compound sheet

A composite sheet and light-collecting technology, applied in the field of light-collecting composite sheets, can solve the problems of multi-thickness of optical elements, requiring a lot of assembly time, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the light-collecting composite sheet proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , as detailed below.

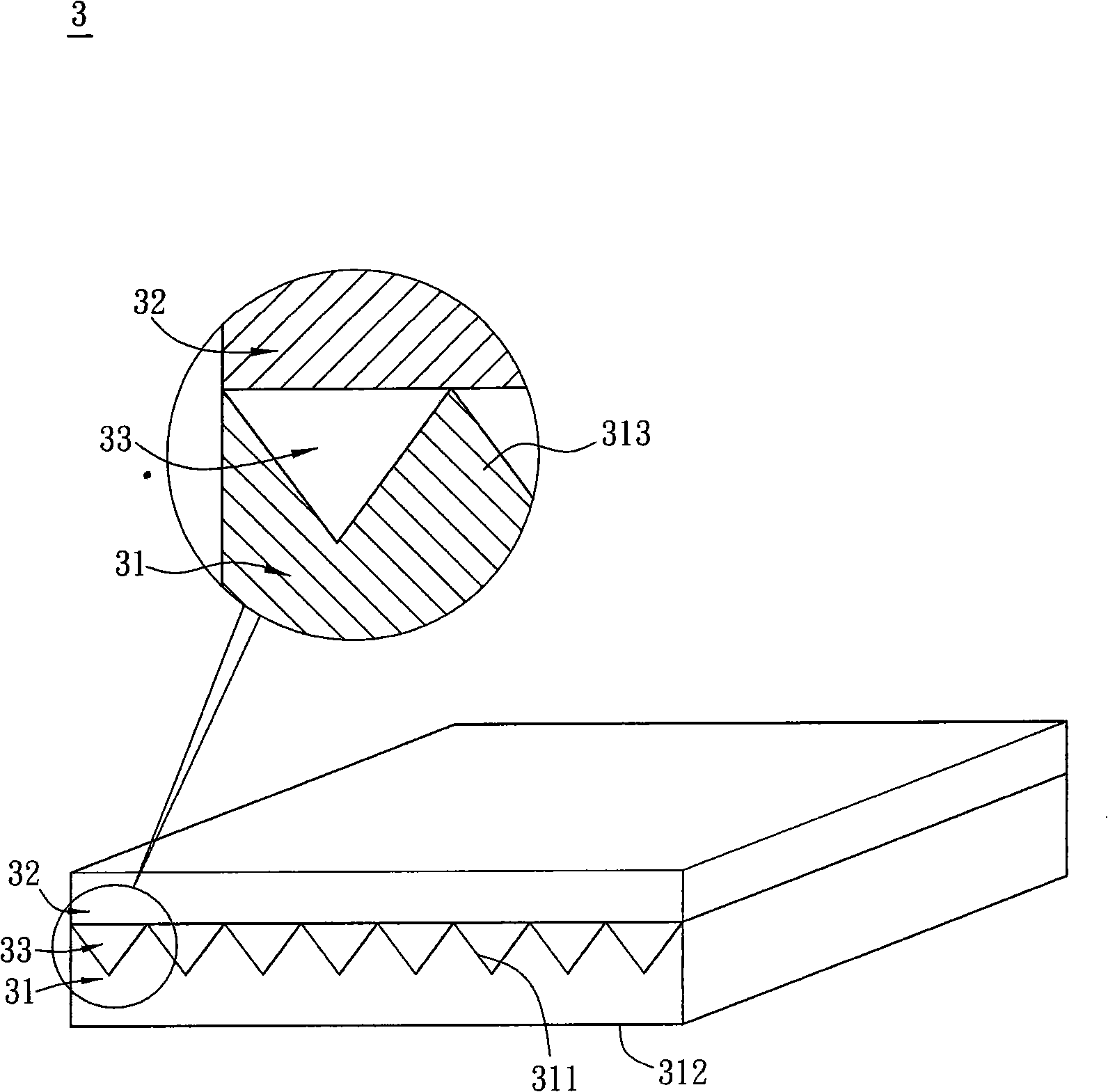

[0085] Please refer to image 3 As shown, a light-collecting composite sheet 3 according to the first embodiment of the present invention includes a first optical element 31 , a second optical element 32 and a plurality of cavities 33 . Wherein, the light-collecting composite sheet 3 is applied to a backlight module of a liquid crystal display device as an example, but it is not limited thereto. The light-collecting composite sheet 3 can also be applied in fields such as daily lighting, various displays, and medical instruments.

[0086] Please also refer to image 3 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com