Step slope type circular pipe automatic detection equipment

A slope-type, self-inspection technology, applied in the direction of sorting, etc., can solve the problems that unqualified products cannot be sorted and collected, and affect the detection of faster station rhythms, etc., to achieve high detection and transportation efficiency, material fixation and detection stability, and convenience in the later stage The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

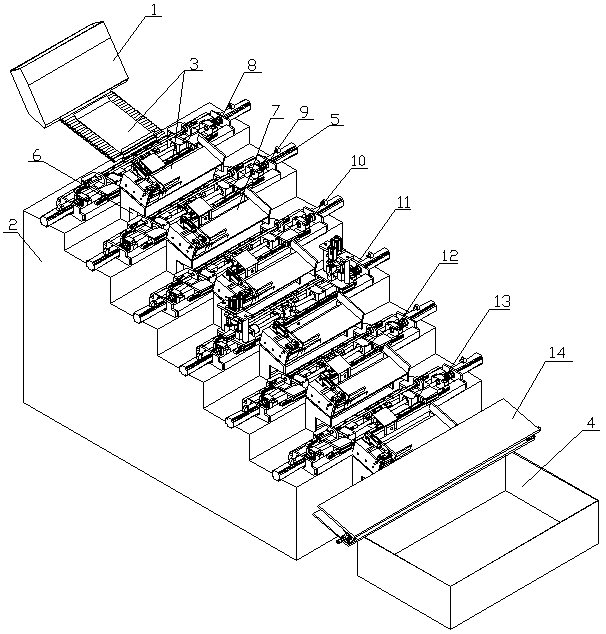

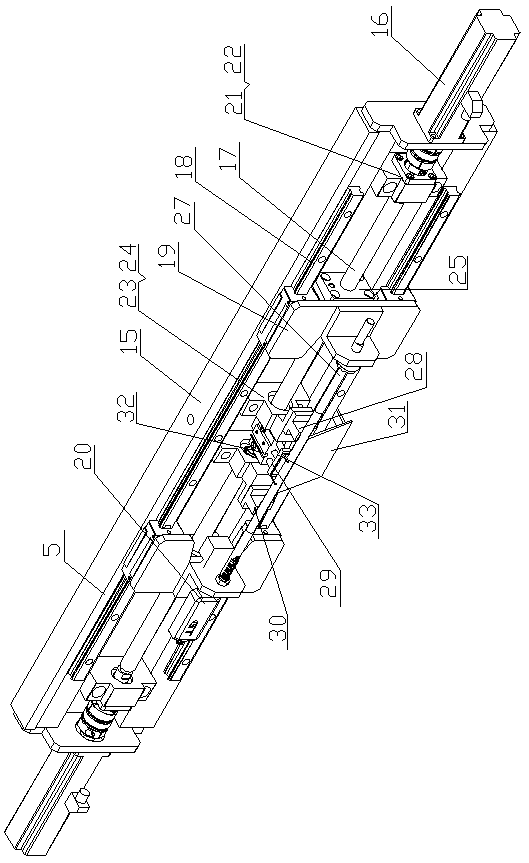

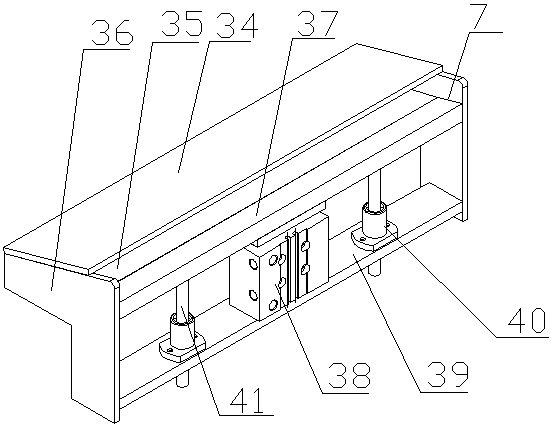

[0018] Such as figure 1 , 2 , 3, the self-testing equipment for ladder slope type circular tubes includes a feed bin 1, a ladder base 2, a slope material conveying system 3, and a storage bin 4. The feed bin 1 is arranged on the feed side of the ladder base 2, and the storage The silo 4 is set on the discharge side of the ladder base 2; the slope material conveying system 3 is set on the ladder base 2, the slope material conveying system 3 is set along the slope of the ladder base 2, and the feeding end of the slope material conveying system 3 is connected correspondingly At the discharge port of the feed bin 1, the discharge end of the slope material conveying system 3 is correspondingly connected to the feed port of the storage bin 4; The unit 5 is provided with waste recycling bins 6 of the upper steps on each step; the slope material conveying system 3 includes a plurality of material screening devices 7, and the material screening devices 7 are respectively arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com