Automatic tally method based on automatic tally system

An automatic and tallying technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of small size range, complex structure, and many transition links, and achieve a wide range of materials, improve system efficiency, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

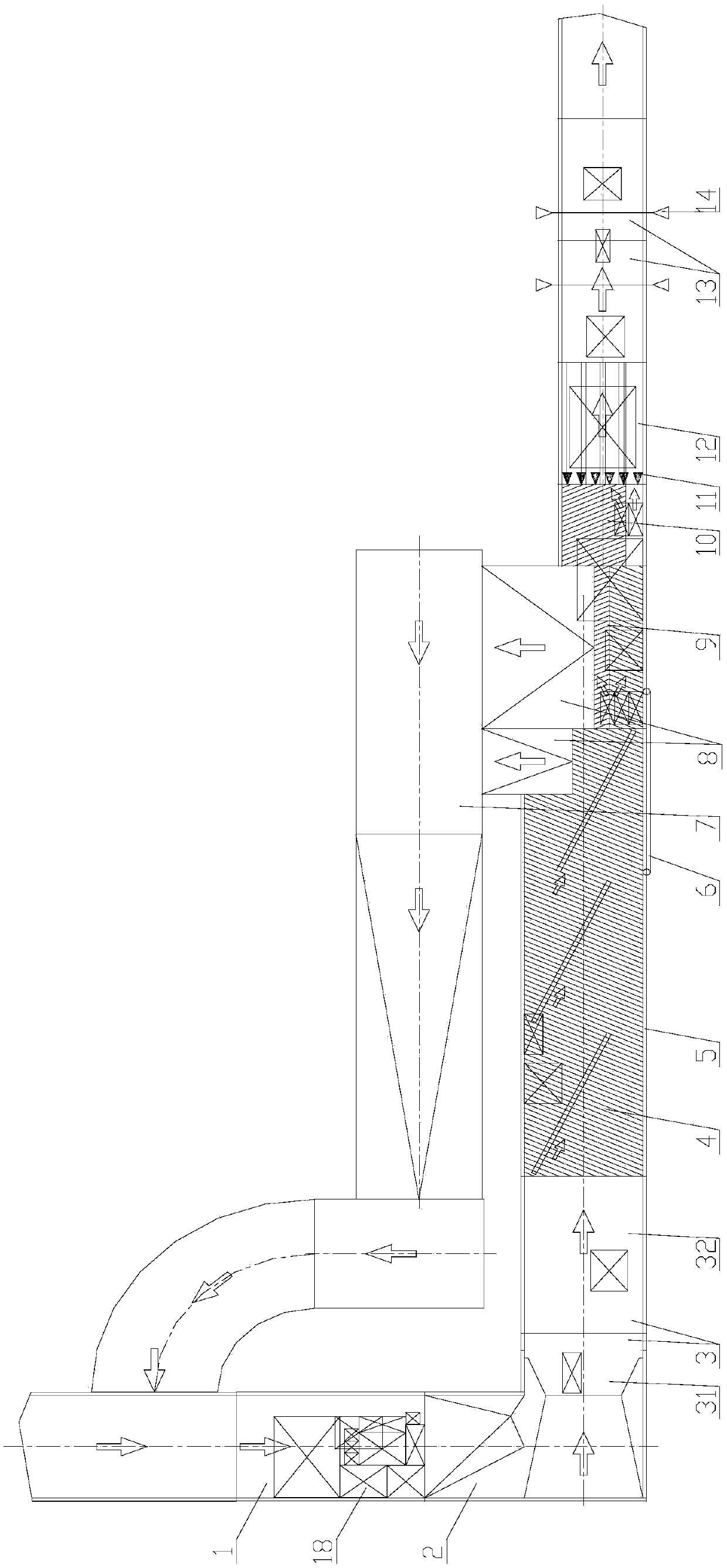

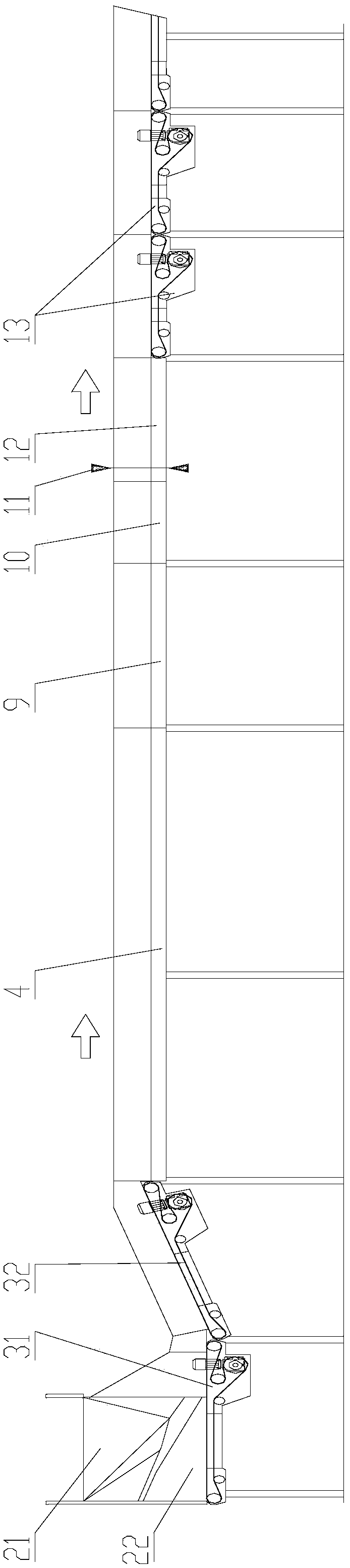

[0043] An automatic tally system, wherein a feeding belt conveyor (1), a special-shaped chute (2), a preliminary finishing belt unit (3), a side finishing machine (4), and a discharging conveyor are sequentially arranged along the conveying direction of the material (18). (9), a transverse separator (10), a longitudinal separator (12), and a flow control belt unit (13). The feeding belt conveyor (1) and the primary finishing belt unit (3) are vertically overlapped through the special-shaped chute (2); the guard plate (5) and the side vertical belt (6) are arranged on the right side of the side finishing machine (4). frame (41) side; the discharge chute inlet (81) is arranged at the output end of the side finishing machine (4), on the same side as the left frame (42) and the discharge roller (91) of the side finishing machine (4) ; The material return conveying unit (7) is connected to the discharge chute outlet (82) of the discharge chute (8), and finally the return material i...

Embodiment 2

[0045] On the basis of the aforementioned technical solutions, during specific implementation, the following features can also be included to form a technical solution to further achieve the purpose of the present invention:

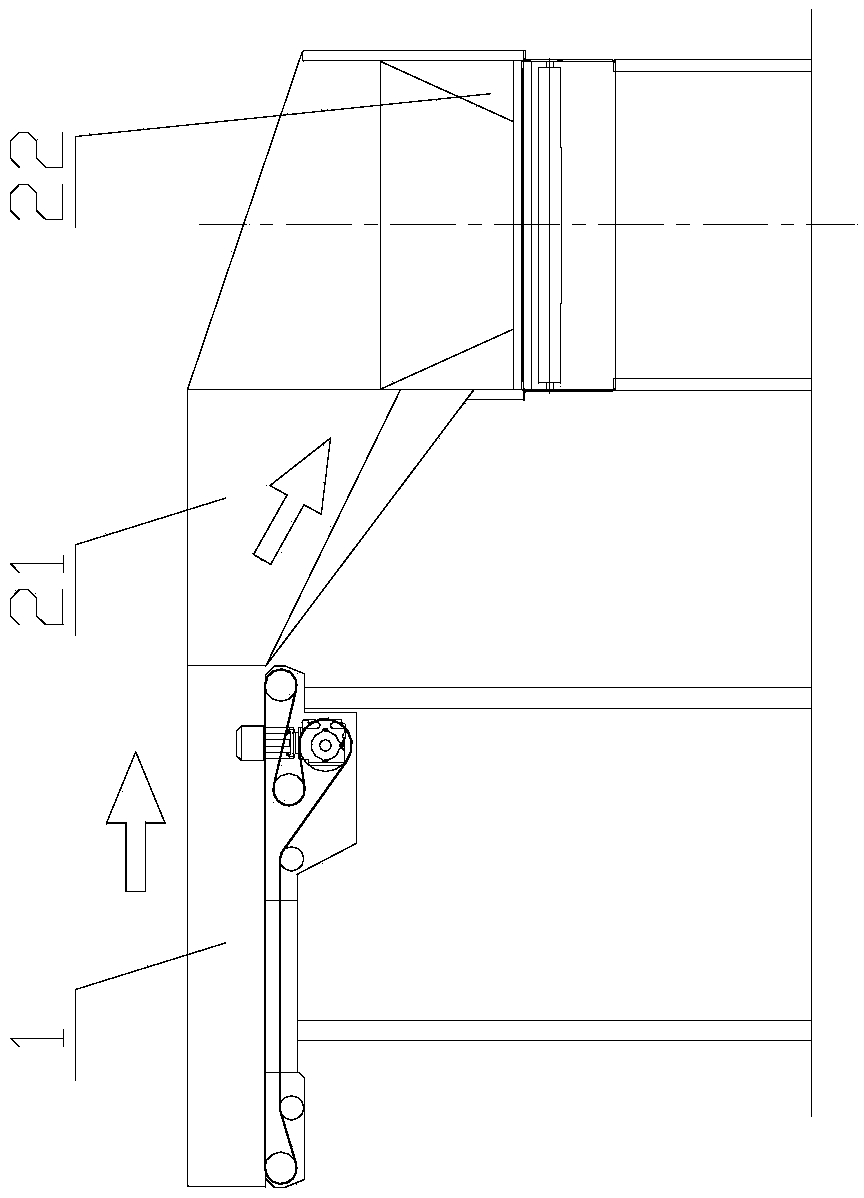

[0046] The special-shaped chute (2) includes two sections that are connected to each other and have a drop between each other and cause the material to flow to different chute I (21) and chute II (22). The outlet of the belt conveyor (1) is overlapped; the chute I (21) is provided with a plurality of sliding surfaces I (211), sliding surfaces II (212) and sliding surfaces III (213) with different angles along the flow direction from the inlet. , the end of each sliding surface is provided with a common sliding surface IV (214), the sliding surface IV (214) is connected to the chute II (22), and the outlet of the chute II (22) is connected to the initial finishing belt unit (3); The finishing belt unit (3) includes a flat-connected preliminary finishing b...

Embodiment 3

[0049] On the basis of the aforementioned technical solutions, during specific implementation, the following features can also be included to form a technical solution to further achieve the purpose of the present invention:

[0050] According to the flow detected by the flow detection device (14), the feeding belt conveyor (1) adjusts the speed or starts and stops the rhythm in real time, so as to control the feeding flow, balance the peaks and valleys of the flow, and prevent excessive materials (18) from entering the return conveying unit (7). );

[0051] For the profiled chute (2), see Figure 5 , including two sections of chute I (21) and chute II (22) that are connected to each other and have a drop between each other and cause the material to flow in different directions; preferably, chute I (21) and chute II (22) are horizontal The material flow direction in the projection direction is 90°. The material flow direction of the chute I (21) is the same as that of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com