Feeding self-adaptive cleaning device

A self-adapting, clearing technology, applied in the field of polishing and clearing of sanitary pipe fittings, can solve the problems of bulky, difficult to clear the workpiece, low efficiency, etc., and achieve the effect of improving the clearing efficiency, clearing quality and clearing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

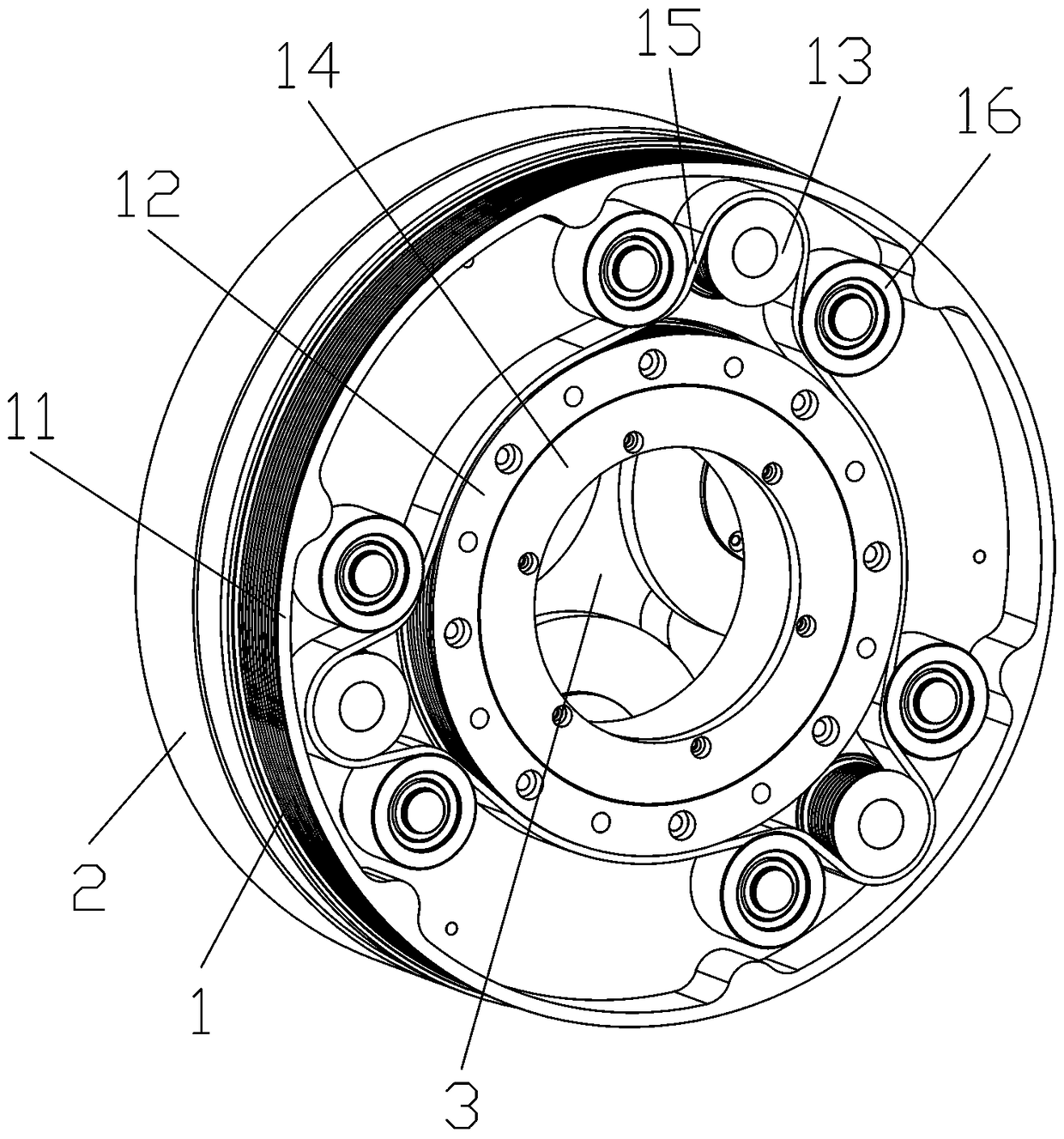

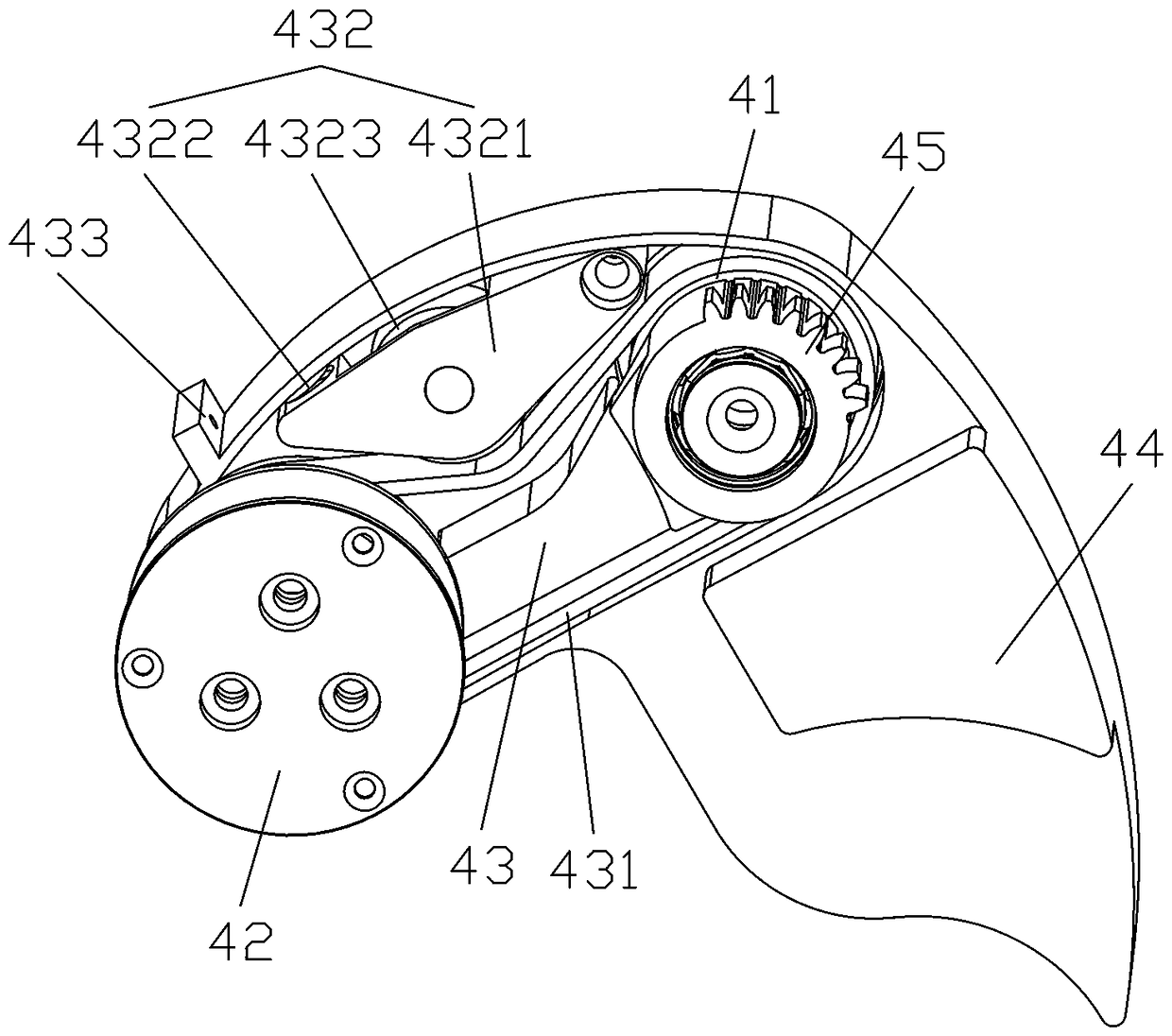

[0058] like figure 1 , the driven pulley 12 and the driven pulley 13 are multi-ribbed belt pulleys, which are connected to transmit power through the poly-ribbed belt 15, and each driven pulley 13 is installed on both sides with a pressing pulley 16 for pressing the poly-ribbed belt 15.

[0059] Therefore, the use of the driven pulley 12 and the driven pulley 13 as the V-ribbed pulley can increase the friction during transmission, and the use of the pressure pulley 16 can increase the contact area between the V-ribbed belt and the V-ribbed pulley, avoiding idling and reducing energy. loss.

Embodiment 2

[0061] The driven wheel 12 and the driven wheel 13 cooperate as planetary gears.

[0062] The driven wheel 12 and the driven wheel 13 cooperate as planetary gears, which can increase the load, increase the covering force of the cleaning wheel 5 on the workpiece, and improve the cleaning efficiency.

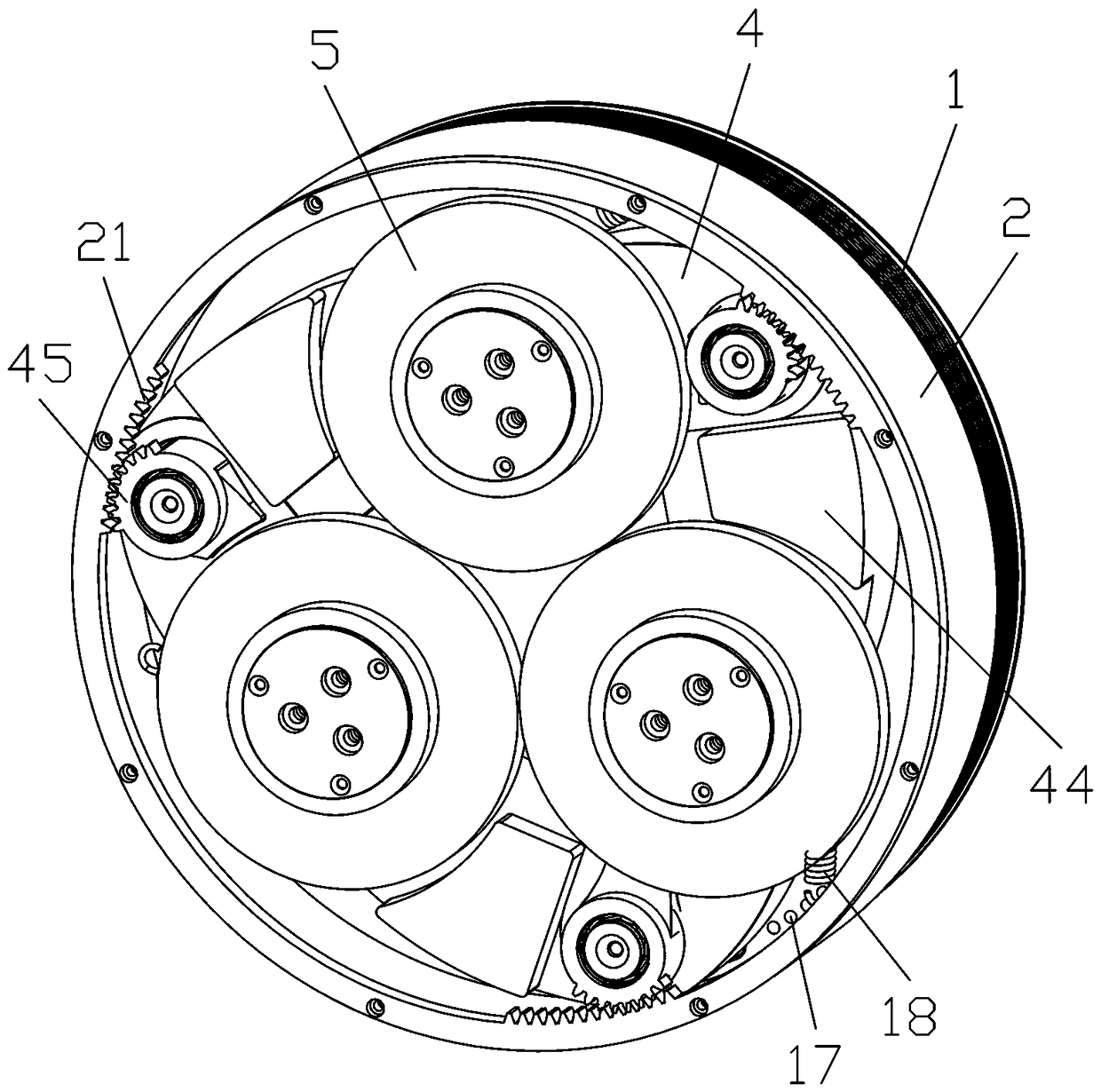

[0063] The numbers of the driven wheels 13 and the clearing units 4 are matched, and there are no less than two groups.

[0064] The driven wheel 13 and the light-clearing unit 4 are preferably set in 3-5 groups. When the light-clearing device is in 3-5 groups, the production cost is lower and the light-clearing effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com