Welded steel-coated-aluminum steel-aluminum conductor rail and production method thereof

A steel-aluminum composite and composite contact technology, applied in the direction of power rails, etc., can solve the problems of reducing the strength of the weld and affecting the continuity of the welding, so as to ensure the quality of the weld, improve the strength, and increase the cladding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

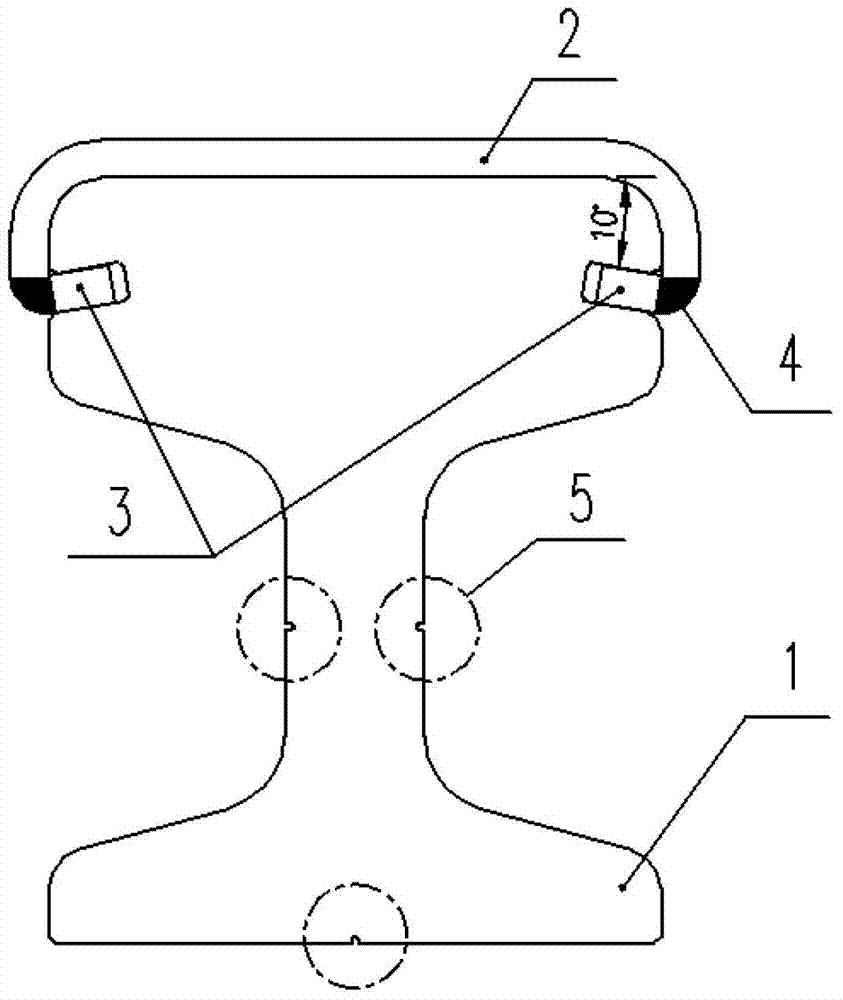

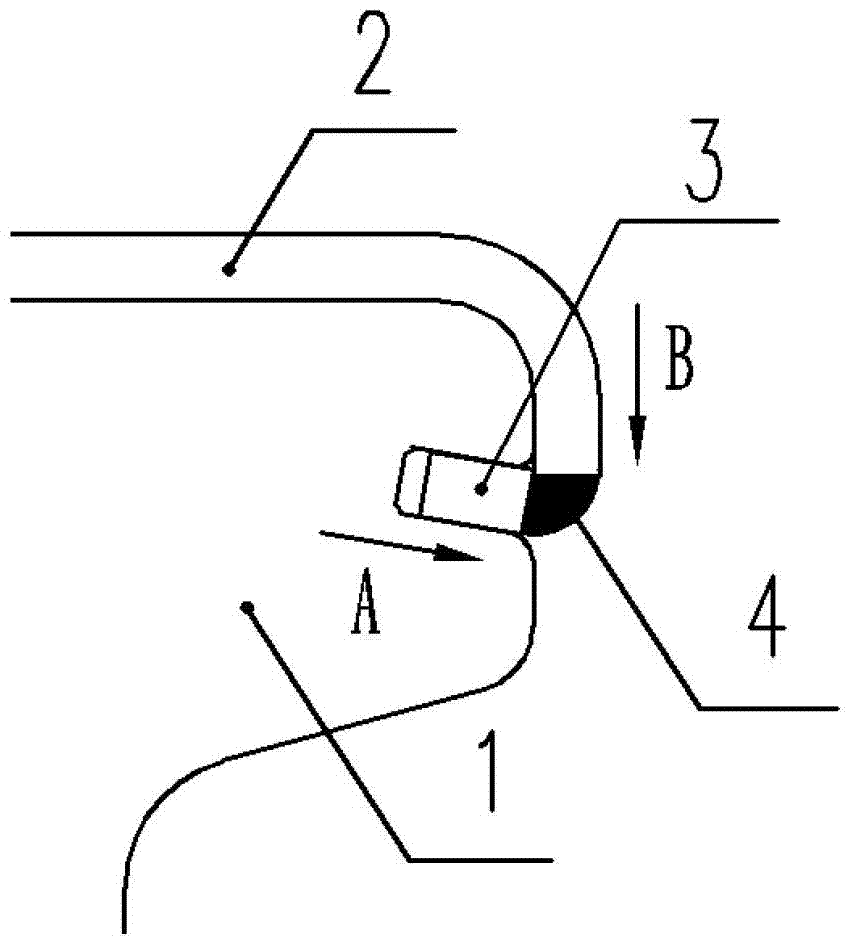

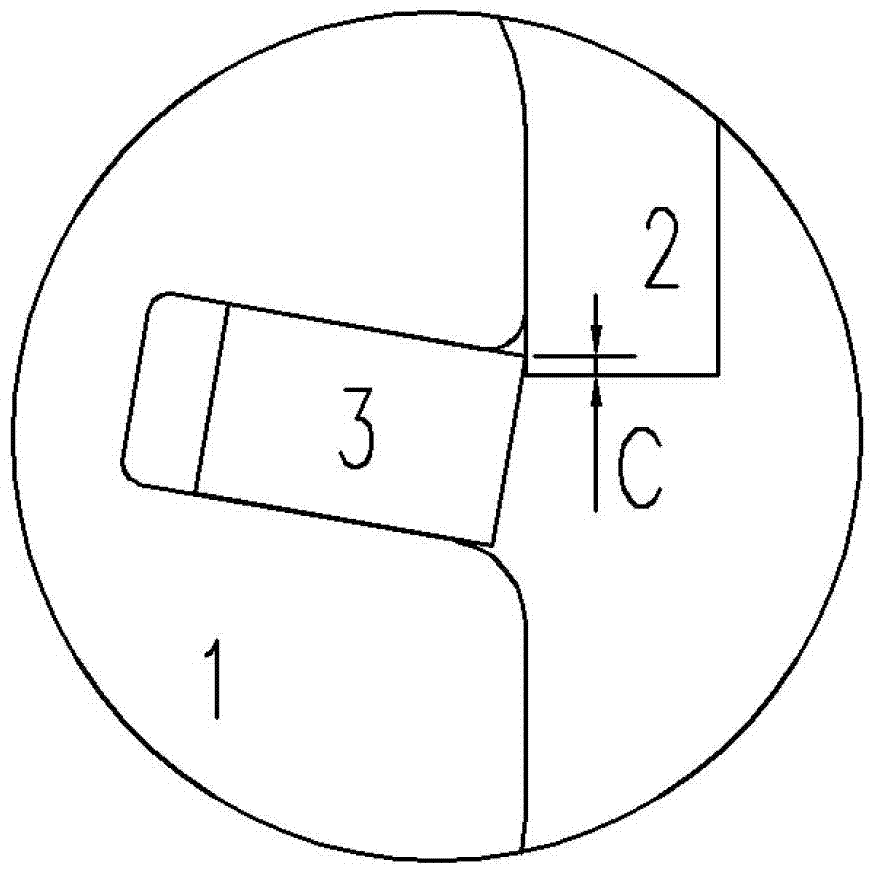

[0038] Such as Figure 1-3 As shown, the steel-aluminum composite contact rail of the ladle aluminum structure of the present invention is composed of an aluminum rail 1, a stainless steel strip 2 and two stainless steel strips 3; 1. The upper surface; the aluminum rail 1 is I-shaped, and there are inclined upward grooves on both sides of the upper end head, and the angle of the inclined upward grooves is 10°-15°; In the groove, make the side of the stainless steel strip 3 overlap with the inner surface of the two ends of the C-shaped stainless steel strip 2; use a MIG automatic welding machine to start welding at the overlap formed on both sides at the same time to form two fillet welds 4; Datum groove line 5 is set at the center line of both sides of the rail 1 waist and the center line of the bottom surface.

[0039] The inner surface of the C-shaped stainless steel strip 2 overlaps the outer surface of the stainless steel bar 3 by 1mm. The radian of the established refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com