Side draught type oil smoke exhausting device

A side-suction, oil fume exhaust technology, applied in the direction of oil fume removal, heating mode, household heating, etc., can solve the problems of oil fume pollution and escape, and achieve the effect of optimized fume exhaust effect and tight envelope range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

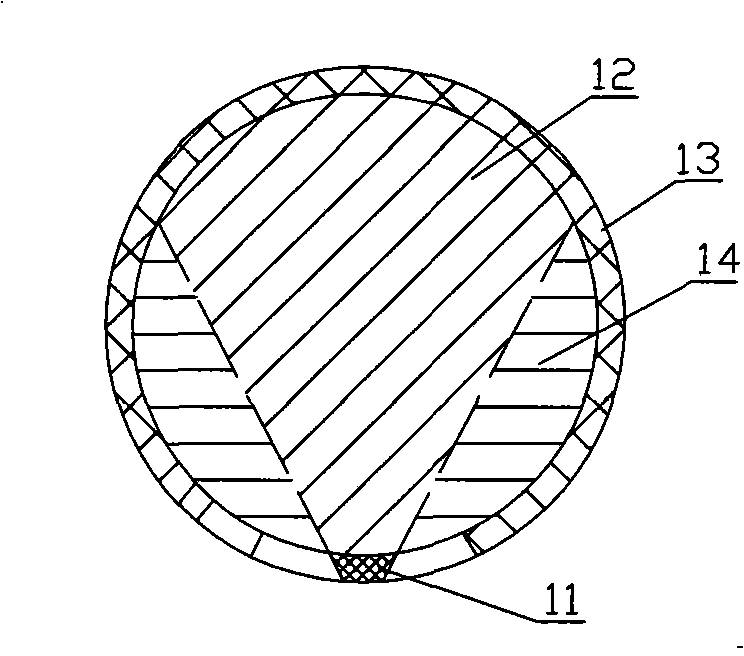

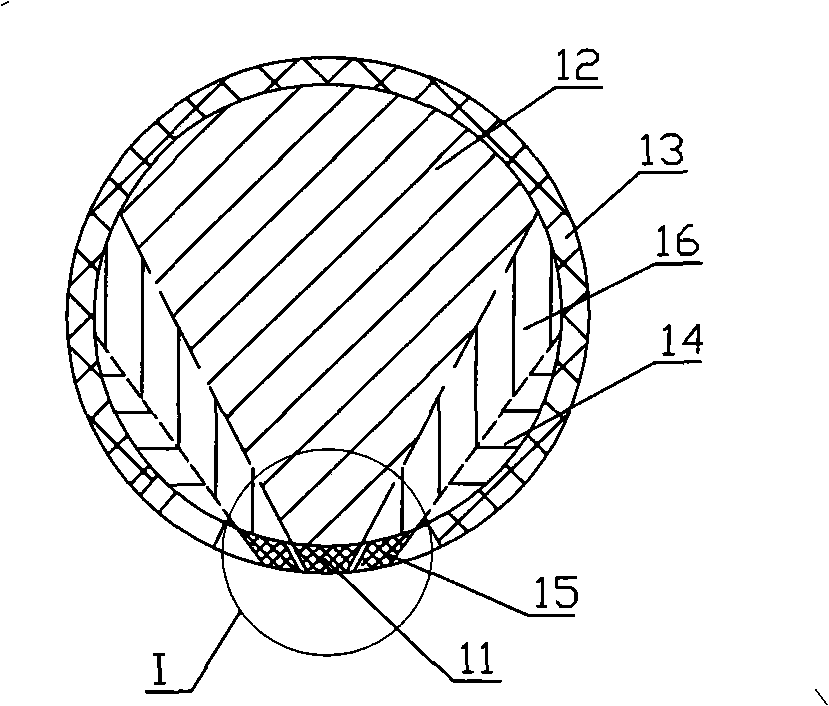

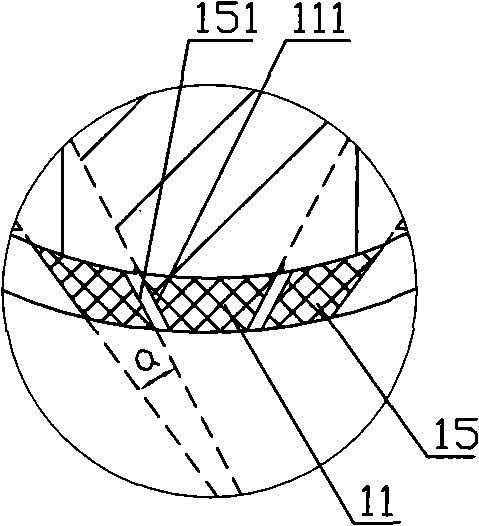

[0029] Such as Figures 2 to 8 As shown, it is an embodiment of a novel side-suction oil fume exhaust device of the present invention, including a bracket, a negative pressure wind ring generating device, and a positive pressure wind generating device. The negative pressure wind ring generating device includes an air inlet, and Air outlet connects air guide pipe one 21, blower fan 22 and exhaust pipe 23, and described positive pressure wind generating device comprises air outlet, and air outlet connects air guide pipe two 24, fan 22, and air outlet and air inlet share a blower fan 22, in An oil fume separator 25 is installed on the air guide pipe one 21 before the fan, and an oil fume separator 25 is installed after the fan 22 . The air inlet and air outlet rings are placed around the diffusion surface of the pollution source, and the air outlet includes a main air outlet 11 and at least one auxiliary air outlet 15 arranged on the side of the main air outlet. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com