A special additive for permeable concrete

A technology of permeable concrete and additives, applied in the field of building materials, can solve the problems of limited use range of permeable concrete, failure of pervious concrete strength and wear resistance, difficulty in balancing water permeability and strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

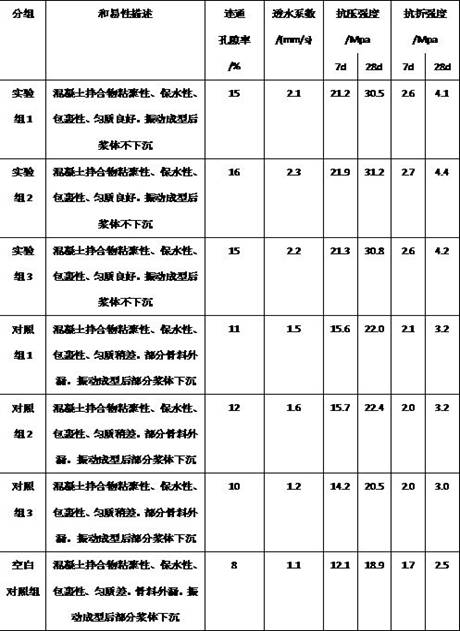

Examples

Embodiment 1

[0027] A special additive for permeable concrete, which is made of the following raw materials in parts by weight: 30 parts of slag micropowder, 25 parts of diatomite, 10 parts of modified phosphogypsum, 12 parts of starch compound, 2 parts of silicone defoamer, polycarboxylate 0.5 parts of acid water reducer, 1.2 parts of sodium carbonate;

[0028] The starch compound is prepared by the following steps:

[0029] 1) Weigh raw materials by weight: 10 parts of tapioca starch, 35 parts of PEG-2003, 2 parts of hydrochloric acid, 12 parts of N,N-dimethylformamide, 2 parts of sulfamic acid;

[0030] 2) Add tapioca starch and PEG-200 into the reaction kettle, stir evenly; then add hydrochloric acid, heat up to 70°C, react for 6 hours, filter to obtain hydrolyzed tapioca starch;

[0031] 3) Add N,N-dimethylformamide and sulfamic acid to the reaction kettle, stir evenly; then add hydrolyzed tapioca starch, heat up to 90°C, react for 1h, cool naturally to room temperature, and adjust t...

Embodiment 2

[0038] A special additive for permeable concrete, which is made of the following raw materials in parts by weight: 35 parts of slag micropowder, 20 parts of diatomite, 15 parts of modified phosphogypsum, 10 parts of starch compound, 1 part of silicone defoamer, polycarboxylate 0.8 parts of acid water reducer, 1 part of sodium carbonate;

[0039] The starch compound is prepared by the following steps:

[0040] 1) Weigh raw materials by weight: 10 parts of tapioca starch, 35 parts of PEG-2003, 2 parts of hydrochloric acid, 12 parts of N,N-dimethylformamide, 2 parts of sulfamic acid;

[0041] 2) Add tapioca starch and PEG-200 into the reaction kettle, stir evenly; then add hydrochloric acid, heat up to 70°C, react for 6 hours, filter to obtain hydrolyzed tapioca starch;

[0042] 3) Add N,N-dimethylformamide and sulfamic acid into the reaction kettle, stir evenly; then add hydrolyzed tapioca starch, heat up to 90°C, react for 1h, cool naturally to room temperature, and adjust the...

Embodiment 3

[0049] A special additive for permeable concrete, which is made of the following raw materials in parts by weight: 40 parts of slag micropowder, 15 parts of diatomite, 20 parts of modified phosphogypsum, 8 parts of starch compound, 0.5 part of silicone defoamer, polycarboxylate 1 part of acid water reducer, 0.8 part of sodium carbonate;

[0050] The starch compound is prepared by the following steps:

[0051] 1) Weigh raw materials by weight: 10 parts of tapioca starch, 35 parts of PEG-2003, 2 parts of hydrochloric acid, 12 parts of N,N-dimethylformamide, 2 parts of sulfamic acid;

[0052]2) Add tapioca starch and PEG-200 into the reaction kettle, stir evenly; then add hydrochloric acid, heat up to 70°C, react for 6 hours, filter to obtain hydrolyzed tapioca starch;

[0053] 3) Add N,N-dimethylformamide and sulfamic acid to the reaction kettle, stir evenly; then add hydrolyzed tapioca starch, heat up to 90°C, react for 1h, cool naturally to room temperature, and adjust the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com