Hose feeding self-locking and conveying device of hose assembling machine

A conveying device and assembly machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as slipping and shorten assembly time, and achieve the effects of saving production costs, enhancing competitiveness, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

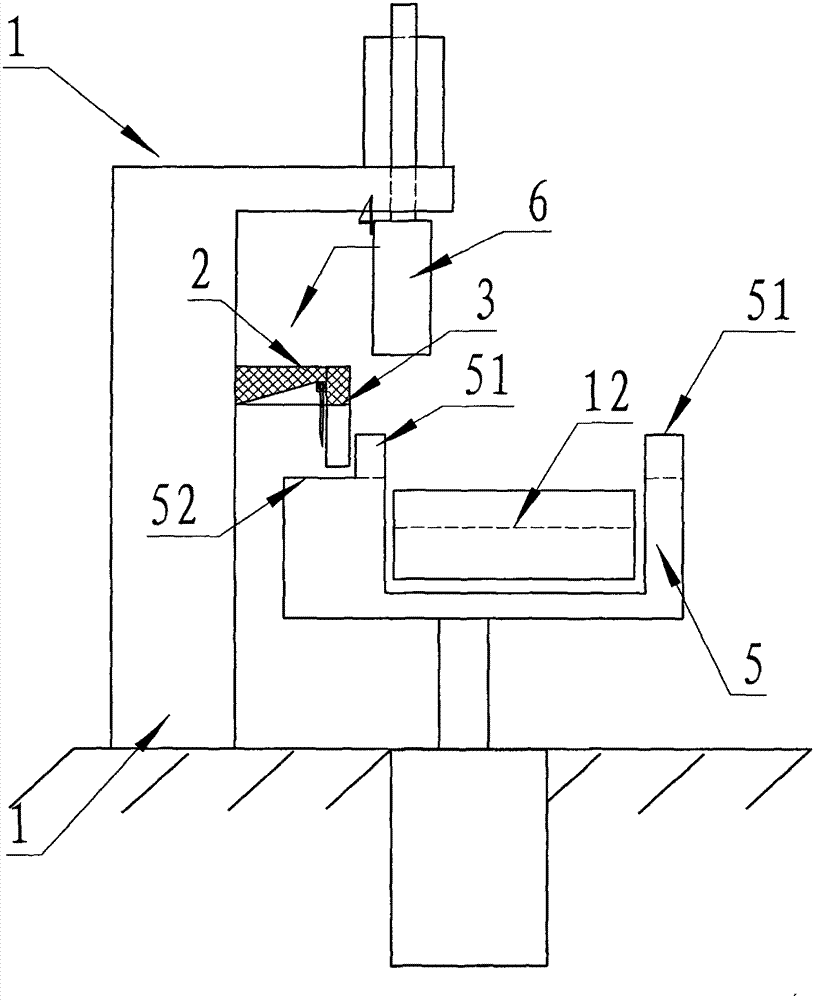

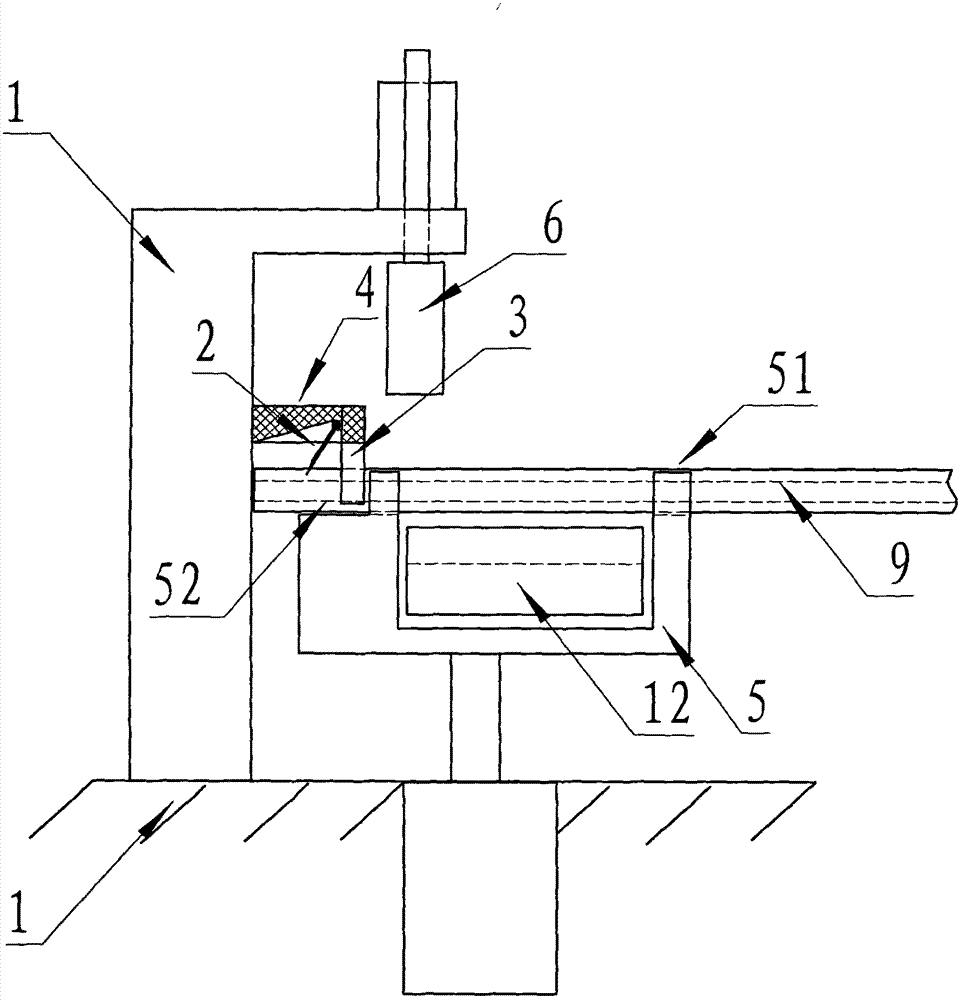

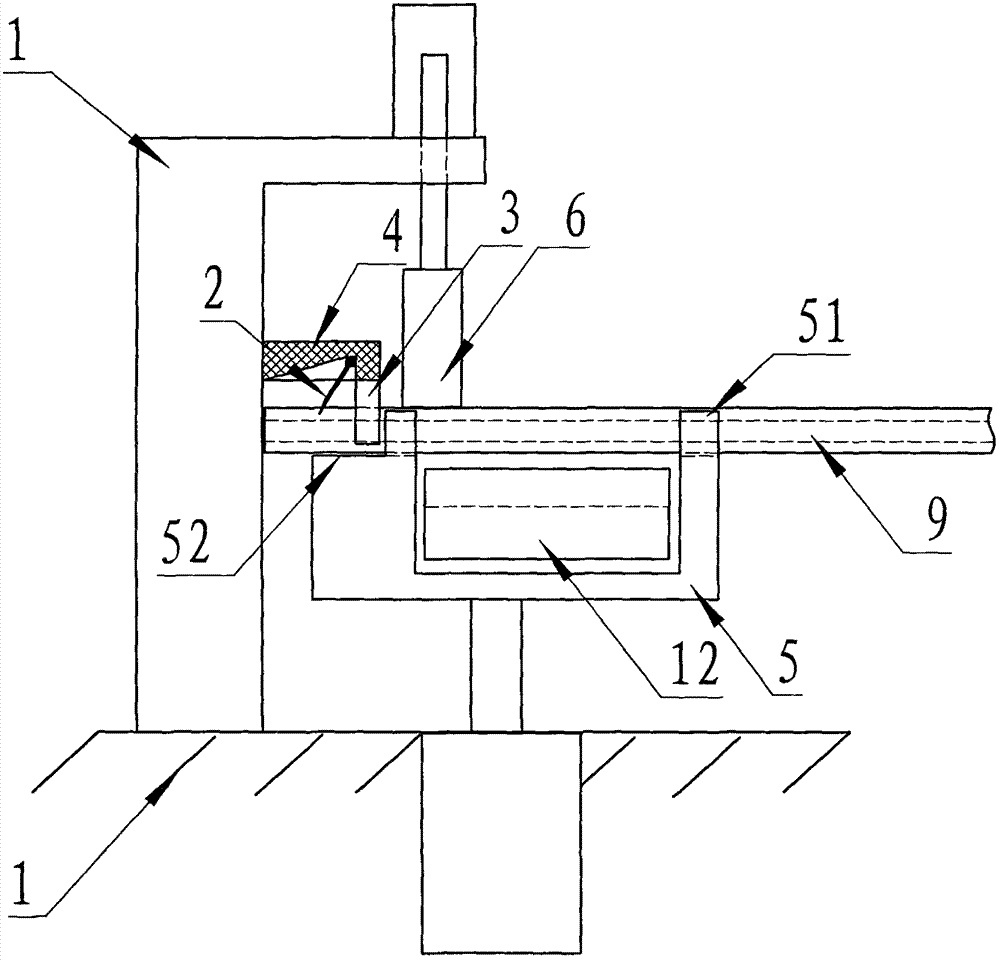

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0021] Such as Figure 1-Figure 6 As shown, the socket piece 3 and the feeding movable mechanism 5 for inserting at least one or more hoses 9, several locking pieces 2 for automatically locking several hoses 9, and the fixing for fixing the locking piece 2 part 4 and a presser 6 for pressing and pasting several hoses 9 without slipping; the socket part 3 is fixedly connected with the fixing part 4, and the fixing part 4 is fixedly connected on the hose assembly machine frame 1, located on Above the upper plane of the feeding movable mechanism 5, the lower end surface of the socket part 3 is close to the upper plane when the feeding movable mechanism 5 rises. The two sides of the mechanism 12 move up and down, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com