Lumber feeding mechanism

A feeding mechanism and feeding technology, applied in the direction of conveyors, conveyor objects, manipulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

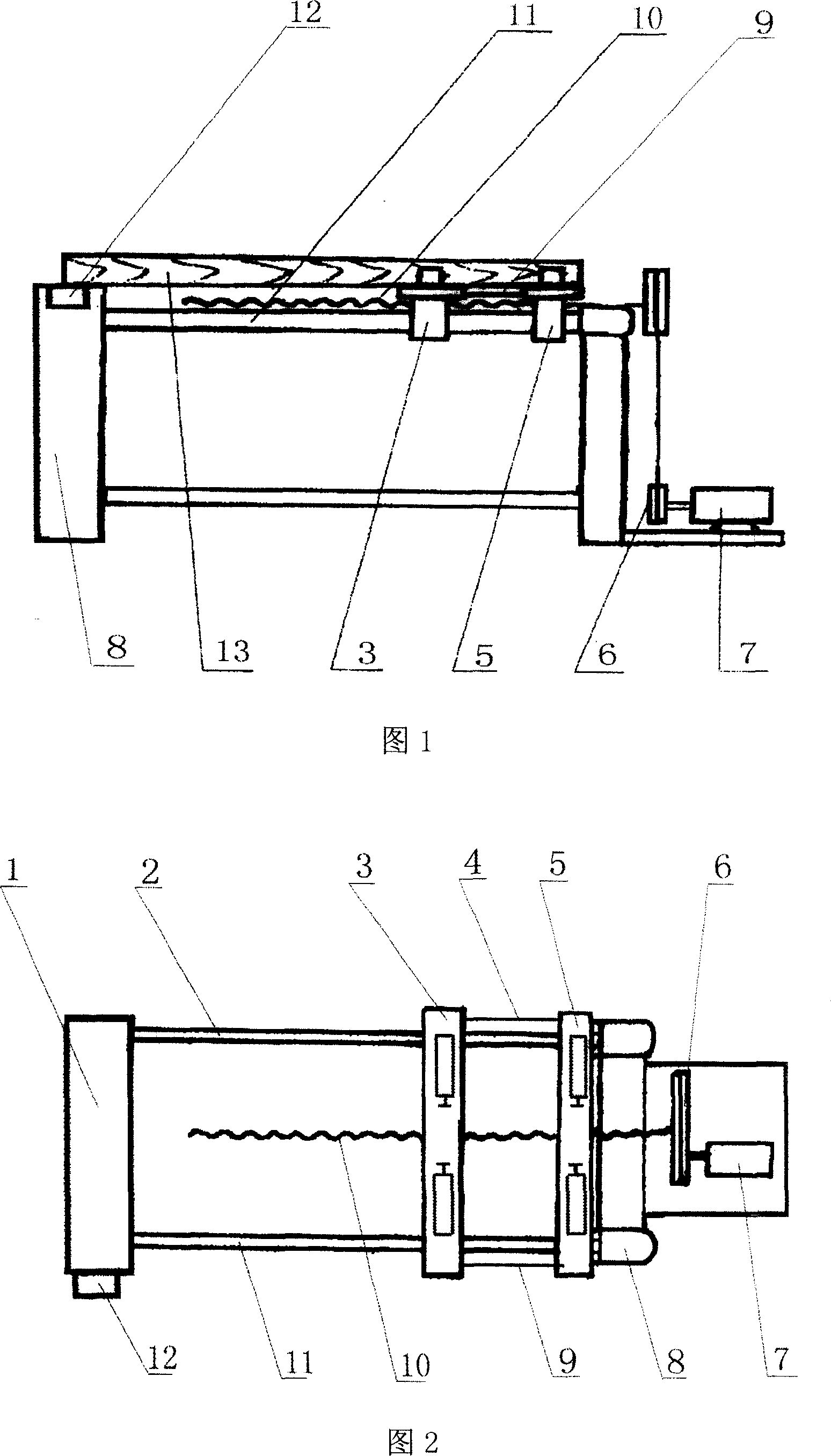

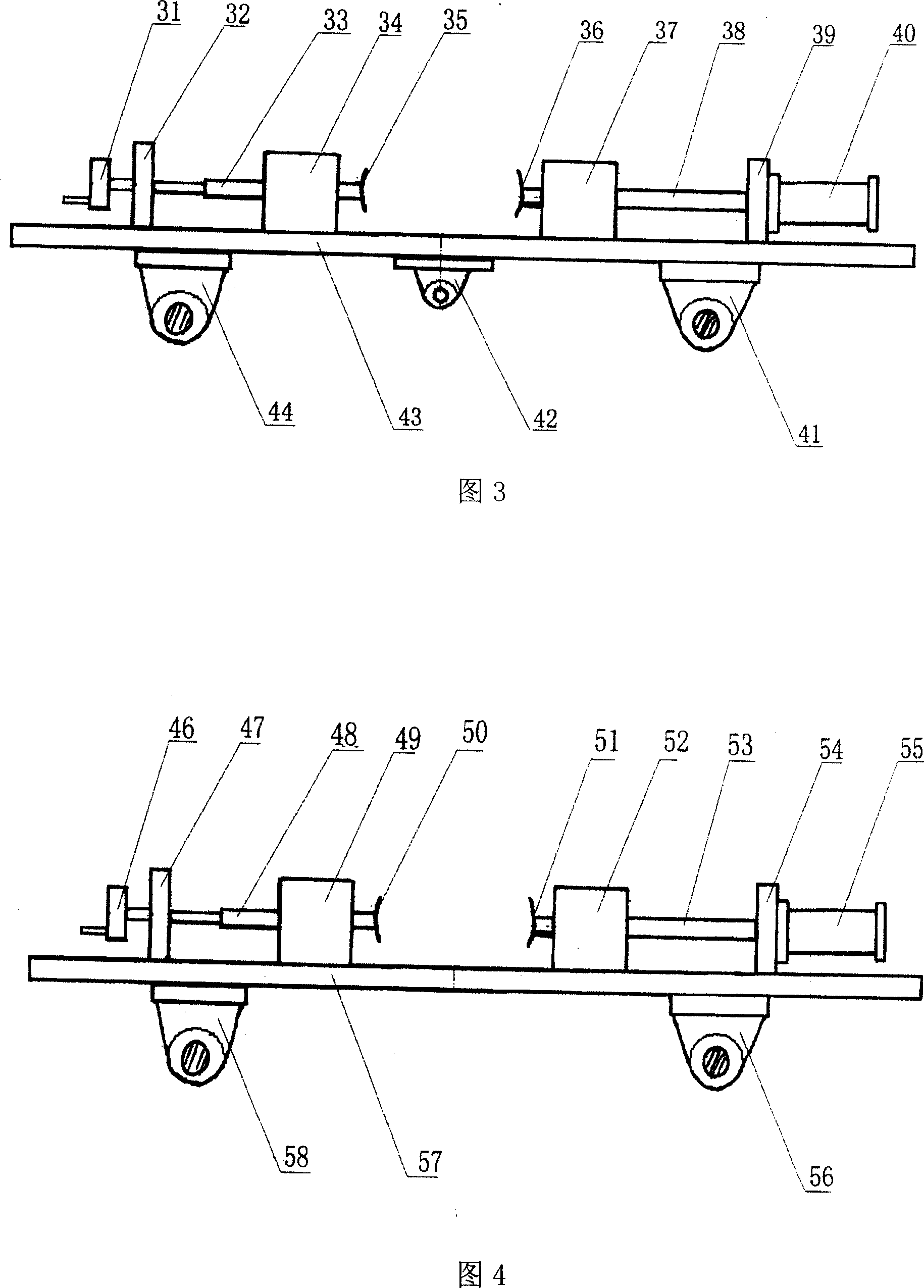

[0019] As shown in Fig. 1, Fig. 2, Fig. 3, and Fig. 4, the log feeding mechanism includes a power mechanism, two feeding bodies 3, 5, and a frame 8, and the upper part of the frame 8 has two parallel rails used as slide rails. Round pipes 2, 11 and screw mandrels (10) parallel to the axis of the round pipes, two feeding bodies 3, 5 move back and forth along the two guide rails 2, 11, one end of the length direction of the frame 8 has a working table 1, and the power The mechanism comprises a motor (7) and a transmission mechanism (6) located at the opposite end of the worktable (1) of the frame (8), and the transmission mechanism (6) is connected with the screw rod (10) provided.

[0020] The second feed body 3 of the two feed bodies is close to the work surface 1 of the frame, and the first feed body 5 includes a rectangular first feed body panel 43, two log clamps fixed on the first feed body panel 43 upper surface. The first clamp group, the threaded seat 42 that is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com