Electric pencil sharpener

a technology of electric pencils and sharpeners, which is applied in the direction of sharpeners, printing, manufacturing tools, etc., can solve the problems of high manufacturing cost and inconvenient operation of such electric pencil sharpeners by peopl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

” one will understand how the features of the system and methods provide several advantages over traditional electric pencil sharpeners.

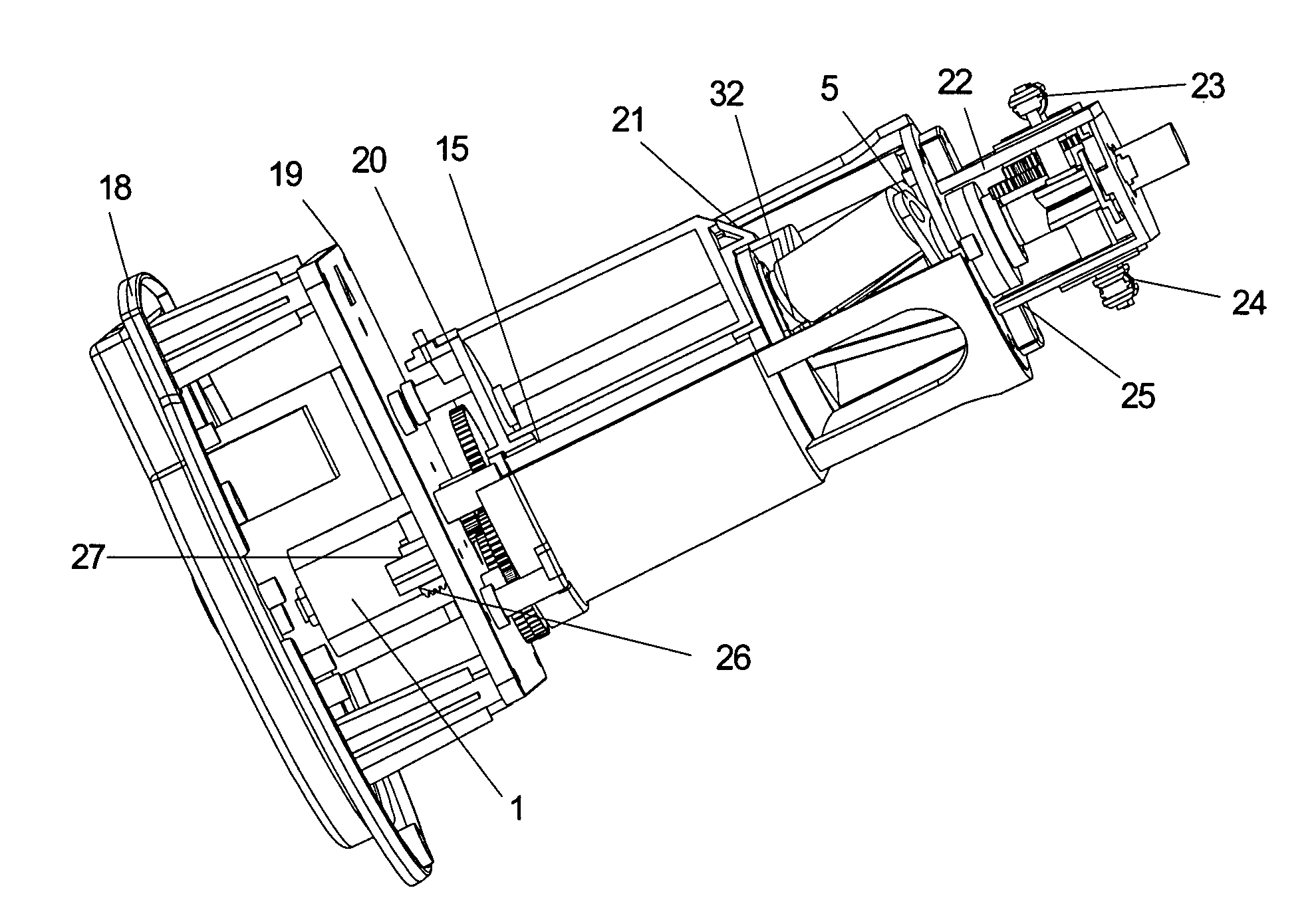

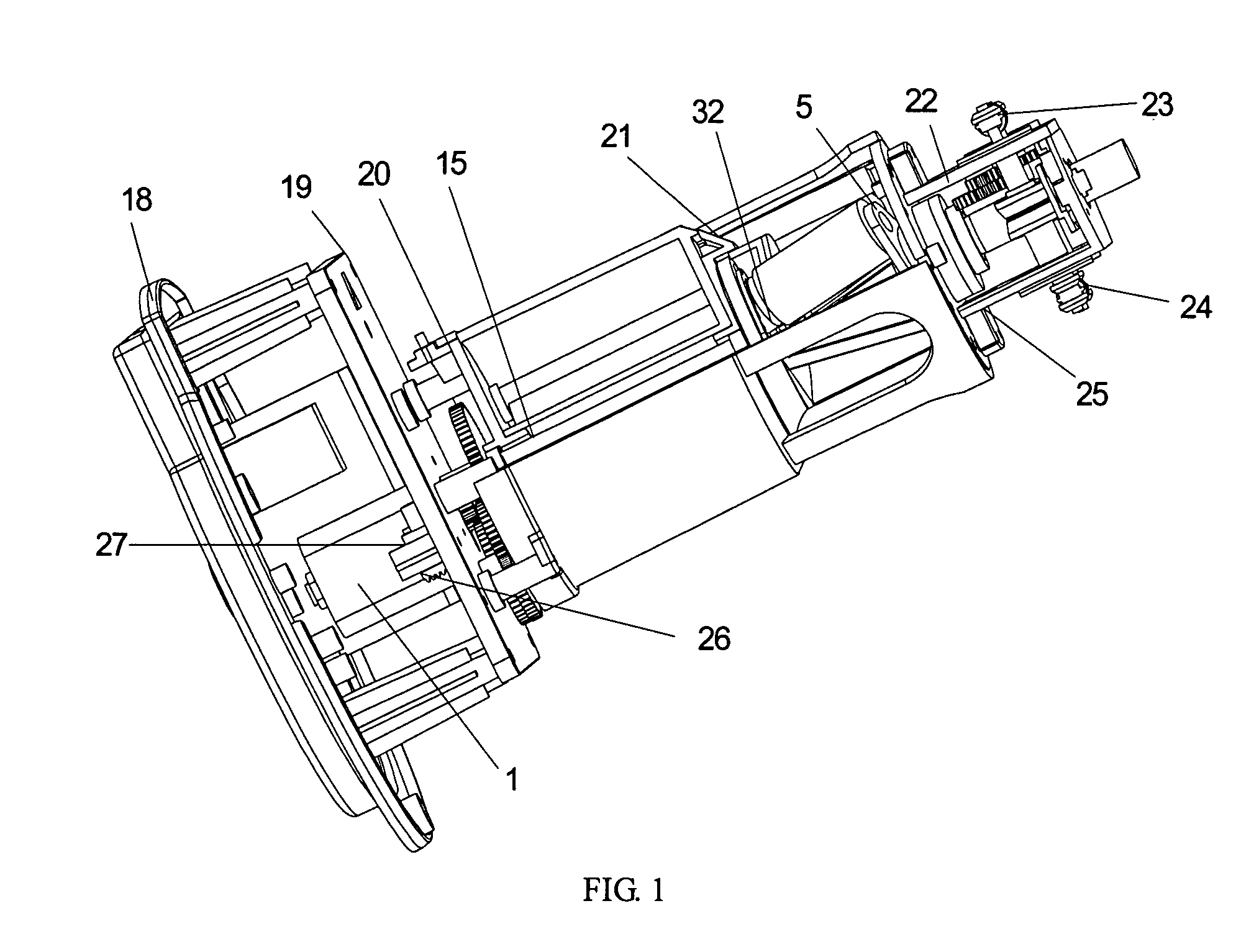

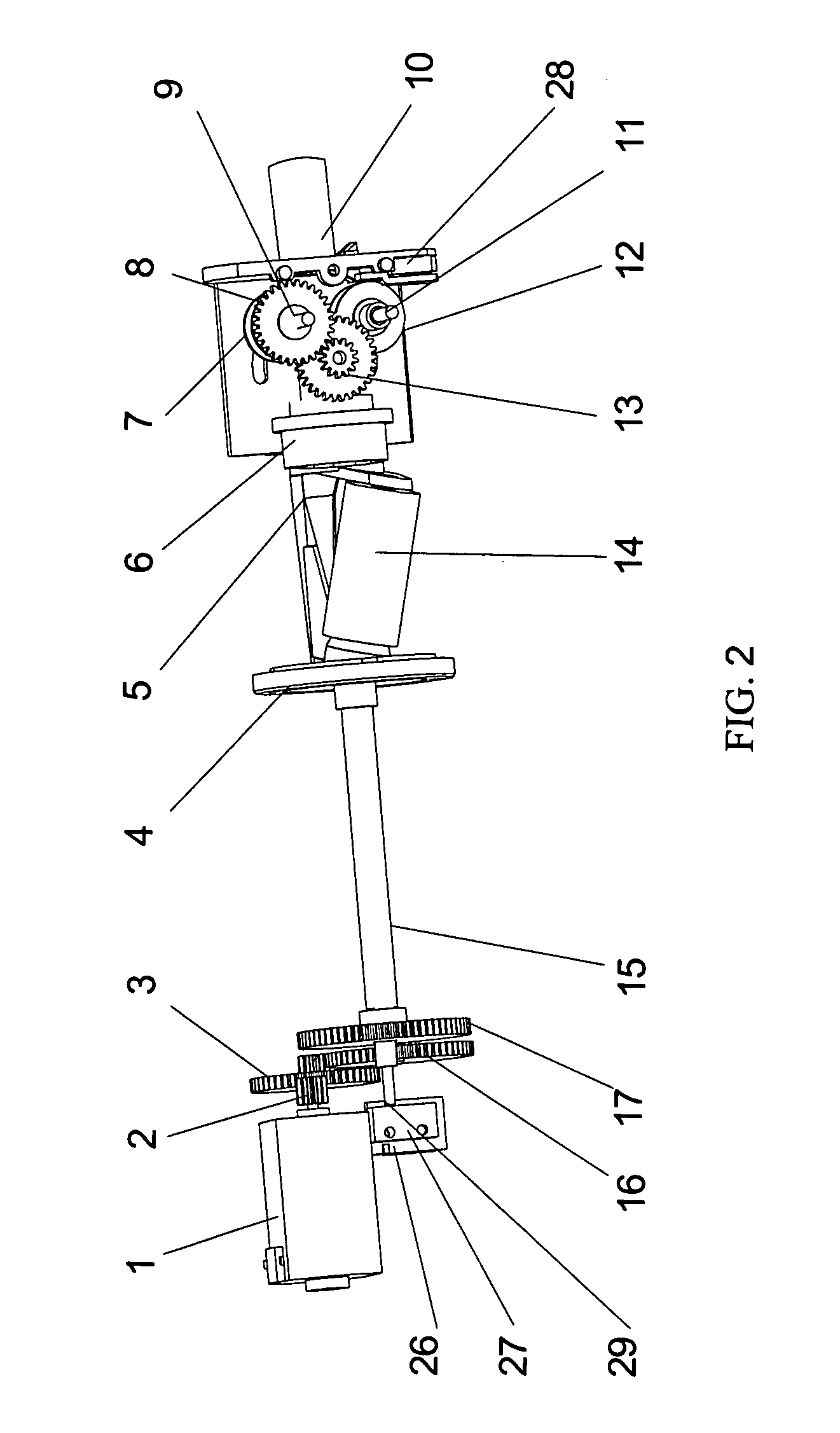

[0008]In one aspect of the present invention, an improved electric pencil sharpener is provided includes a motor, a transmission subassembly driven by the motor, a cutter subassembly driven by the transmission subassembly, a feeding subassembly driven by the cutter subassembly and at least one resilient adjusting means. The feeding subassembly includes a pair of feeding rollers movablely supported on two brackets arranged in parallel position, defining a feeding space therebetween. The at least one resilient means connects the two feeding rollers and is capable of automatically adjusting the interval between the two feeding rollers so as to conveniently sharpen pencils with different diameter.

[0009]In another aspect of the present invention, an improved electric pencil sharpener is disclosed engaging one resilient adjusting means, connecting the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com