Longitudinal feed self-adaptation device for steel rail milling and grinding machine

A technology for rail milling and grinding vehicles and longitudinal feeding, which is applied in the direction of grinding drive devices, grinding machine parts, grinding/polishing equipment, etc., which can solve the problems of grinding wheel wear feedback adjustment, etc., to improve feeding accuracy and safety performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

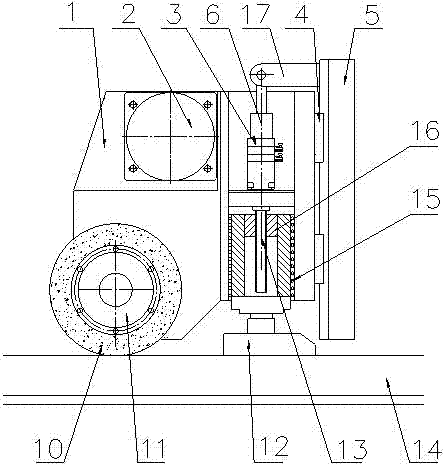

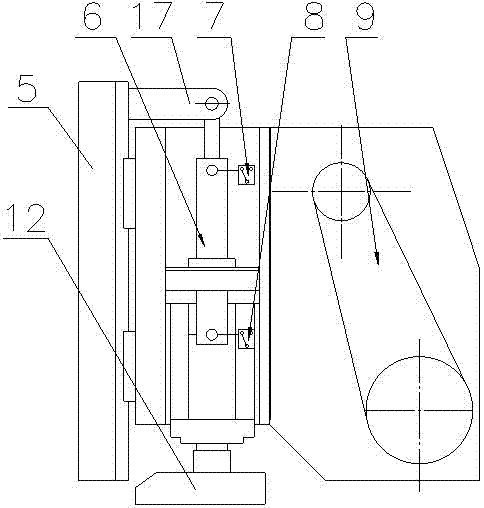

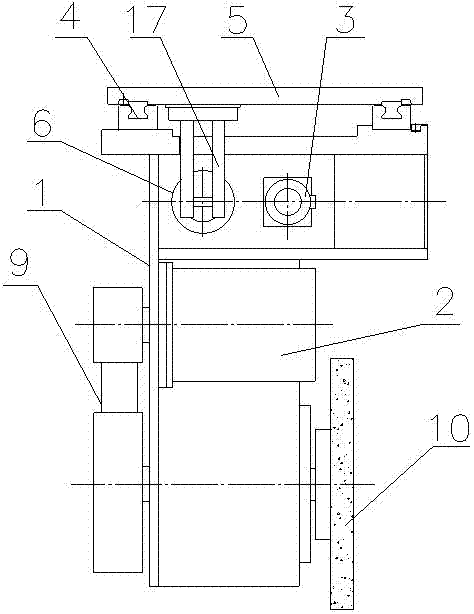

[0024] join in figure 1 , figure 2 and image 3 , rail milling car longitudinal feed self-adaptive device, including support frame 5, machine body 1, grinding wheel 10 and positioning shoe 12, support frame 5 is fixed on the rail milling car, is provided with the straight line guide rail 4 of vertical direction on it, The body 1 is installed on the linear guide rail 4 of the support frame through a guide groove provided on one side thereof, and a crossbeam 17 is arranged above the support frame 5, and one end of the vertical oil cylinder 6 is fixed on the crossbeam 17, and the other end is fixed on the body 1 And drive the body 1 to move up and down along the linear guide rail 4 on the support frame 5 . The upper cavity and the lower cavity of the vertical oil cylinder 6 are respectively provided with pressure sensors, and the upper cavity pressure sensor and the lower cavity pressure sensor are electrically connected with the servo motor 3 respectively. The body 1 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com