Device for feeding self-adhesive or "pressure sensitive" labels to a labelling machine

A labeling machine, pressure-sensitive technology, used in the field of devices for feeding self-adhesive or "pressure-sensitive" labels to labeling machines, capable of solving sudden slippage, sliding on motor-driven rollers instead of with motor-driven rollers Problems such as moving in one piece, rough cleaning operation, vibration of supports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

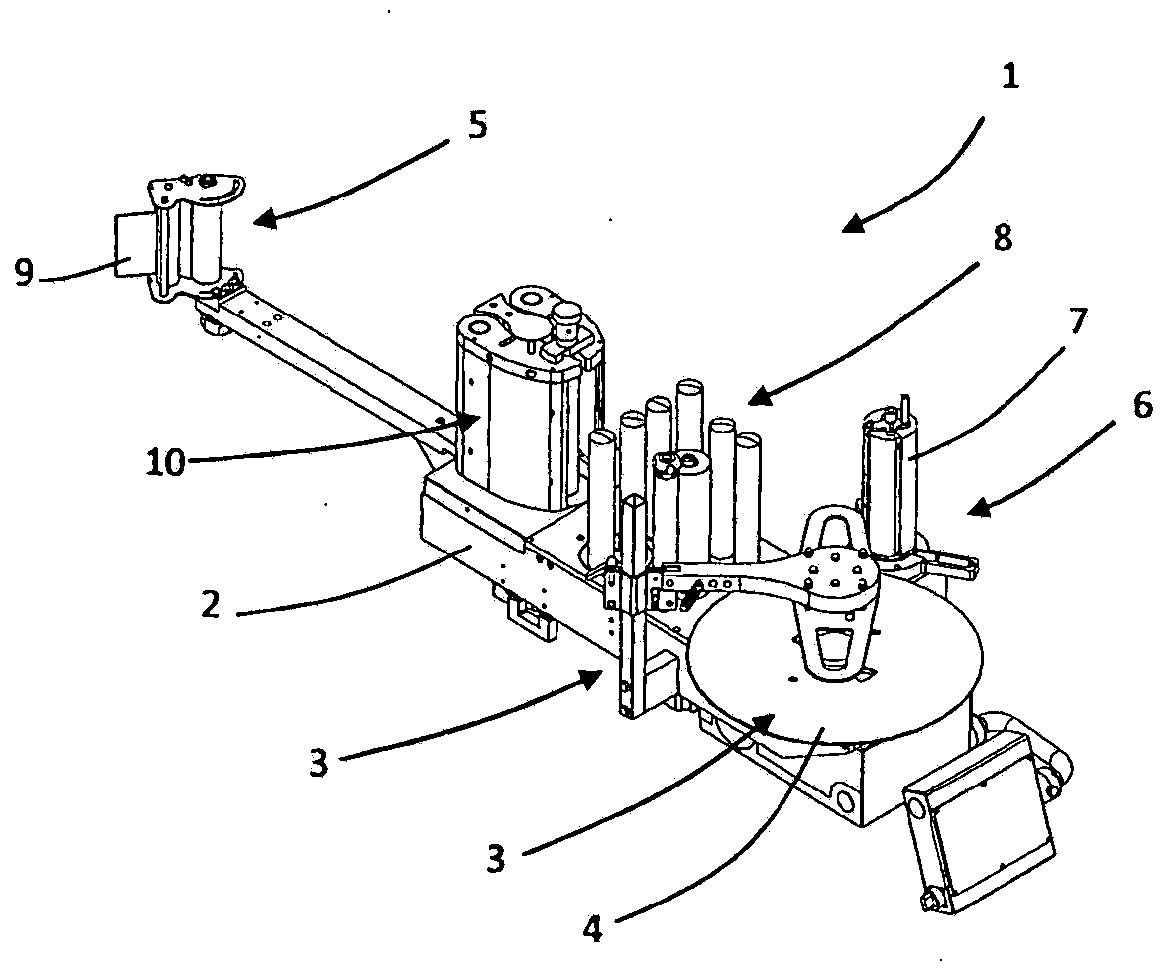

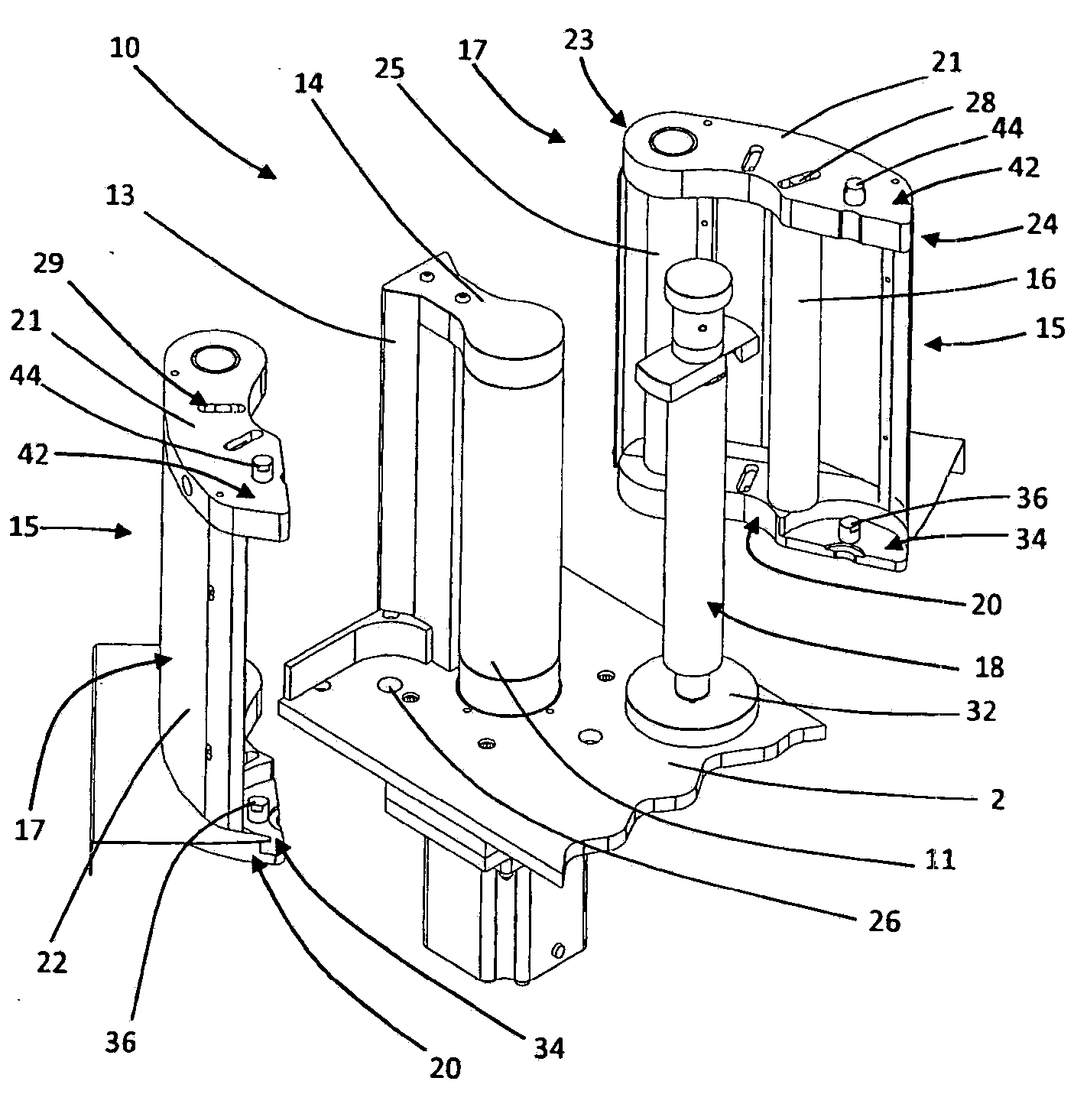

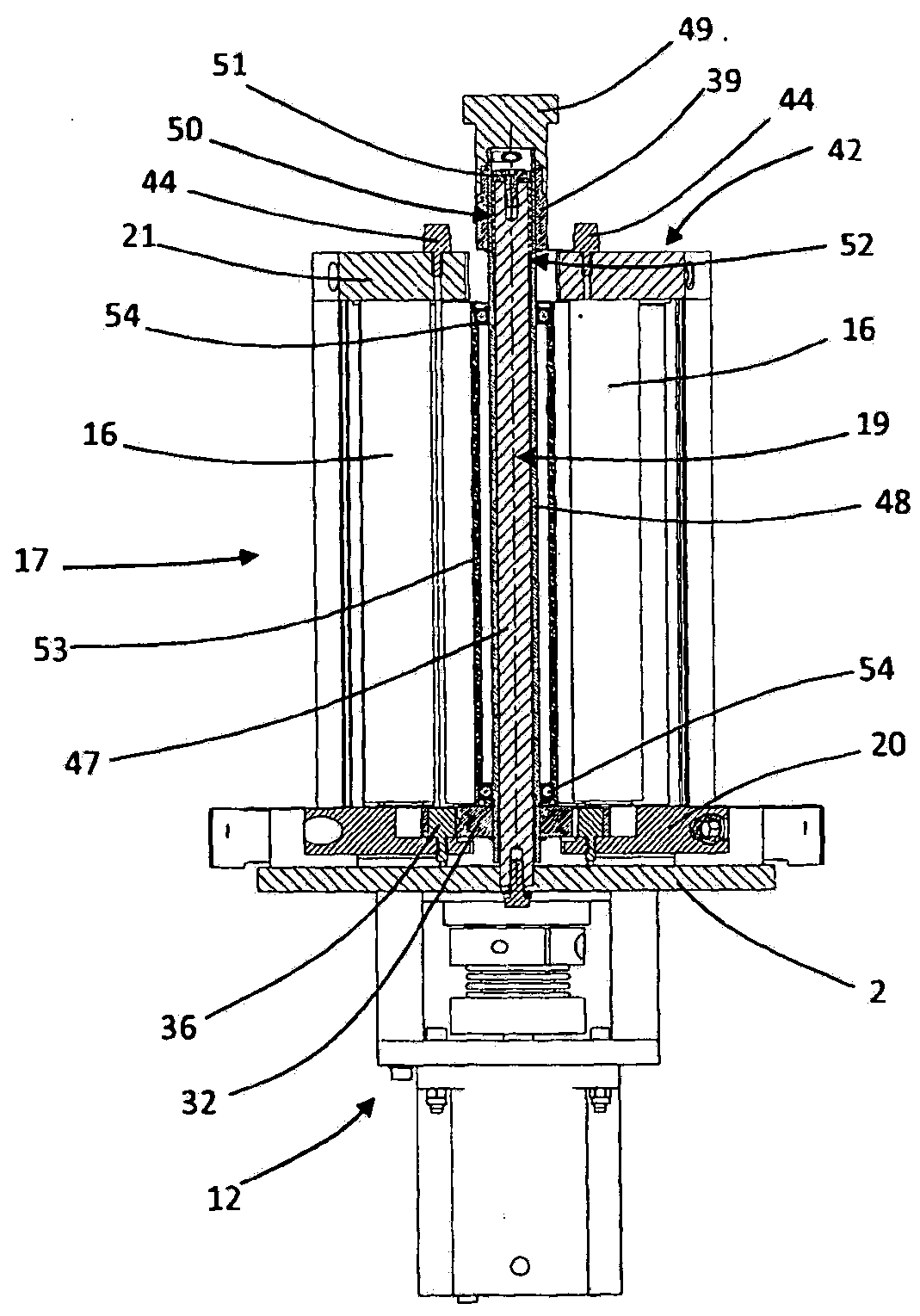

[0033] With reference to the drawings, numeral 1 generally designates a device for feeding self-adhesive or "pressure sensitive" labels to a labeling machine according to the invention.

[0034] The device 1 according to the invention comprises a frame 2 which can be coupled to a labeling machine and / or can rest on the ground, eg by means of suitable supports (not shown). The frame 2 is in fact advantageously arranged to allow the device 1 to be integrated into a labeling device and in particular to allow the device 1 to be connected and / or positioned close to the labeling machine.

[0035]The device 1 also comprises support means 3 mounted on the frame 2 in order to support the web roll for unwinding during operation. In a known manner, a roll is formed by winding a web on itself (or at least around a winding element), provided with self-adhesive or "pressure sensitive" labels removably attached to the web. In the embodiment shown, the support means 3 comprise a support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com