Micro-motion locking screw

A technology for locking screws and screws, which is applied in the direction of fixers, internal bone synthesis, fastening devices, etc. It can solve problems such as poor connection reliability, inability to pressurize the fracture site, and difficulty in connecting and assembling the tapered screw shaft and the threaded sleeve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

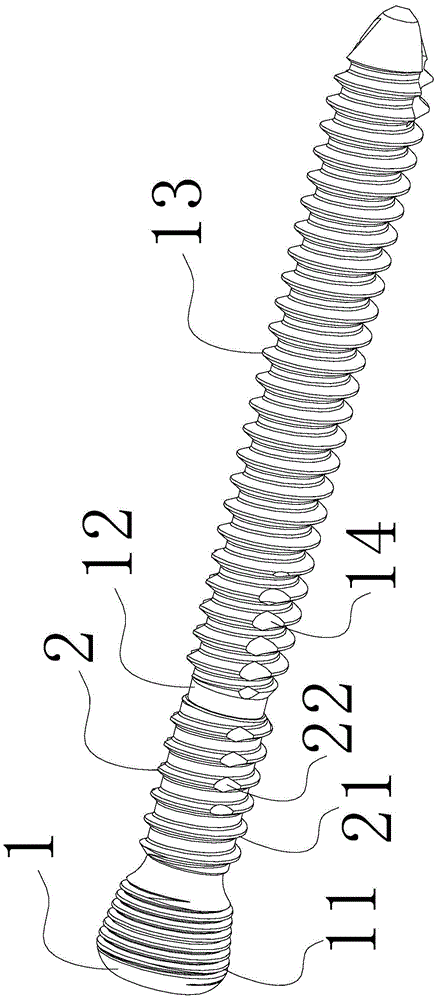

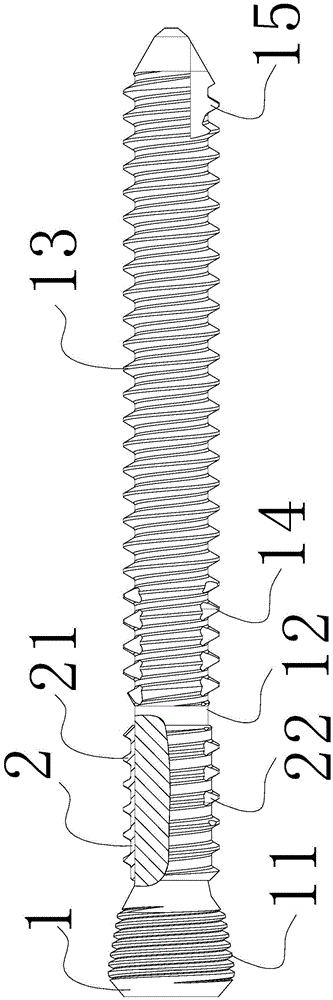

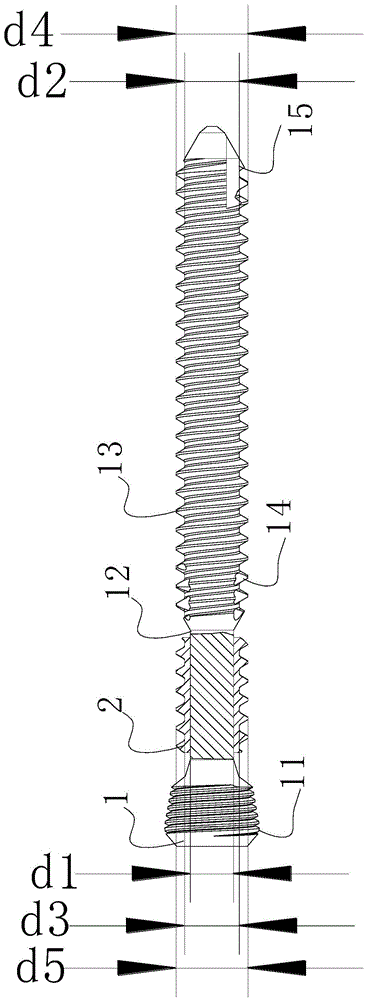

[0030] See figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 , a micro-motion locking screw with a diameter of 5.5*50, the screw body 1 is made of stainless steel, the screw sleeve 2 is made of polylactic acid material, and the screw sleeve 2 is directly formed and fixed on the screw body 1 by injection molding. The screw body is composed of a locking thread 11, a connecting rod 12, a screw back self-tapping groove 14, a bone thread 13, and a screw-in self-tapping groove 15 which are sequentially connected. The bone thread 13 is a cortical bone thread. The diameter d1 of the connecting rod 12 on the screw body is equal to the minor thread diameter d2 of the bone thread 13 which is 4.0, the major thread diameter d4 of the bone thread 13 is 5.0, and the pitch is 1.3. The minor thread diameter d3 of the screw sleeve 2 is 4.5, the major thread diameter d5 is equal to the major thread diameter d4 of the bone thread 13 , and the outer surface of the screw sleeve 2 is pro...

Embodiment 2

[0032] See image 3 , a micro-motion locking screw with a diameter of 5.5*50, the screw body 1 is made of titanium alloy material, the screw sleeve 2 is made of polylactic acid material, and the screw sleeve 2 is directly formed and fixed on the screw body 1 by injection molding. The screw body is composed of a locking thread 11, a connecting rod 12, a screw back self-tapping groove 14, a bone thread 13, and a screw-in self-tapping groove 15 which are sequentially connected. The bone thread 13 is a cortical bone thread. The diameter d1 of the connecting rod 12 on the screw body is 3.5, the major thread diameter d4 of the bone thread 13 is 5.0, the minor thread diameter d2 is 4.0, and the pitch is 1.3. The small thread diameter d3 of the screw sleeve 2 is equal to the small thread diameter d2 of the bone thread 13, the major thread diameter d5 is equal to the major thread diameter d4 of the bone thread 13, and the outer surface of the screw sleeve 2 has no self-tapping groove....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com