Drilling machine provided with automatic feeding device

A technology of automatic feeding and pushing device, applied in metal processing and other directions, can solve the problems that the drilling machine cannot realize automatic feeding, low drilling efficiency, etc., to improve the clamping efficiency and drilling efficiency, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

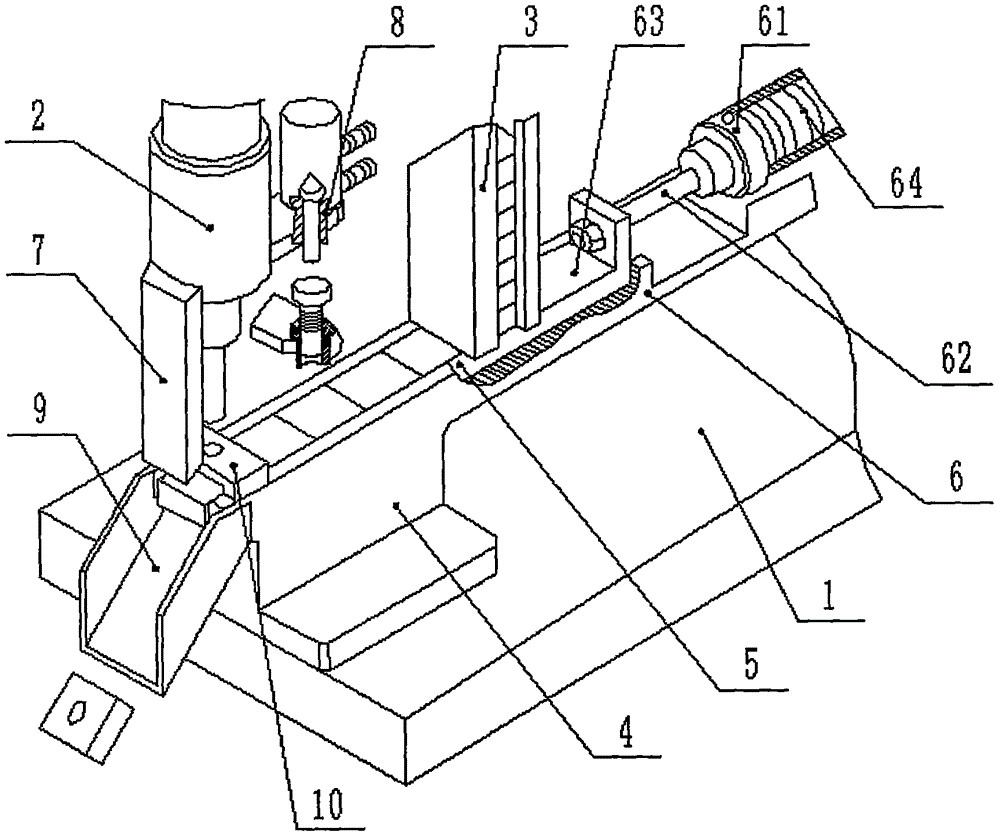

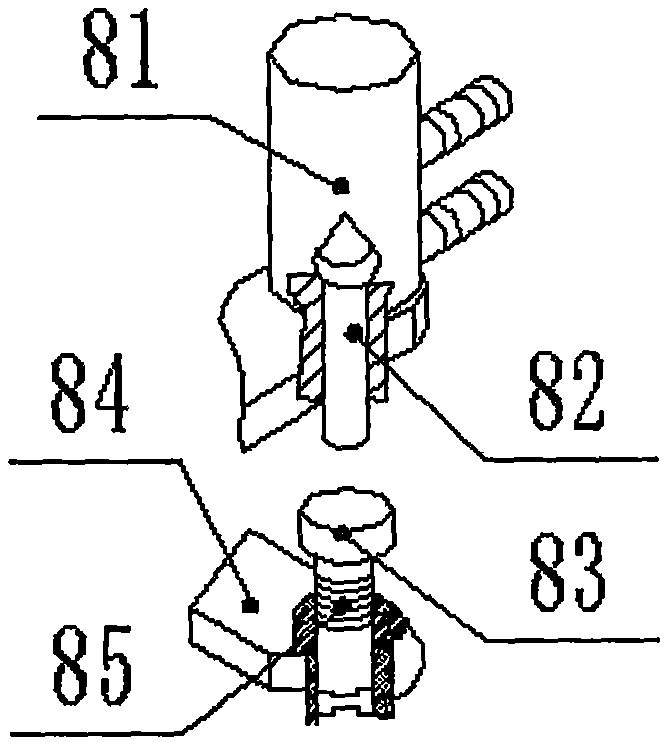

[0016] Such as figure 1 , figure 2 As shown, a drilling machine with an automatic feeding device includes a workbench 1 and a drilling machine spindle 2. One side of the drilling machine spindle 2 is fixedly provided with a material storage tank 3, and a feeder is fixedly installed on the workbench 1 below the material storage tank 3. The base 4 and the feeding base 4 are preset with a feeding guide groove 5, the outlet of the material storage tank 3 is facing the feeding guide groove 5, and one side of the feeding guide groove 5 extends to the directly below the drilling machine main shaft 2. The other side of the material guide groove 5 is equipped with a material pushing device 6, and the workpiece stopper 7 is fixedly arranged on the drilling machine main shaft 2, and the working stopper can slide up and down along the outer surface of the drilling machine main shaft 2, and the workpiece stopper 7 is positioned at the vertical position after falling vertically. 5 ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com