Speed planning method of cutting machine

A speed planning and cutting machine technology, applied in the direction of instruments, digital control, control/regulation systems, etc., can solve the problems of slow running speed, achieve the effect of improving production efficiency, avoiding over-cutting, and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

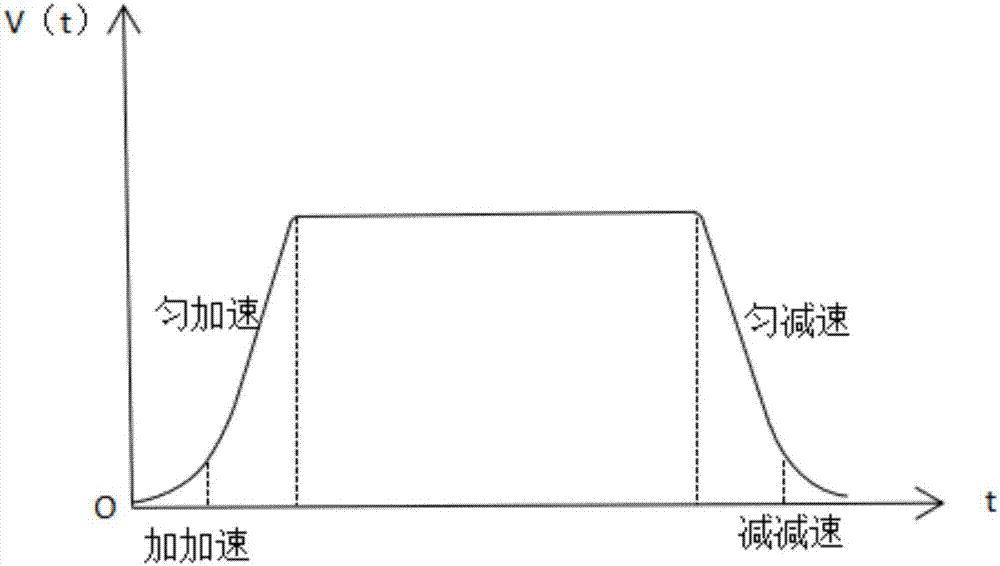

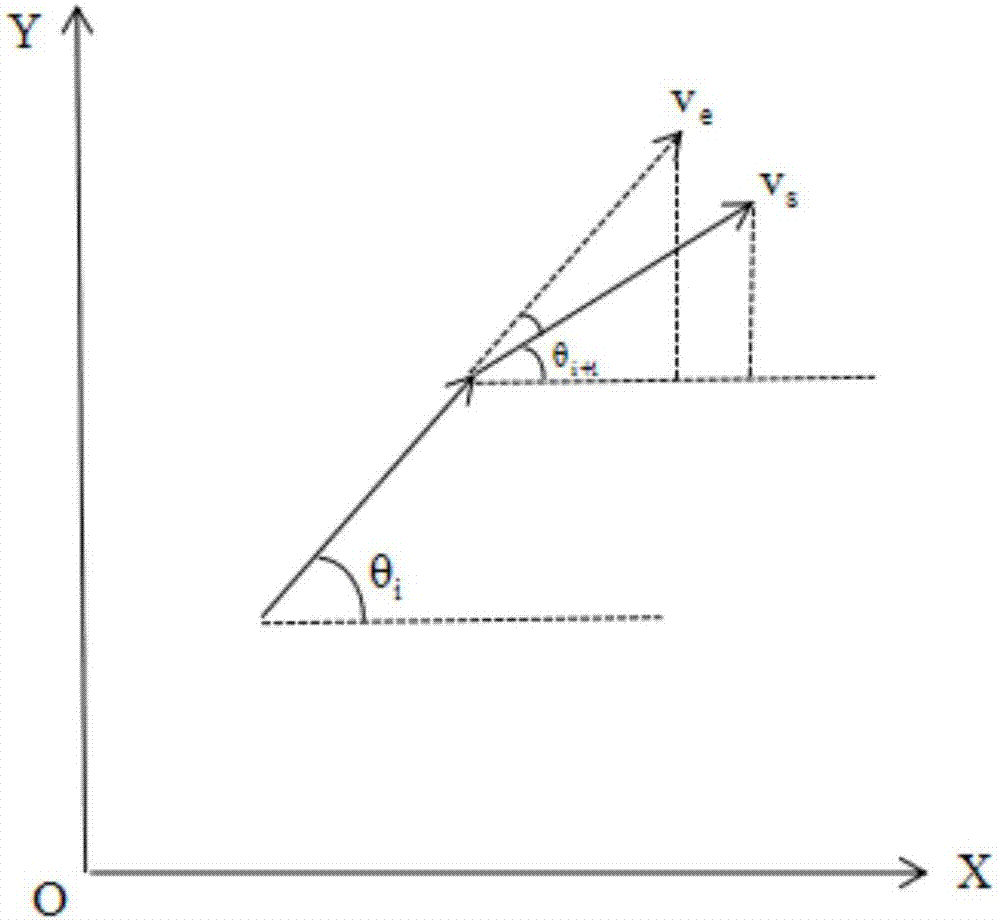

[0022] refer to figure 1 with figure 2 , a speed planning method for a cutting machine, comprising the following steps:

[0023] 1) Adopt the S-type five-stage acceleration and deceleration control method to determine the corresponding ladder step length table

[0024] The acceleration and deceleration control of this system adopts the S-type five-stage speed control method, which is divided into acceleration and acceleration sections, uniform acceleration sections, uniform speed sections, uniform deceleration sections, and deceleration and deceleration sections. Compared with the seven-segment standard S-shaped speed curve, the deceleration and acceleration segments and acceleration and deceleration segments are omitted. This control method can start smoothly and accelerate to the maximum speed in the shortest time, thereby reducing the acceleration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com