A method for stably controlling the slewing mechanism of a tower crane

A technology for tower cranes and slewing mechanisms, applied in cranes, load hanging components, transportation and packaging, etc., can solve problems such as unreliability, and achieve the effects of short acceleration and deceleration time, small maintenance workload and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

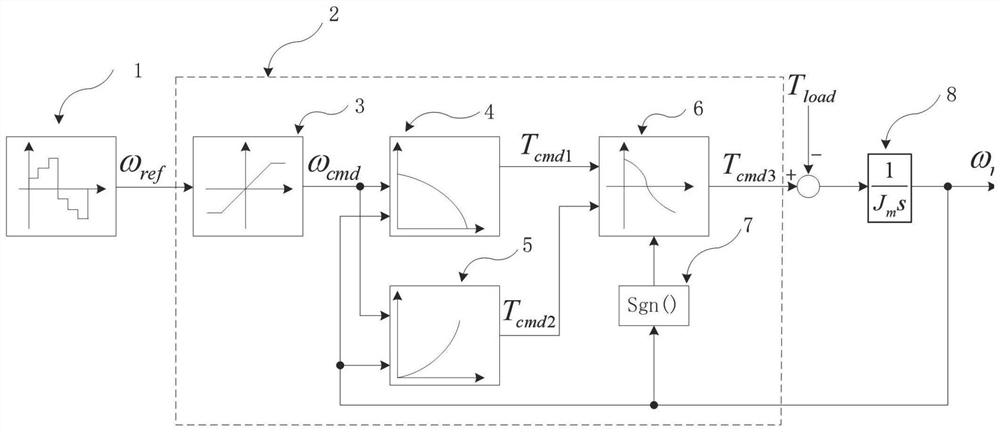

[0034] Driven by a frequency converter, an ordinary variable frequency motor has the ability to output constant torque within the range from zero speed to rated speed when vector control is used, that is, it can output less than the maximum speed within the range from zero speed to rated speed. In other words, the ordinary variable frequency motor at this time can be regarded as a controllable torque generator. When the controllable torque generator can simulate the mechanical characteristics of the torque motor plus the eddy current brake, the ordinary variable frequency motor can control the slewing mechanism of the tower crane to achieve the control effect of RCV.

[0035] Depend on figure 1 As shown, what dashed line frame 2 represents is the concrete content of the present invention, and gear position signal generator 1 produces the gear position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com