Thin film transistor and manufacturing method, array substrate and display device

A technology for thin film transistors and a manufacturing method, applied in the field of display processing, can solve the problems of under-etching or over-etching of contact holes, adverse effects of thin-film transistors, and difficulty in mastering the etching process, so as to prevent etching to the active layer and prevent over-etching. The effect of engraving and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

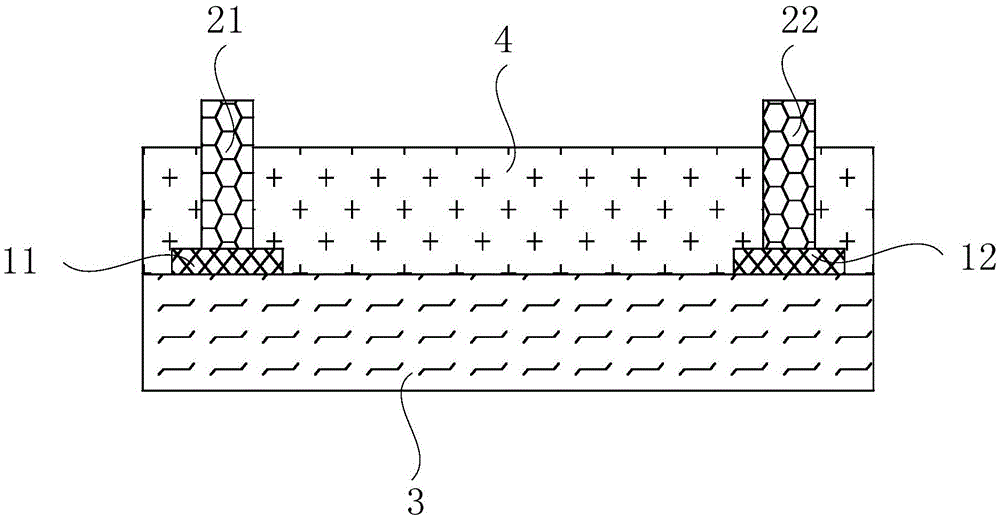

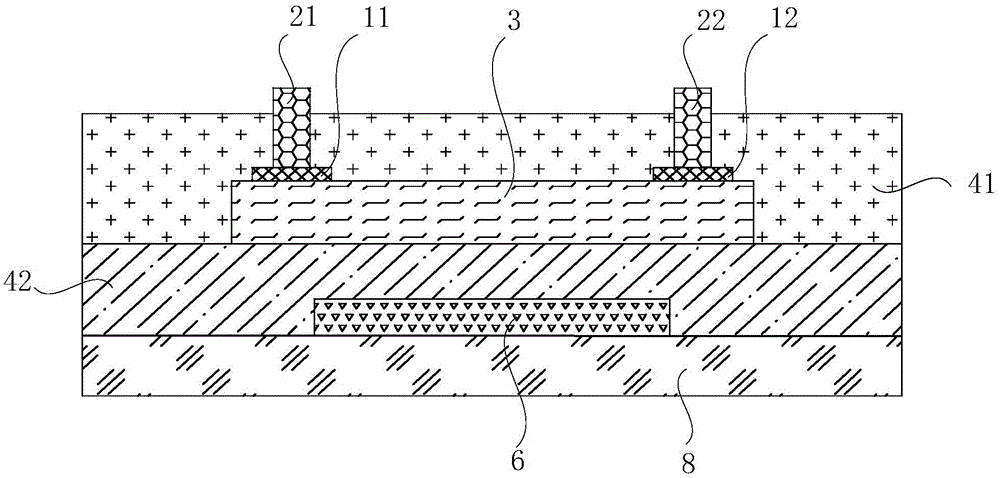

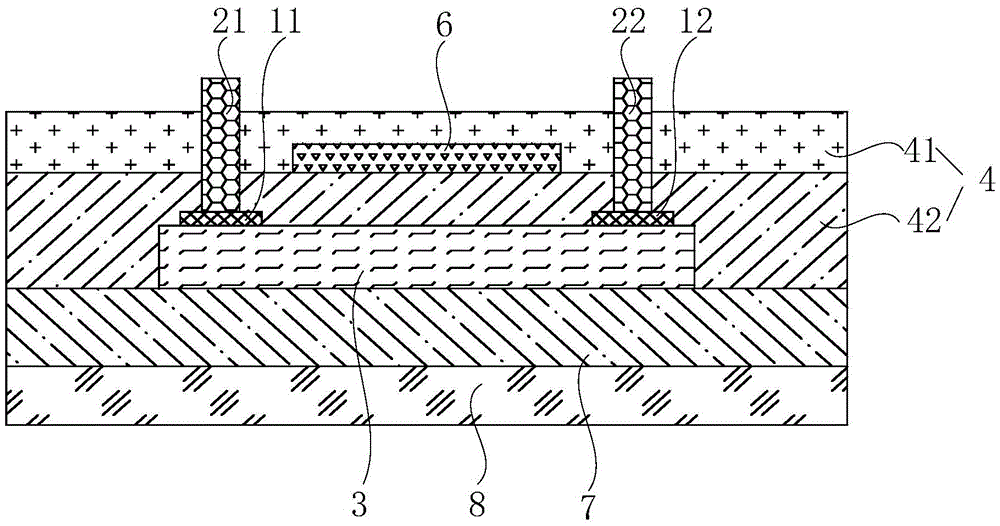

[0054] An embodiment of the present invention provides a thin film transistor, see Figure 1-Figure 6 , the thin film transistor includes:

[0055] The first etching barrier layer 11, the second etching barrier layer 12, the source electrode 21, the drain electrode 22, the insulating layer 4 and the active layer 3;

[0056] The first etch barrier layer 11 and the second etch barrier layer 12 are disposed on the active layer 3, the insulating layer 4 is disposed on the active layer 3, the first etch barrier layer 11 and the second etch barrier layer 12, The insulating layer 4 is provided with a first contact hole 51 and a second contact hole 52;

[0057] The source electrode 21 is electrically connected to the active layer 3 through the first contact hole 51, and the drain electrode 22 is electrically connected to the active layer 3 through the second contact hole 52;

[0058] The first etch stop layer 11 is located between the active layer 3 and the source 21 , and the secon...

Embodiment 2

[0089] On the other hand, the embodiment of the present invention further provides an array substrate, and the array substrate includes the thin film transistor described in the first embodiment.

[0090] The array substrate provided in this embodiment includes the thin film transistor described in Embodiment 1. The thin film transistor in Embodiment 1 solves the problem of under-etching or over-etching in the contact hole etching process, and improves the yield of thin film transistors. At the same time, the first embodiment The material of the first etch barrier layer 11 is the same as the material of the first layer in the source electrode 21, and the first etch barrier layer 11 is connected to the material of the first layer in the source electrode 21, and the material of the first etch barrier layer 11 is the same as that of the first layer of the source electrode 21. The material of the second etch barrier layer 12 is the same, and the structure and material of the source...

Embodiment 3

[0092] On the other hand, the embodiment of the present invention further provides a display device, the display device includes the array substrate described in the second embodiment.

[0093] The display device provided in this embodiment includes the array substrate of the second embodiment. The array substrate of the second embodiment solves the problem of under-etching or over-etching in the contact hole etching process, and improves the yield of the array substrate. At the same time, the first engraving The material of the etch barrier layer 11 is the same as that of the first layer in the source electrode 21, and the first etch barrier layer 11 is connected with the material of the first layer in the source electrode 21, and the material of the first etch barrier layer 11 is the same as that of the second layer. The material of the etch barrier layer 12 is the same, and the structure and material of the source electrode 21 and the drain electrode 22 are all the same, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com