Method for generating optimal straight-line enveloping surface of free-form surface blade

A curved surface and free technology, applied in milling machine equipment details, milling machine equipment, digital control, etc., can solve problems such as large margin difference, overcut, and affecting the surface processing quality of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

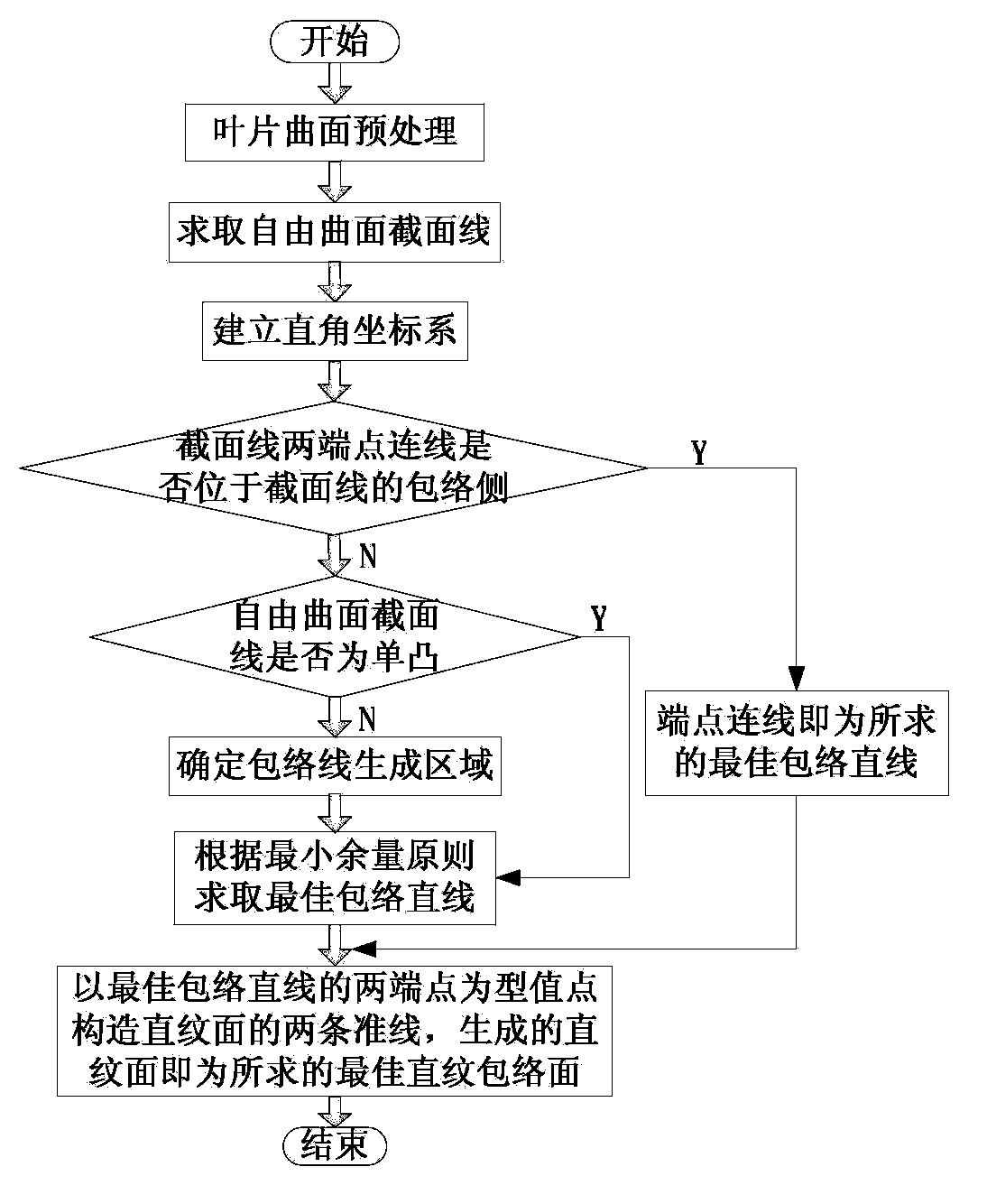

[0033] This embodiment provides a method for generating an optimal ruled envelope surface of a free-form surface blade for the four-coordinate plunge-milling rough machining of the blade profile of the impeller blade disc parts.

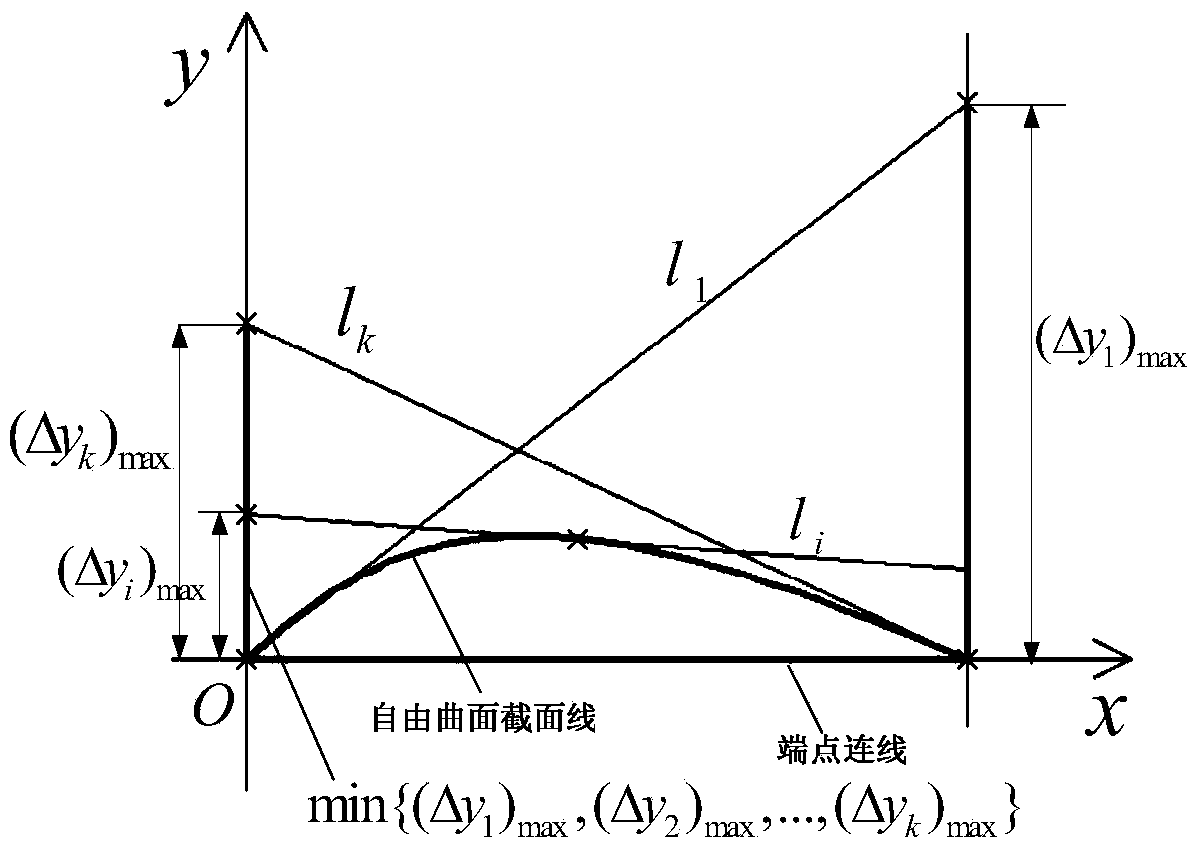

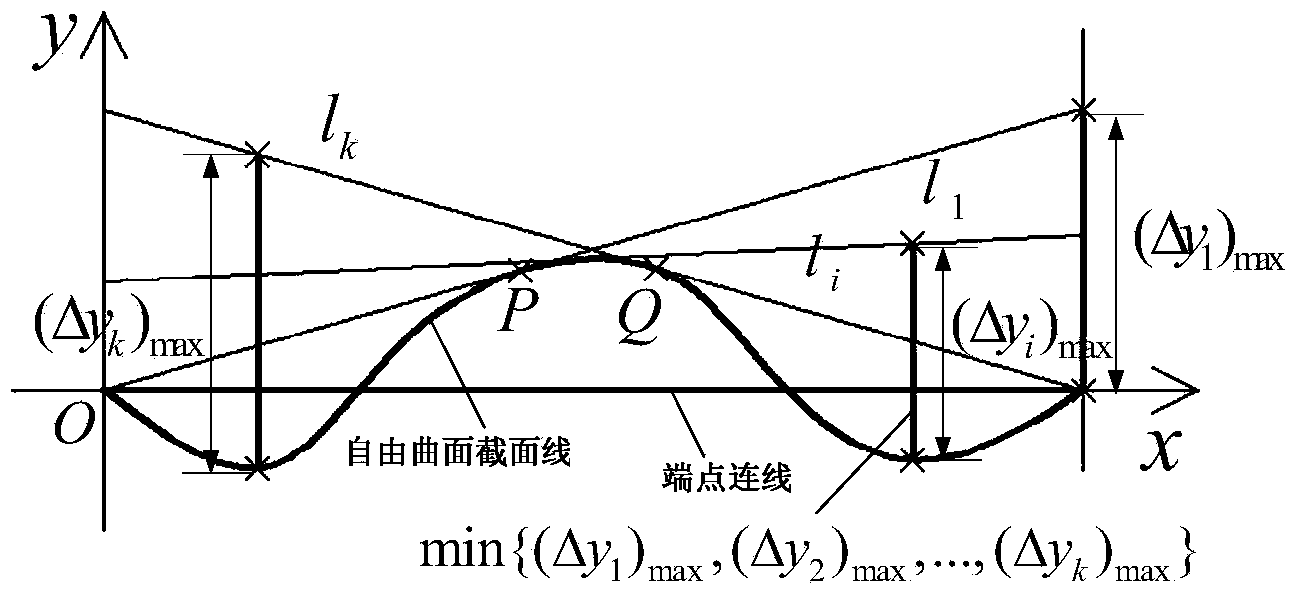

[0034] refer to figure 1 , figure 2 , using the best ruled envelope surface generation method for free-form surface blades to generate the best ruled envelope surface for a certain type of aero-engine open-type blisk blade. The open overall blade disc includes the back side of the blade 1, the blade pot surface 2, the hub surface 3, the back rafter 4, the front rafter 5, the blade root line 6, and the blade tip line 7, and the relevant parameters are: the diameter of the blade disc is 550 mm, the blade The length is 88mm and the cutter diameter is 12mm. The optimal ruled envelope generation process of its leaf back 1 includes the following steps:

[0035] The first step is to preprocess the leaf back 1: select the leaf back 1 in the passage area,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com