Wheel rotary cutting method of rail wagon

A railway freight car and wheel technology, applied in the field of railway freight car wheel turning, can solve the problems of scrapped wheels, improper selection and processing, and reduced service life of wheel sets, so as to avoid excessive cutting, reduce repair costs and improve repair rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A method for turning wheels of railway wagons, comprising the following steps:

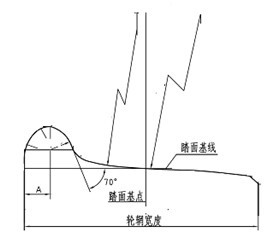

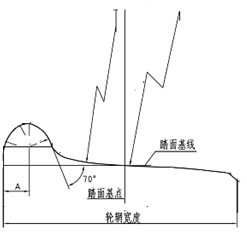

[0025] Step 1. For the wheel set that needs to be economically cut, use laser to measure and scan the shape of the wheel set tread from the 1:8 straight line to the vertex of the rim or the entire rim to obtain the profile curve of the wheel set tread, so as to calculate the wear wheel The thickness of the rim and the size of the wheel diameter; the specific method for calculating the thickness of the worn rim and the size of the wheel diameter is: the laser measures the tread surface of the wheel set to obtain the coordinates of the discrete point data, and the orthogonal polynomial curve fitting is performed on these discrete point data by mathematical methods. Filter out the non-points in the measurement to get a smooth wheel-tread profile curve; get the Y-coordinate value of the X-axis -70 coordinate from this smooth wheel-tread profile curve, which is the current wheel diameter size; an...

Embodiment 2

[0030] Process the standard curve with the smallest processing amount at the circumference of the wheel diameter, and the specific steps for calculating the processing amount are as follows:

[0031] Step 2c, obtain the rim thickness of the current wheel set, the wear and peeling degree of the circumference of the wheel diameter, and the degree of black skin on the outer side of the wheel rim and the tread part according to the iron standard, and prevent damage to the machine tool due to the small amount of processing. Hard damage parameters;

[0032] Step 2d, according to the rim thickness of the current wheel set obtained in step 2c, the wear and peeling degree of the circumference of the wheel diameter, and the parameters of the degree of black skin allowed to be left on the outer side of the wheel rim and the tread part according to the iron standard, and to prevent due to the amount of processing When the hard damage parameters of the machine tool are small, select a stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com