Numerical control machining method of annular hiding groove in arc-shaped surface

A processing method and arc surface technology, which is applied in the field of numerical control machining of annular avoidance grooves in arc surfaces, can solve the problems of large processing range, easy folding knife, machine tool overtravel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

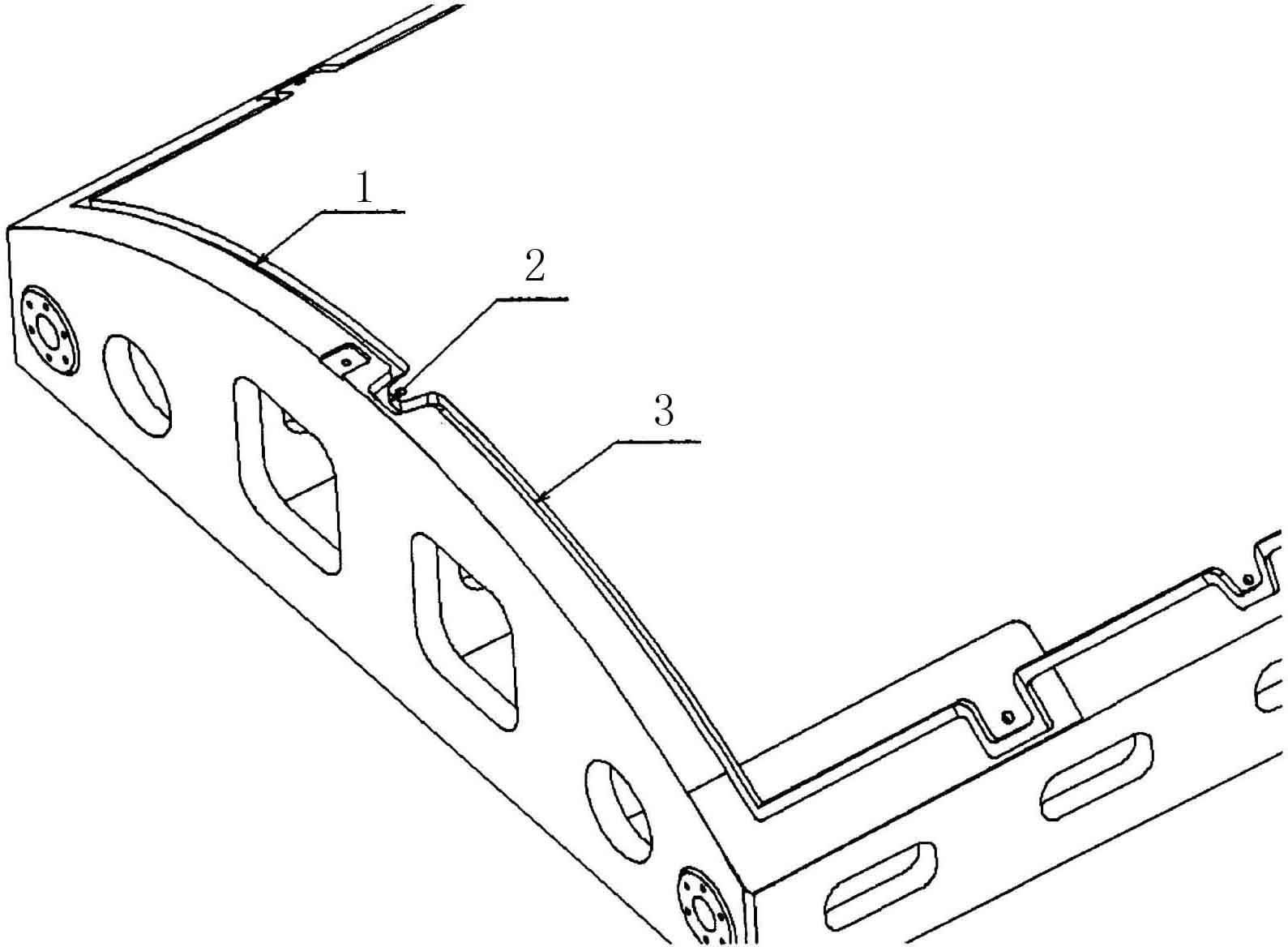

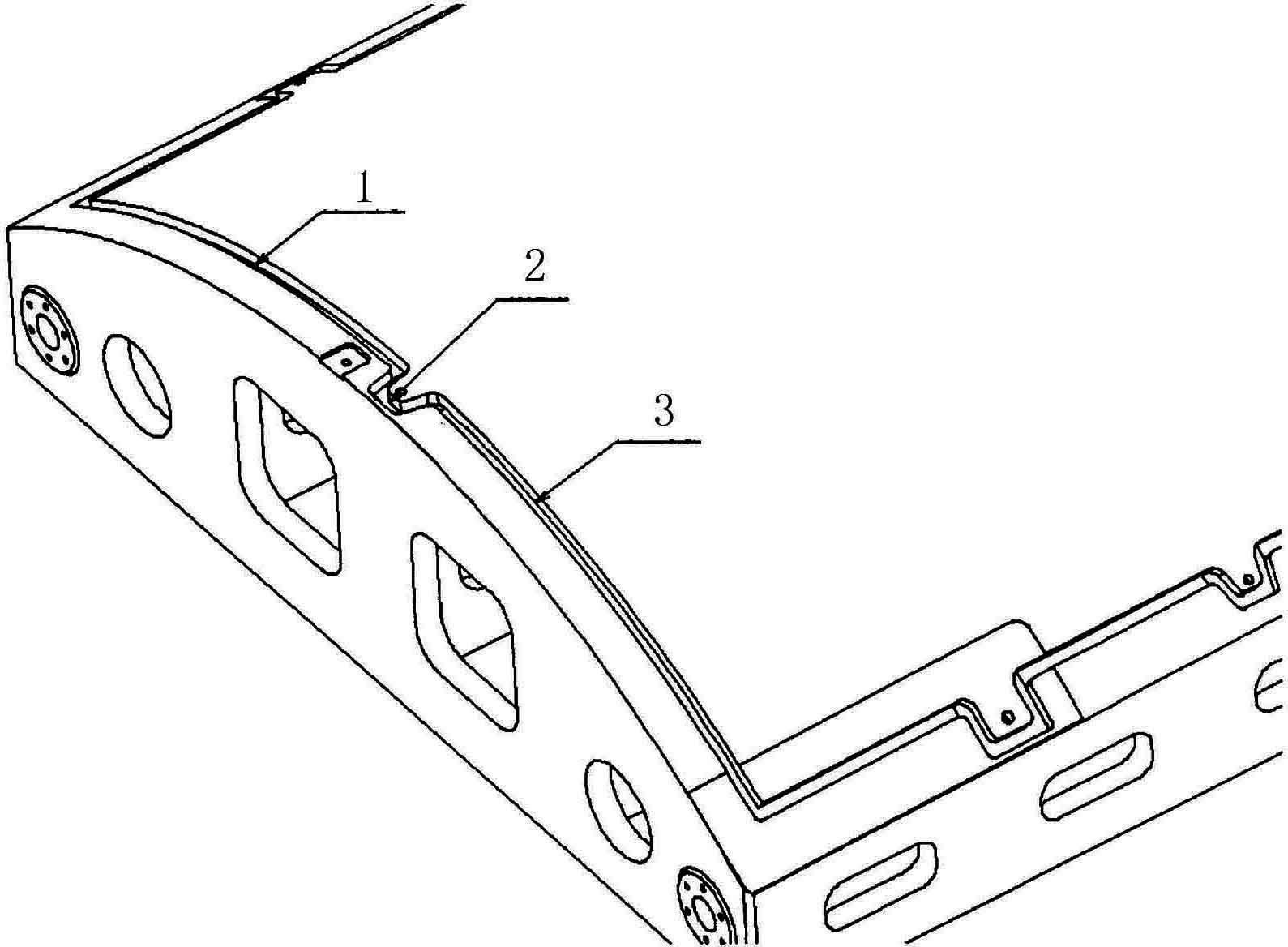

[0018] Such as figure 1 As shown, a numerical control machining method of an annular dodging groove in an arc surface includes the following steps:

[0019] 1) The curved surface is taken as a whole, that is, the avoidance groove is repaired. The meaning of sewing is to directly process a whole outer surface at one time without considering the size of the groove; all dimensions from rough milling to fine milling are in place, so that the overall processing of the part is more accurate. Smooth and smooth, there will be no sudden drop of the profile and the phenomenon of folding knives;

[0020] 2) Process the stitched dodging groove. Due to the large span of the annular dodging groove, the dodging groove is divided into two parts along the axis direction, and one part is processed by five-axis linkage layering, which can effectively solve the problem of overtravel. question;

[0021] 2.1) For the straight part of the avoidance groove, the thickness of each layer is 5mm, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com