Method for grinding installation angle of grinding wheel through inner roller path of ball nut and designing accurate profile

A technology for ball nuts and design methods, which is applied in the direction of grinding devices, grinding/polishing equipment, metal processing equipment, etc., and can solve the problem of affecting the machining quality and maximum length of machinable nuts, the non-normal truncation of ball nuts, and overcutting And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with drawings and embodiments.

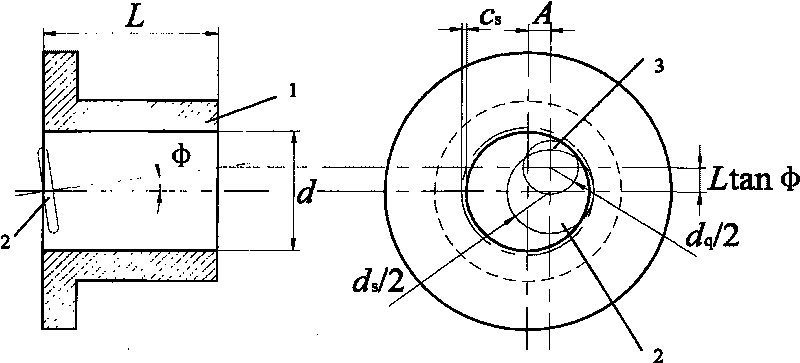

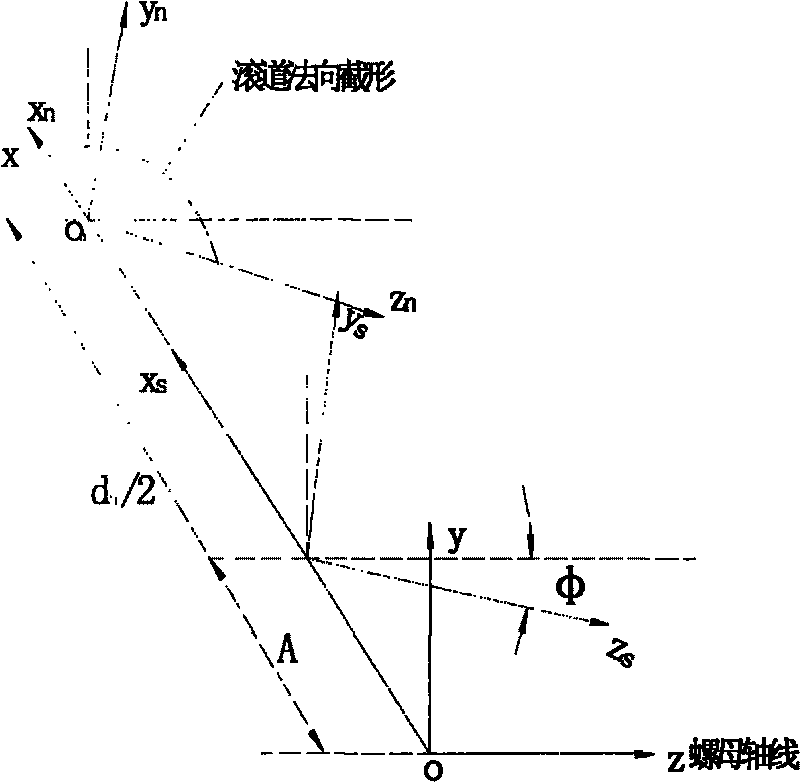

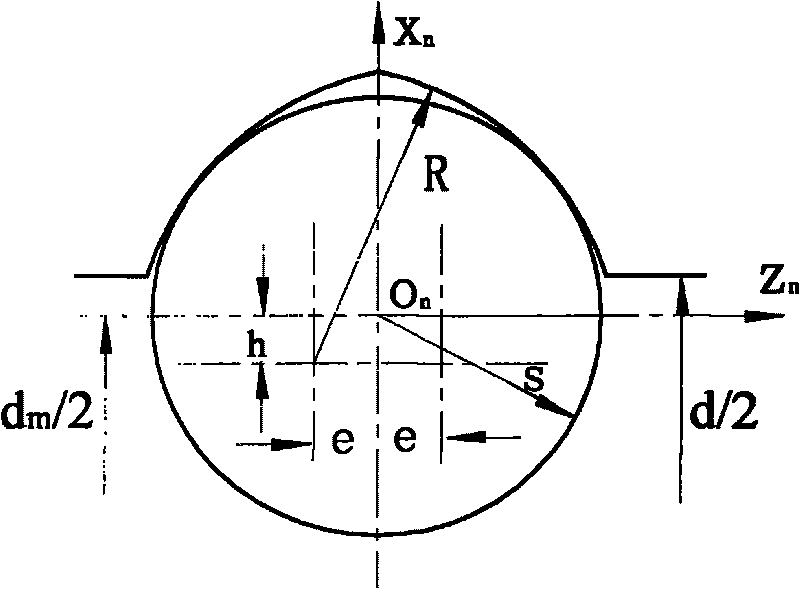

[0075] Known ball nut raceway normal sectional parameters: e--the eccentricity of the two arcs of the raceway; R--the radius of the raceway arc; h--the distance from the center of the raceway arc to the center of the ball; d -- Ball nut inner diameter; d m -- Ball center track diameter. Other related parameters are also known: P--ball nut lead; L--ball nut axial length; c s -- screw groove depth; d s -- diameter of grinding wheel; d q -- Diameter of grinding rod.

[0076] 1) Calculate the center distance

[0077] see figure 1 , when the double-arc section of a ball nut raceway and the length of the nut are given, and the required grinding wheel diameter d is determined according to the nut processing technology s and rod diameter d q Finally, calculate the center distance A between the grinding wheel and the nut. Calculate the center distance A between the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com