High-speed precise horizontal five-axis linkage aero-engine blade numerical control milling center

An aero-engine, five-axis linkage technology, applied in milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve problems such as poor overall rigidity, and achieve good compensation effect, good dynamic performance, and good dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

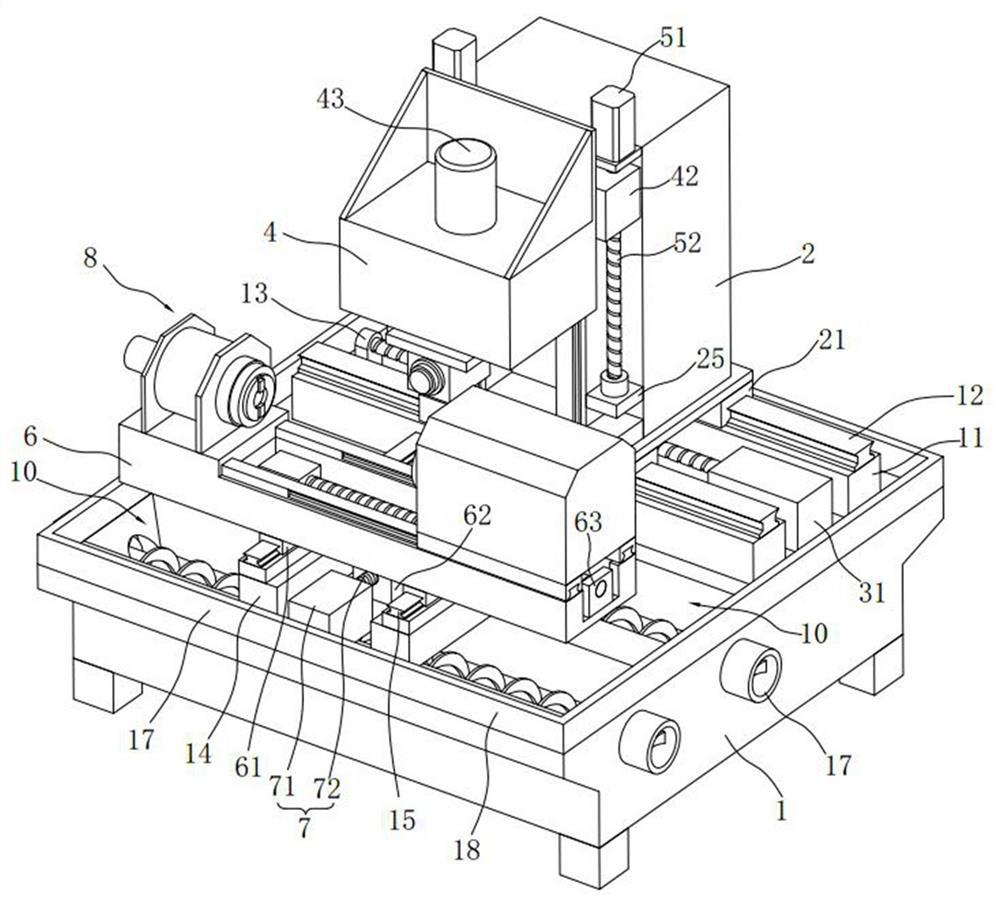

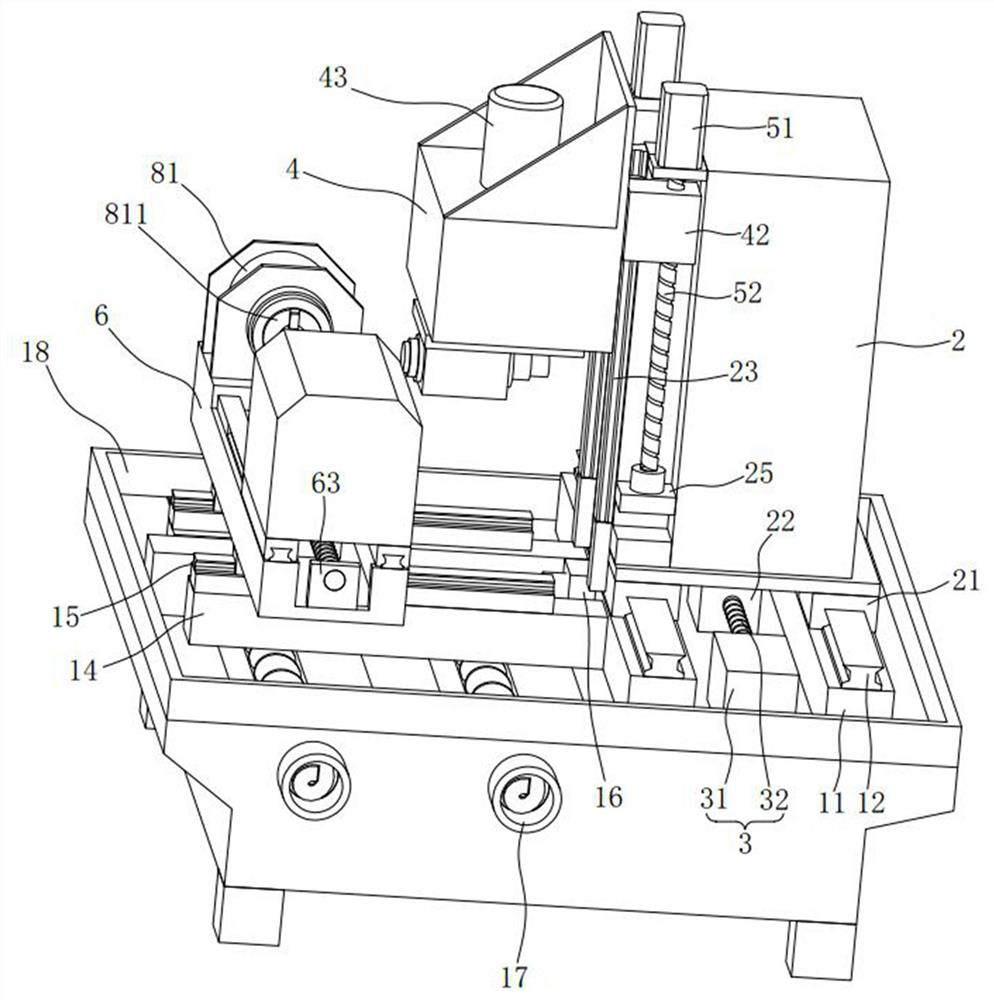

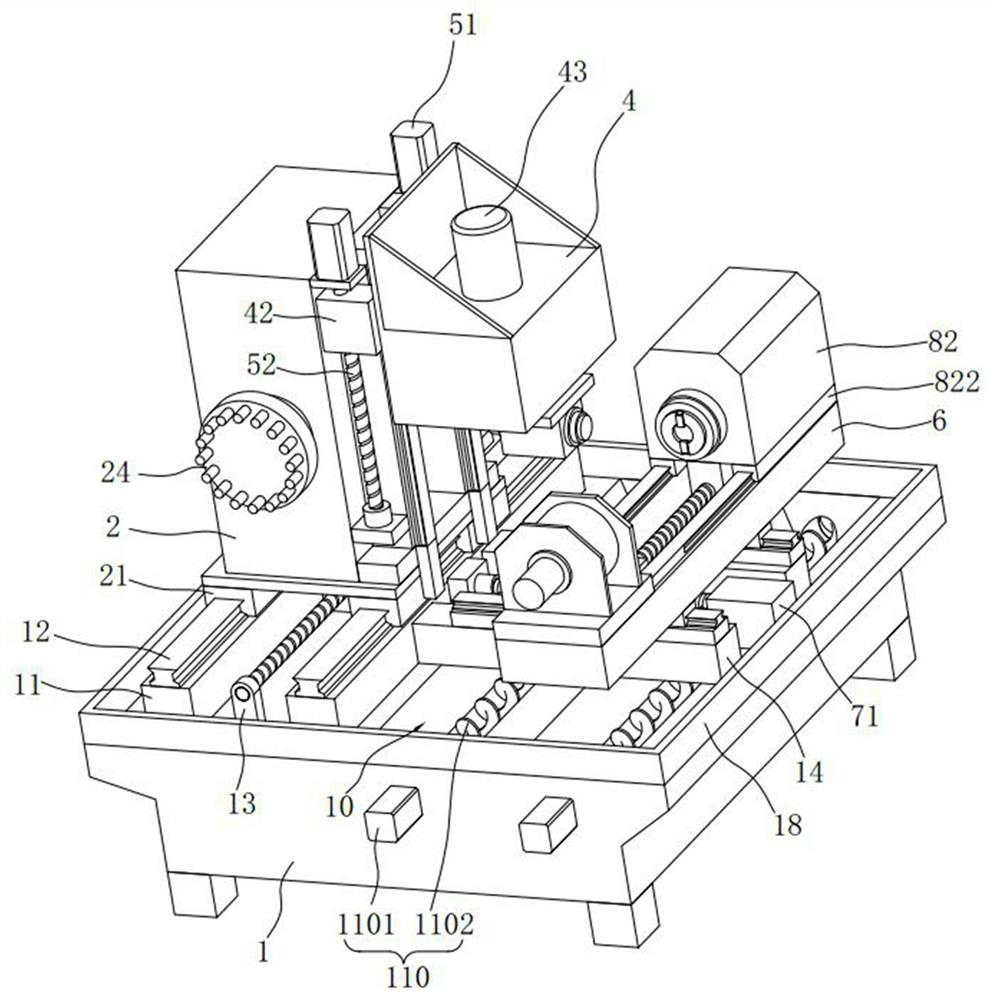

[0036] The following is attached Figure 1-6 The application is described in further detail.

[0037] The embodiment of the present application discloses a high-speed precision horizontal five-axis linkage aero-engine blade CNC milling center. refer to figure 1 , the horizontal five-axis linkage blade milling center includes a bed 1 and a column 2, the column 2 is arranged on the top surface of the bed 1, and two parallel X-axis fixed blocks 11 are fixed on the top surface of the bed 1, An X-axis guide rail 12 is fixed on each X-axis fixing block 11 , and the X-axis guide rail 12 is arranged in a horizontal direction.

[0038] refer to figure 2 with image 3, the bottom end of the column 2 is fixed with two X-axis sliders 21 , and each X-axis slider 21 is slidably connected with the corresponding X-axis guide rail 12 . An X-axis drive assembly 3 is disposed between the two X-axis guide rails 12 , and the X-axis drive assembly 3 can drive the column 2 to move along the X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com