Control method for wind power, thermal power and capacitor coordinated wind and thermal bundling system after direct current block

A wind-fire bundling and control method technology, applied in wind power generation, power transmission AC network, electrical components, etc., can solve the problem of emergency control strategy that does not consider the blocking fault of the UHV DC outgoing channel, and achieve the reduction of wind-fired electric cutting machine The effect of increasing the quantity, improving safety, and optimizing the ratio of wind-fired electric cutting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

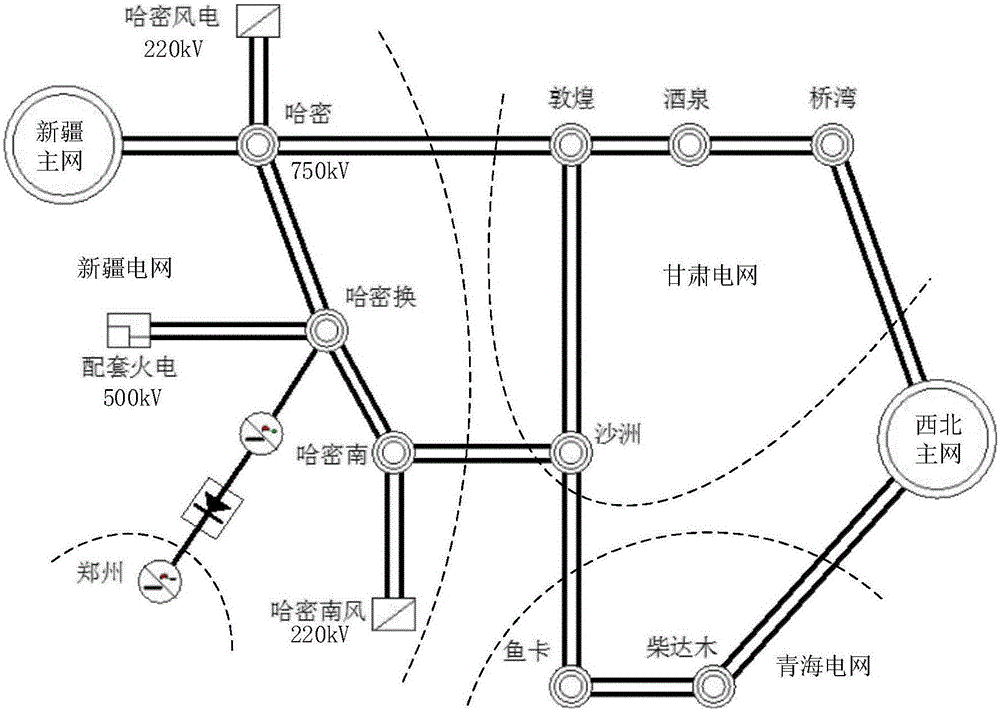

[0058] In this embodiment, the structure of the wind-fire bundling system can be found in figure 2 . The UHV DC rated voltage is ±800kV, and the rectification station is connected to the Xinjiang power grid. The active output of the thermal power unit of the wind-fire bundling system is 6600MW (10×660MW). The active output of wind power is 2850MW. A total of 16 sets of AC capacitors are configured in the UHV DC rectification station, with a total reactive power compensation capacity of 3880Mvar. Assuming that the UHV DC blockage occurs at the 100th cycle, the rectifier station capacitor is blocked and cut off with a delay of 10 cycles, and wind power and thermal power are cut off after a delay of 5 cycles.

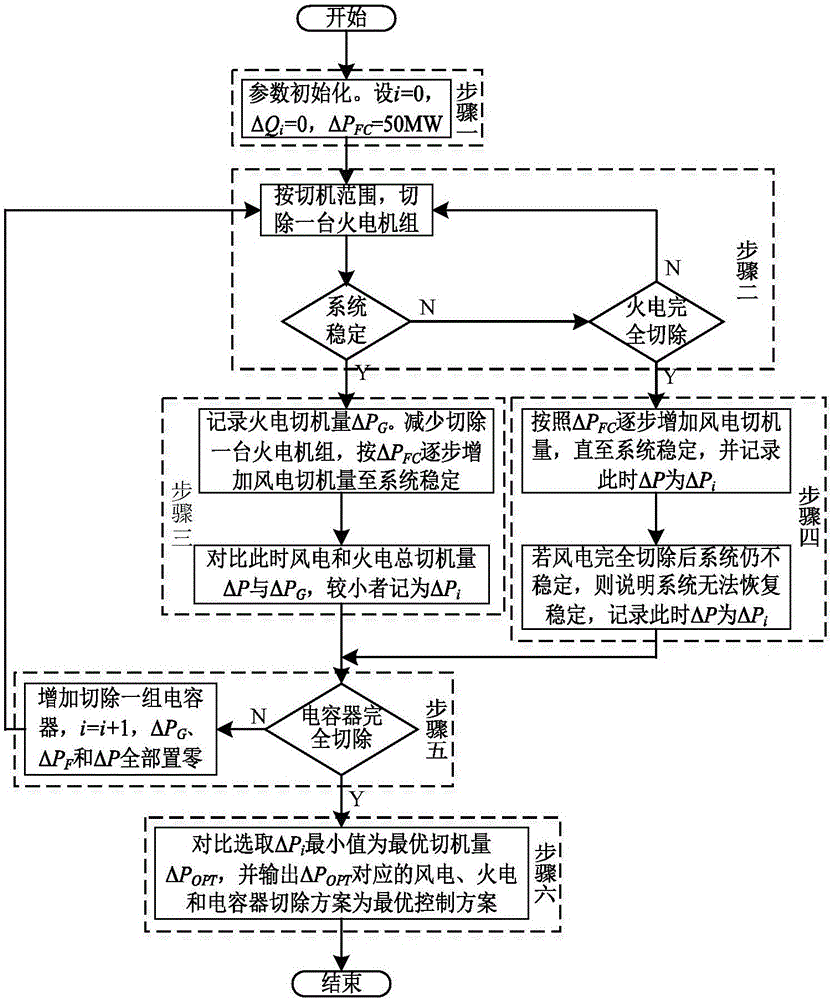

[0059] Step 1, parameter initialization. Let ΔP FC =50MW, i=0, ΔQ i =0.

[0060] When selecting a single cut-off operation, the wind power cut-off amount ΔP FC = 50MW. Supporting capacitors are removed in units of groups, and the number of removed groups i satisf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com