Milling tool path optimization method for low carbon

A tool path, milling technology, applied in the direction of electrical program control, digital control, etc., to achieve the effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In the actual milling process, the length of the tool path affects the processing time. Through path optimization, the actual processing time can be shortened, thereby reducing the consumption of materials and energy in the processing process, and at the same time reducing the generation of waste. There is a direct relationship between the consumption of materials and energy and the amount of waste generated, so route optimization can reduce carbon emissions in the processing process. For the milling of the mold cavity, the machining process often needs to remove a large amount of workpiece material, consumes a lot of electricity, and therefore generates a large amount of carbon emissions. By optimizing the tool path, not only can the processing efficiency of the mold cavity be improved, but at the same time It can also reduce the carbon emissions in the processing process and reduce the processing cost of the enterprise.

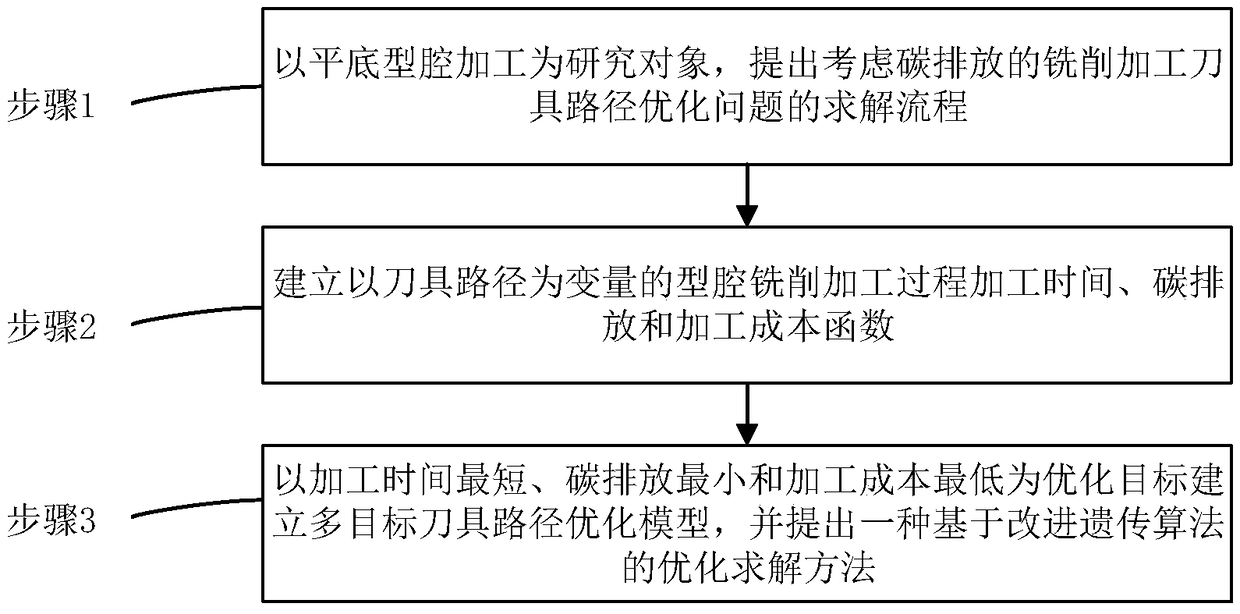

[0083] see figure 1 , the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com