Numerically controlled inclined hole machining device

An oblique hole and machining center technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of unimproved processing efficiency and multiple clamping, avoiding multiple clamping and improving Processing efficiency, the effect of realizing full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to elaborate the content of the present invention, specific examples will be listed below for detailed description.

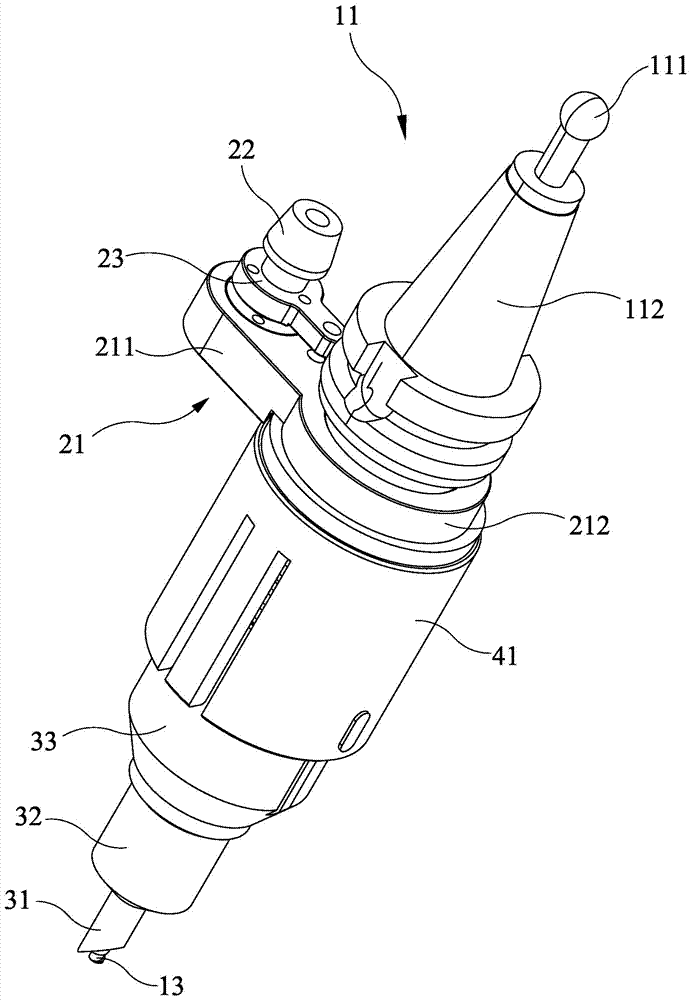

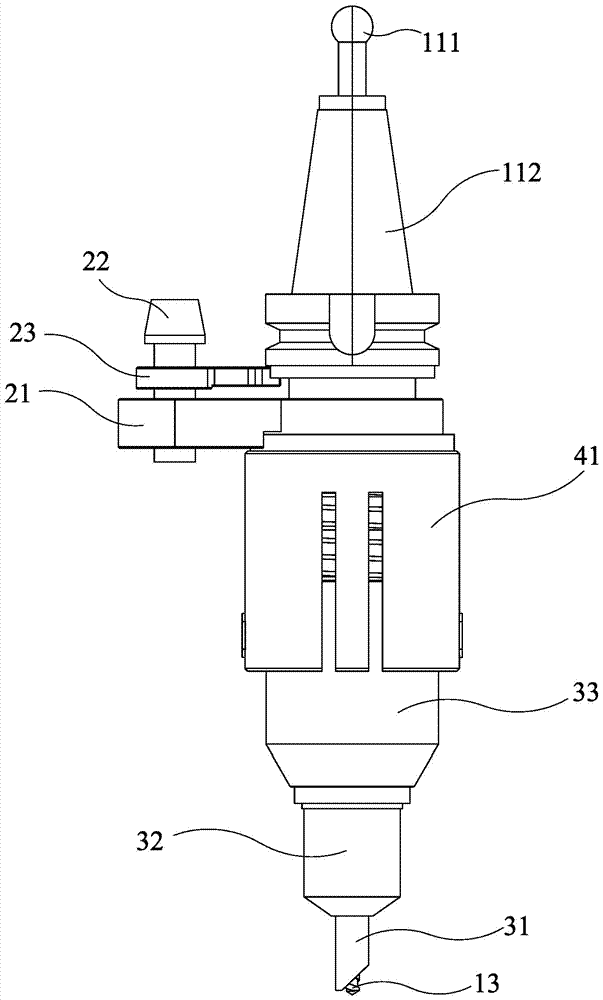

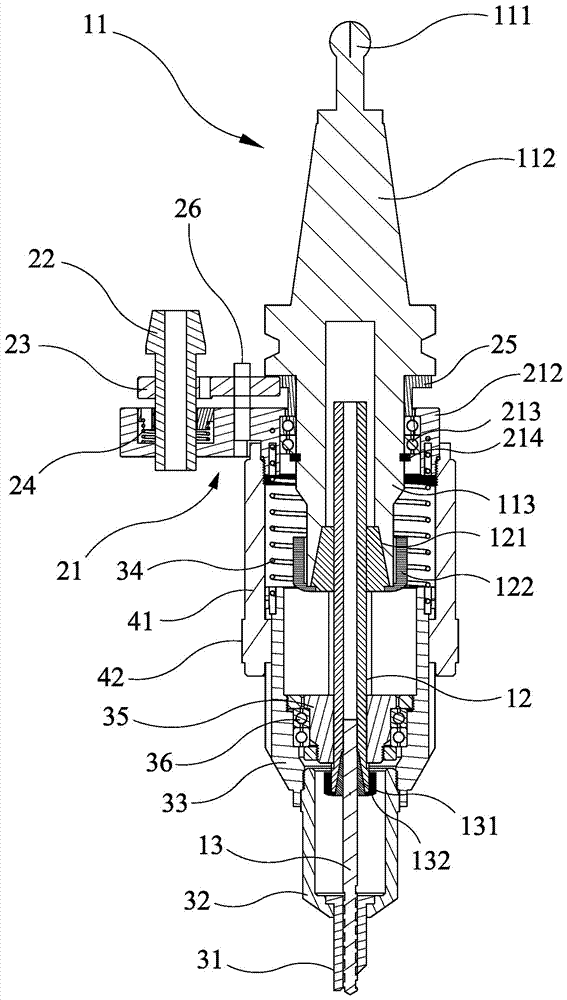

[0023] refer to Figure 1 to Figure 5 As mentioned above, the present invention discloses a CNC machining inclined hole device, which is arranged on the machining center equipment, and specifically includes a positioning mechanism, a guiding mechanism, a sliding mechanism and a drilling mechanism.

[0024] The above-mentioned drilling mechanism includes a cutter head 11 , an external spline shaft 12 and a drill bit 13 . Wherein, the cutter head 11 is provided with a locking portion 111, a positioning cone 112 and a connecting portion 113 connected in sequence, wherein the locking portion 111 and the positioning cone 112 are connected with the main shaft 51 of the machining center equipment, so that the main shaft 51 can The cutter head 11 is driven to rotate, and the connecting part 113 is matched with the positioning mechanism.

[0025] A cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com