Two-shaft linked rotating workbench for numerical control machine tool

A technology of rotary table and CNC machine tool, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. It can solve the problems that cannot meet the requirements of modern product processing accuracy and style, the response frequency of the control system is limited, and the motion control is easy. In case of problems such as vibration, it can achieve the effects of precise positioning and zero return, reduced energy loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

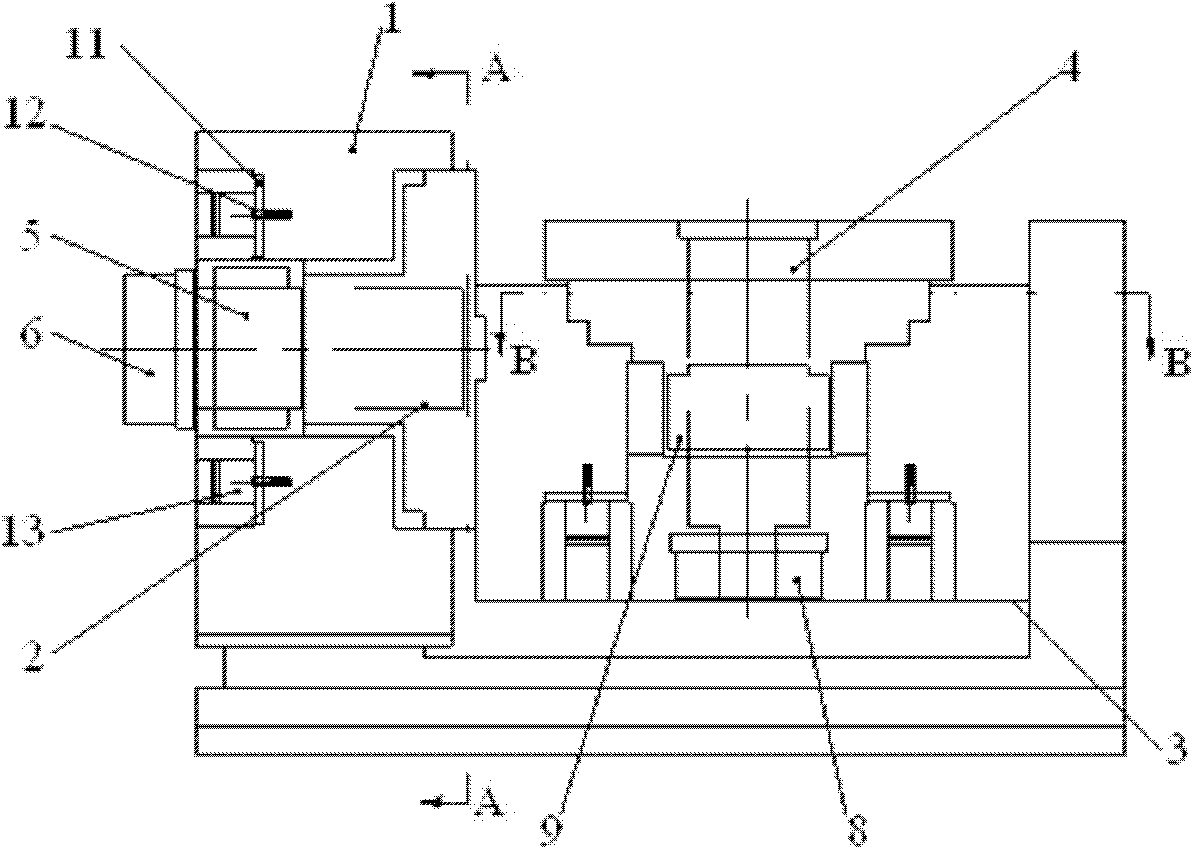

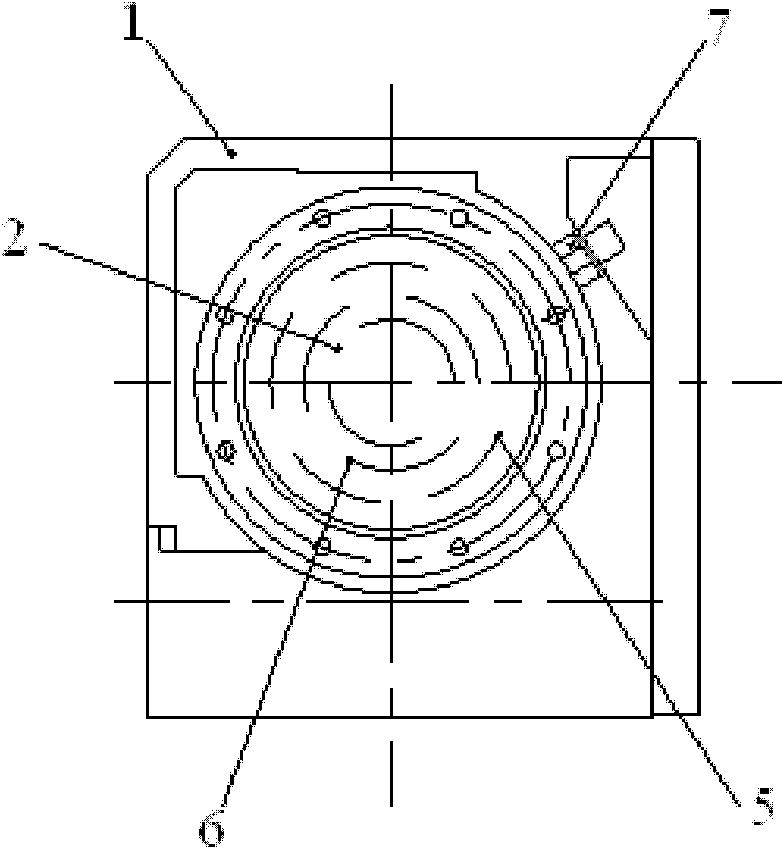

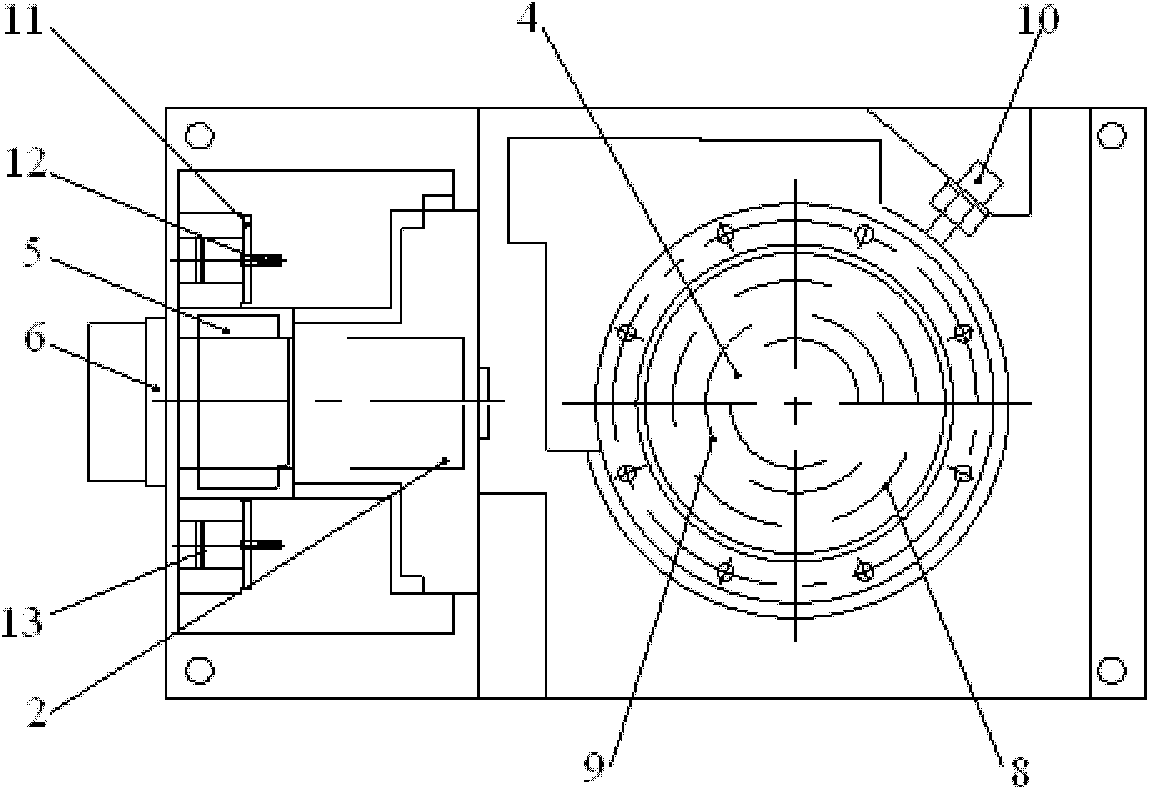

[0018] Such as figure 1 , figure 2 and image 3 The expressed structure of the present invention is a two-axis linkage rotary table of a CNC machine tool. The present invention adopts a three-axis numerical control linkage linear movement, a slide base and a double-axis numerical control linkage rotary table structure, and takes into account the overall rigidity and operating sensitivity of the machine tool, emphatically enhancing the forming principle and process performance optimization of three-dimensional curved surface processing, which can significantly improve the three-dimensional Quality and efficiency in surface machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com