Five-axis numerical control carving machine swinging head

A numerical control engraving machine and swing head technology, applied in the swing head field, can solve the problems of waste of manpower and time, multi-faceted processing of workpieces, etc., and achieve the effects of easy use and maintenance, avoiding multiple clamping, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

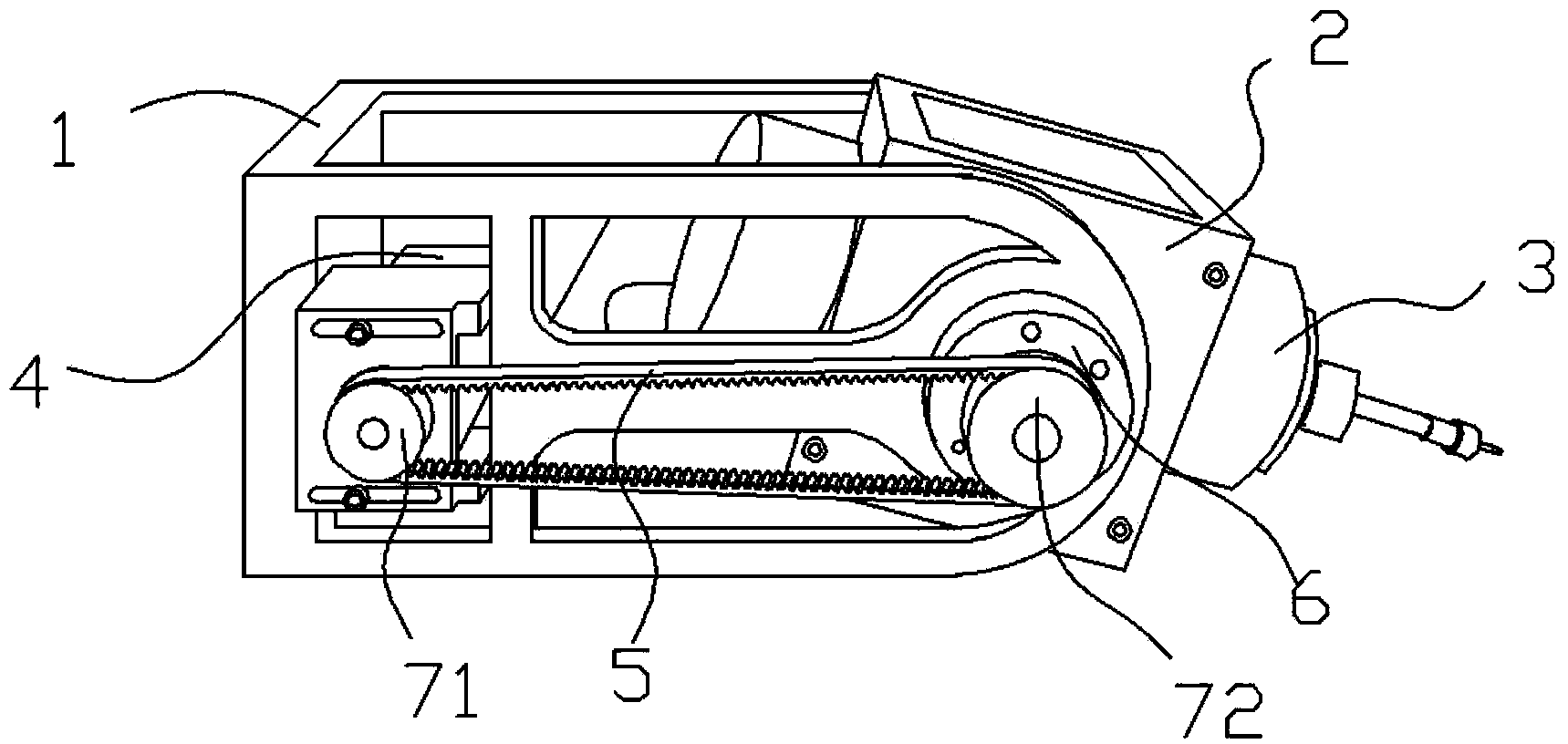

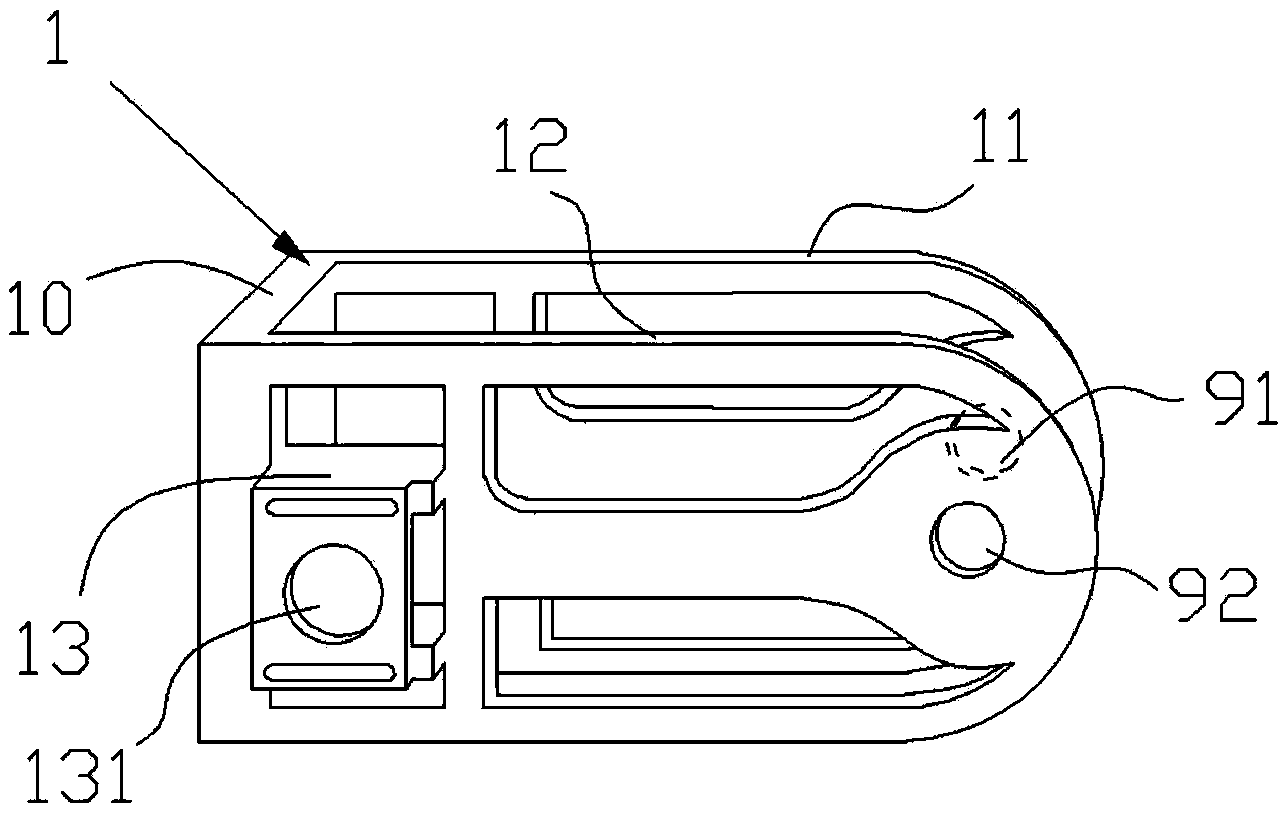

[0011] see figure 1 , is the oscillating head of the five-axis CNC engraving machine provided by the embodiment of the present invention.

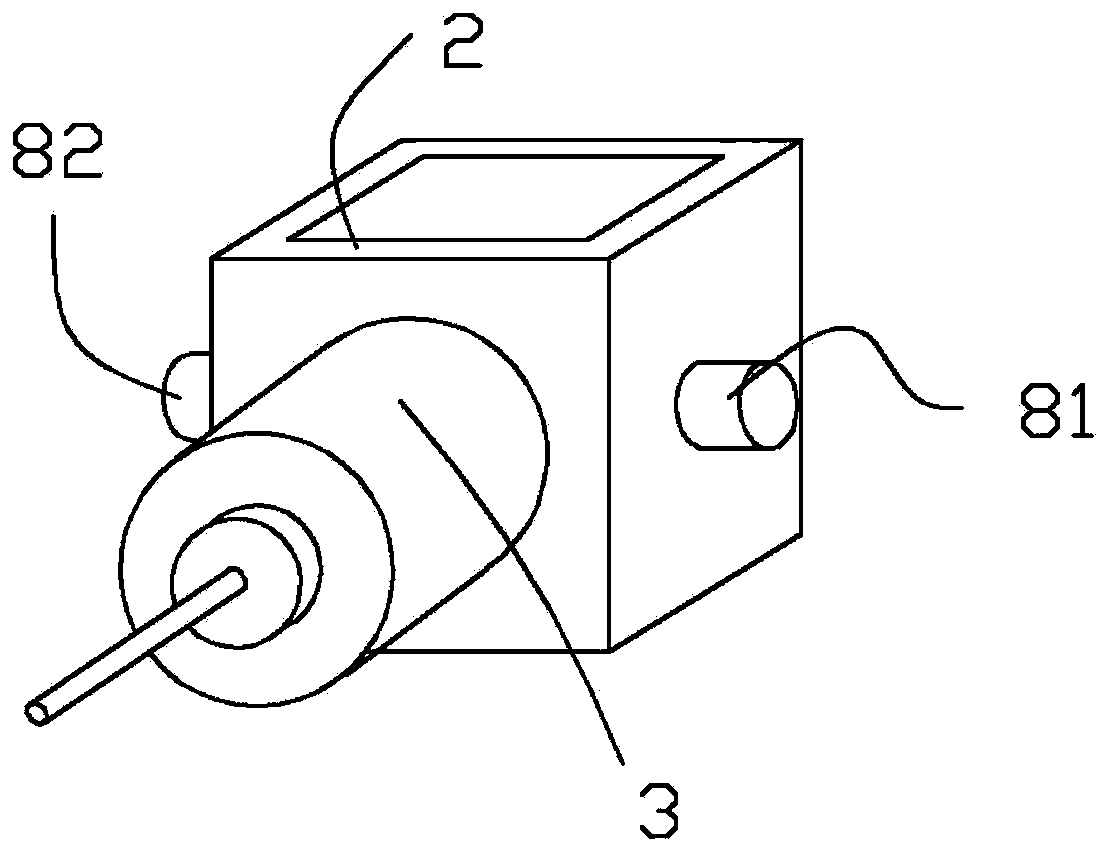

[0012] Below, based on Figure 1~3 The embodiment of the oscillating head of the five-axis CNC engraving machine of the present invention will be described.

[0013] Such as figure 1 , 2 As shown, the fixed frame 1 includes a tailgate 10, a left arm 11, a right arm 12 and a motor mounting frame 13. The left arm 11 and the right arm 12 are respectively vertically welded to both sides of the tailgate 10, and the motor mounting frame 13 is located on the right The afterbody of the arm 12 is welded on the tailgate 10, the center of the motor mounting frame 13 has a circular hole 131, the motor mounting frame 13 is equipped with a servo motor 4, the servo motor 4 is located inside the fixed frame 1, and the transmission of the servo motor 4 The shaft passes through the circular hole 131, and the servo motor 4 is fastened on the motor mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com