A kind of aircraft special-shaped parts clamping auxiliary device and clamping method

An auxiliary device and special-shaped technology, which is applied to metal processing mechanical parts, positioning devices, clamping and other directions, can solve the problems of difficult clamping and processing, affecting processing accuracy, low processing efficiency, etc., to improve cutting accuracy, extend the Service life, the effect of stable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention are described below to facilitate those skilled in the art to understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those skilled in the art, as long as various changes Such changes are obvious within the spirit and scope of the present invention as defined and determined by the appended claims, and all inventions and creations utilizing the inventive concept are within the scope of protection.

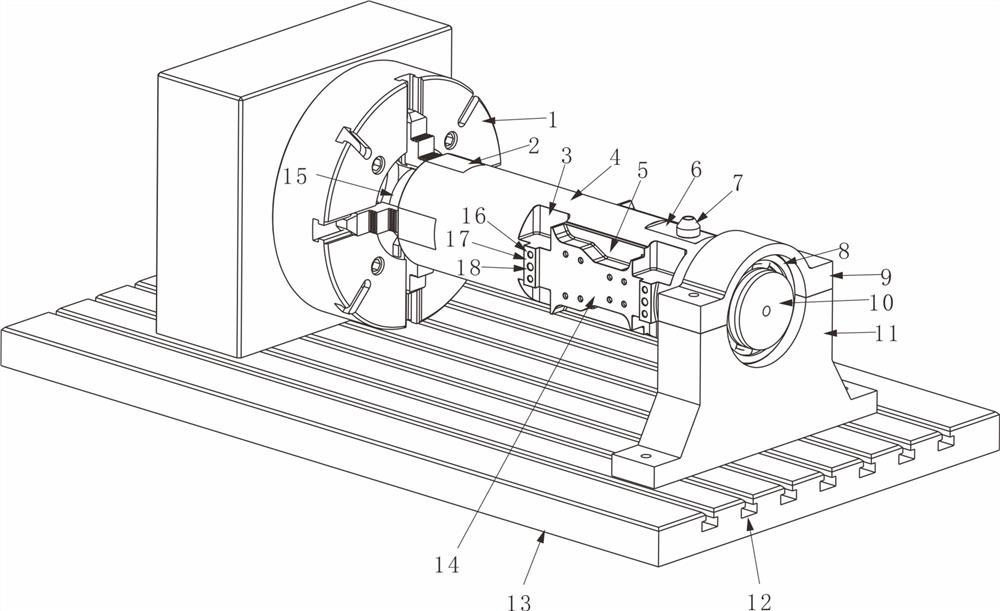

[0034] like figure 1 As shown, the aircraft special-shaped parts clamping auxiliary device of this scheme includes a cylindrical rotating body 4, and the two ends of the rotating body 4 are respectively provided with cylindrical clamping ends 15 and fixed ends 10. The clamping end 15 and the fixed end 10 It is coaxial with the rotary body 4; the clamping end 15 is fixed on the chuck 1 of the machine tool, and the fixed end 10 is mounted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com