Non-stink black denim dyeing technology

A denim, odorless technology, applied in the field of dyeing, can solve the problem of fabrics not smelling bad smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

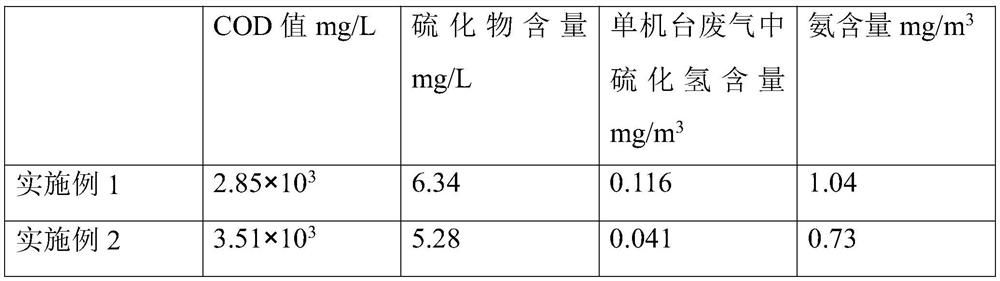

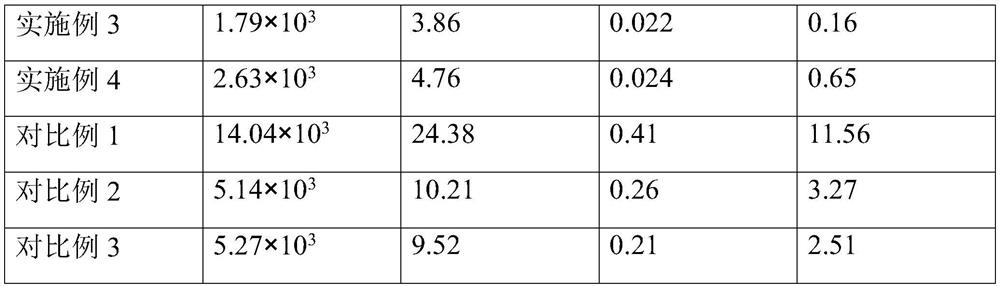

Examples

Embodiment 1

[0022] A kind of dyeing process of odorless black denim, including the wetting step of warp beam of raw yarn, dyeing step, washing step, color fixing step, anti-brittle step, drying and sizing step and splitting step which are continuously completed in one step by sizing and dyeing combined machine The coiling step, wherein the dyeing step is to dip the warp yarn with the dyeing base solution at a temperature of 98°C. The dyeing base solution includes the following components: 105g / L of sulfur black, 25g / L of new composite reducing agent, and 5g of alkali-resistant penetrating agent / L, Taikoo oil 1g / L, caustic soda 35g / L, the new composite reducing agent includes the following components in mass percentage: thiourea dioxide 75wt%, glucose 20wt%, sodium nitrite 5wt%.

[0023] The wetting step of the warp beam of the raw yarn in this embodiment is to soak the warp yarn with the treatment bottom solution, and the temperature is 30°C.

[0024] In this embodiment, the treated bott...

Embodiment 2

[0031]A kind of dyeing process of odorless black denim, including the wetting step of warp beam of raw yarn, dyeing step, washing step, color fixing step, anti-brittle step, drying and sizing step and splitting step which are continuously completed in one step by sizing and dyeing combined machine The coiling step, wherein the dyeing step is to dip the warp yarn with the dyeing base solution at a temperature of 90°C. The dyeing base solution includes the following components: sulfur black 95g / L, new composite reducing agent 35g / L, alkali-resistant penetrating agent 1g / L, Taikoo oil 5g / L, caustic soda 25g / L, the new composite reducing agent includes the following components in mass percentage: thiourea dioxide 30wt%, sucrose 60wt%, acrylamide 10wt%.

[0032] The wetting step of the warp beam of the raw yarn in this embodiment is to soak the warp yarn with the treatment bottom solution, and the temperature is 20°C.

[0033] In this embodiment, the treatment bottom liquid is an ...

Embodiment 3

[0040] A kind of dyeing process of odorless black denim, including the wetting step of warp beam of raw yarn, dyeing step, washing step, color fixing step, anti-brittle step, drying and sizing step and splitting step which are continuously completed in one step by sizing and dyeing combined machine The coiling step, wherein the dyeing step is to dip the warp yarns with a dyeing base solution at a temperature of 95°C. The dyeing base solution includes the following components: 100 g / L of sulfur black, 30 g / L of a new composite reducing agent, and 3 g of an alkali-resistant penetrating agent / L, Taikoo oil 3g / L, caustic soda 30g / L, the new composite reducing agent includes the following components in mass percentage: thiourea dioxide 50wt%, glucose 30wt%, sodium nitrite 10wt%, acrylamide 10wt%.

[0041] The wetting step of the warp beam of the raw yarn in this embodiment is to soak the warp yarn with the treatment base solution, and the temperature is 25°C.

[0042] In this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com