The original ecological natural color treatment process of the fabric

A processing technology and original ecological technology, applied in the processing of textile materials, continuous processing of textile materials, fiber processing, etc., can solve the problems of complex process, high pollution, high energy consumption, etc., achieve COD index reduction, wide adaptability, The effect of chemical convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

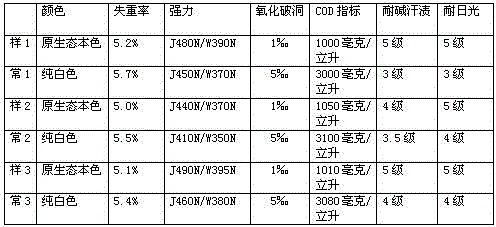

[0020] Take 1 ton of towel fabric woven from cellulose fiber and regenerated fiber respectively, and use the treatment process of this application to process three times (sample 1, sample 2, sample 3),

[0021] Specific implementation steps:

[0022] ⑴Water wash after weaving: normal temperature, water-to-bath ratio 1:6, wash time 15 minutes; one wash washes away the impurities on the fabric and reduces the amount of tea saponin in the next process.

[0023] (2) Tea saponin treatment: immerse the fabric to be treated in 93-103°C working solution for 75-85 minutes, the bath ratio is 1:5, the working solution is prepared by adding 4-6% of the fabric weight tea saponin at 8- Dissolve in warm water at 35-45°C within 12 minutes and melt. After melting, add the working fluid into the overflow machine and raise the temperature to 93-103°C at 1.5°C per minute;

[0024] ⑶Secondary water washing: normal temperature, water-to-bath ratio is 1:6, and water washing time is 15 minutes;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com